Lead core damping basin rubber bearing and its damping method

A rubber bearing and lead core technology is applied in the field of bridge engineering vibration reduction, which can solve the problems of increasing the plane size of the upper and lower bottom plates of the bearing, high requirements for the assembly of cover beams and pier columns, affecting the popularization and practicality of the bearing, etc. The effect of good vibration energy dissipation effect, compact structure and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

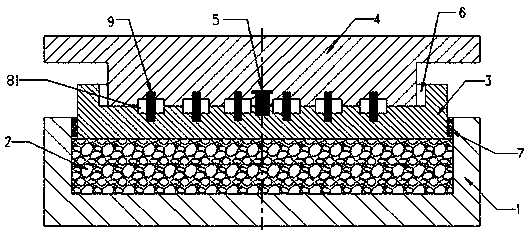

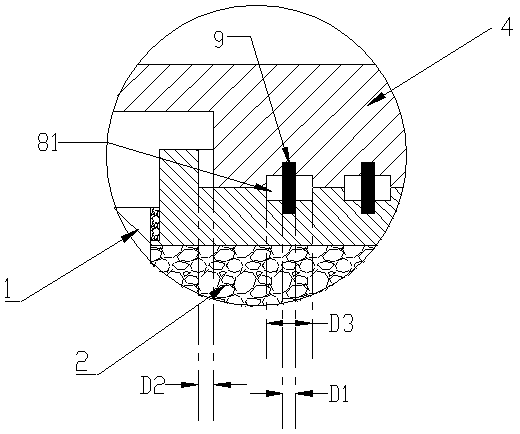

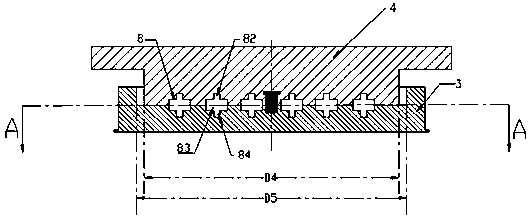

[0026] Such as Figure 1 to Figure 4 As shown, the lead-core damping basin-type rubber support includes a horizontally arranged bottom basin 1, a rubber pad 2 arranged in the bottom basin 1, a piston 3 placed on the rubber pad 2 and protruding from the bottom basin 1, and a set On the upper support plate 4 on the piston 3, the piston 3 is a "concave" shape with an upward opening. The upper support plate 4 is inserted into the upward opening of the piston 3 and protrudes from the piston 3. The upper support plate 4 and the The piston 3 is fixed by the vertical shear pin 5, the upper support plate 4 is spaced from the inner side of the piston 3 to form a circular seismic displacement groove 6, and the inner side wall of the bottom basin 1 and the piston 3 are clamped with a rubber ring 7 , a reserved cavity 8 is provided between the upper support plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com