Full-automatic liquid containing and outputting device

An output device and fully automatic technology, which is applied in the chemical industry, can solve problems such as complicated procedures, pressure bursting of barrels, and neglect of the quality of packaging barrels, etc., to achieve the effect of reducing operation difficulty, low cost, and improving convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

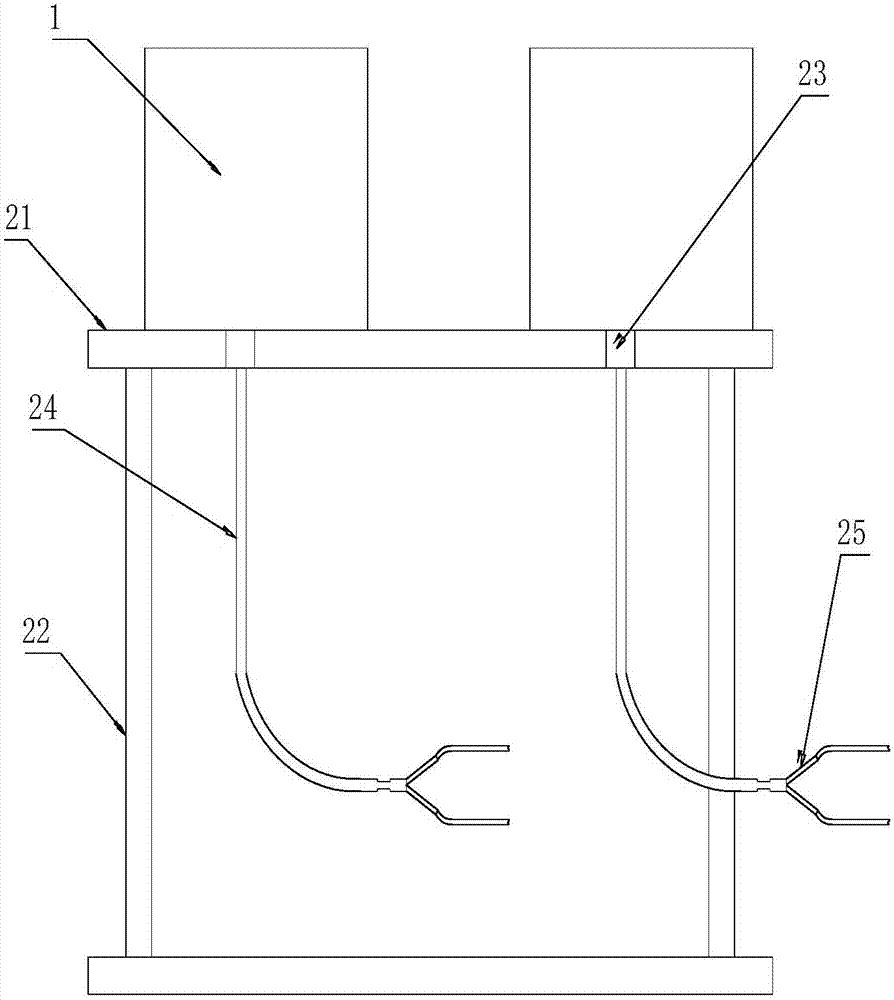

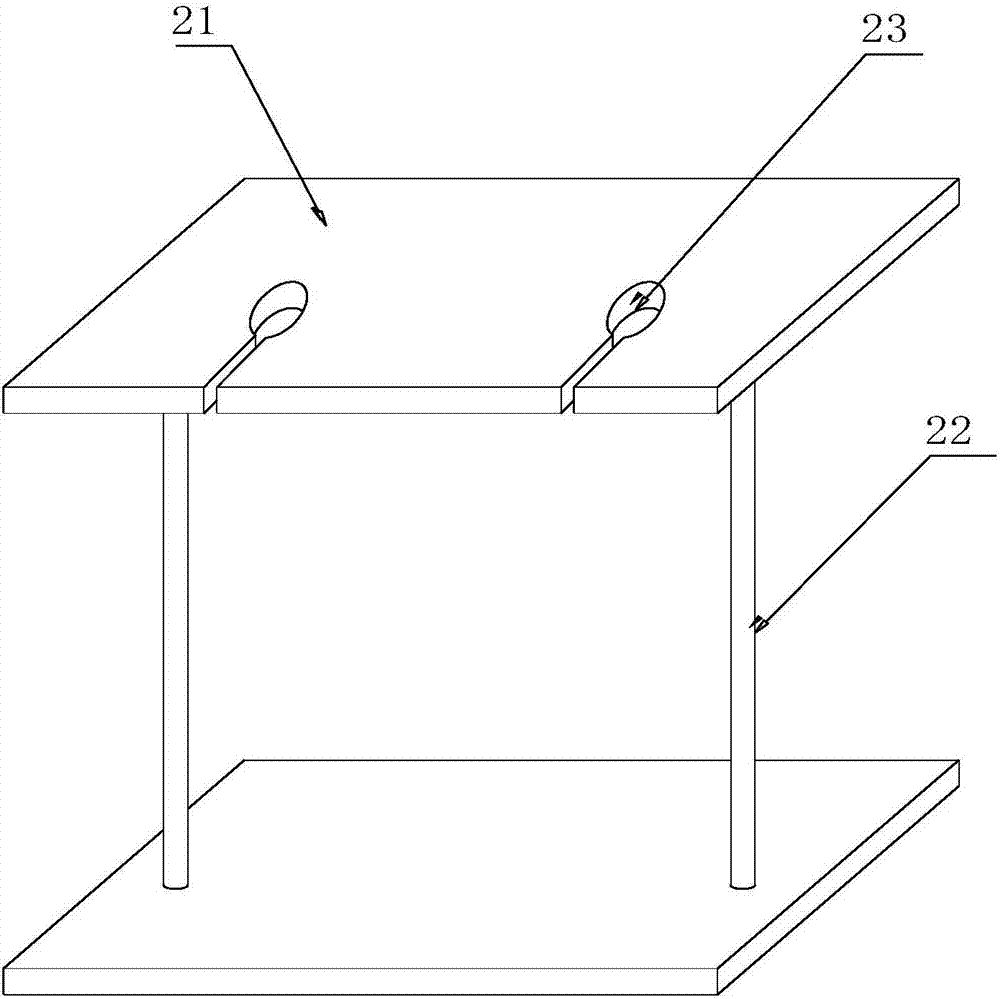

[0058] Such as Figures 1 to 2 As shown, a fully automatic liquid container and output device includes a liquid container and a pipeline 24, and also includes a lifting mechanism for lifting the liquid container to a preset height. The liquid container is composed of a bag and a packing box. The bag is provided with an interface unit for connecting the pipeline 24, and the packing box is provided with an openable opening mechanism for the interface unit to protrude from.

[0059] This embodiment adopts the combination of the lifting device, the packing box and the bag, and realizes the self-draining of the industrial liquid through the self-weight of the fluid.

[0060] It is very important that this solution avoids the problem that the traditional barreled container needs to be pressurized and the bagged container needs to transfer the liquid in advance, and the bagged liquid without a fixed shape is fixed through a tangible packing box, so that workers can The automatic dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com