Boat-shaped pipe section towing protection tool and construction method thereof

A technology for protecting tooling and construction methods, which is applied in the directions of pipeline laying and maintenance, pipes/pipe joints/pipes, mechanical equipment, etc. The effect of quality, high social benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

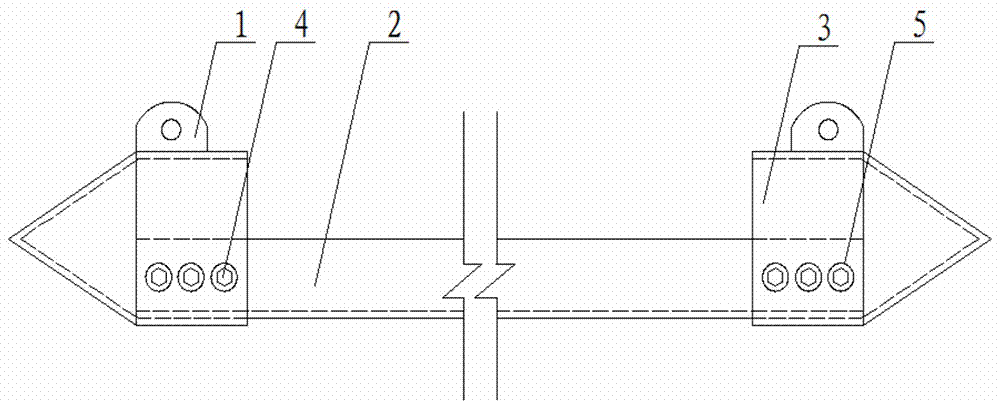

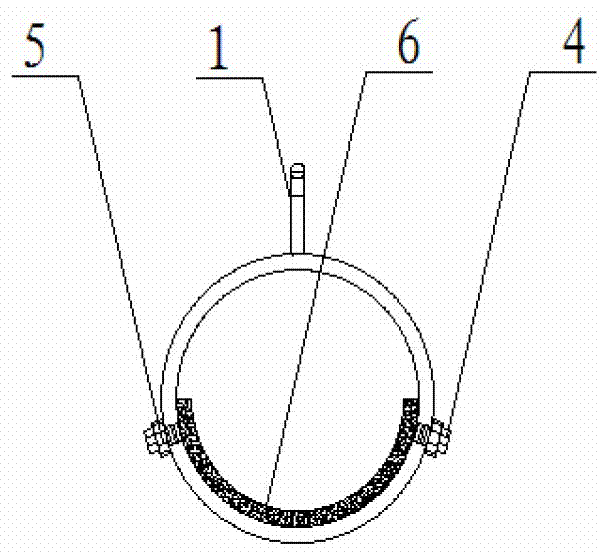

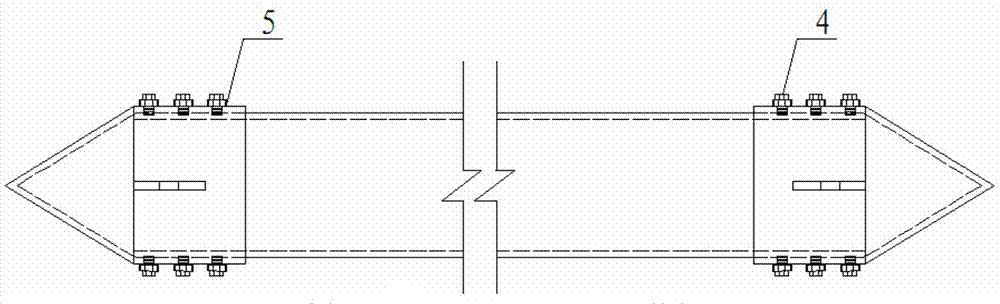

[0025] like Figure 1~3 As shown, a boat-shaped pipe section traction protection tool includes a pipe section protection groove 2, a pipe section protection cap 3 and a traction ring 1; The two ends of the protective groove 2 are respectively connected with a pipe section protection cap 3; the pipe section protection cap 3 is made up of a cap tip and a cap section, the cap tip is tapered, the cap section is tubular, and the tapered tip of the cap tip faces The outer and cone bottoms are connected to one end of the cap section, and the other end of the cap section is fixedly connected to the pipe section protection groove 2; the middle part of the traction ring 1 is provided with a through hole, and a traction ring 1 is fixedly connected to the cap section of each pipe section protection cap 3.

[0026] The pipe section protection groove 2 is formed by longitudinally cutting the entire pipe section. The length of the pipe section protection groove is greater than the length of ...

Embodiment 2

[0032] like Figure 4 As shown, the construction method of the boat-shaped pipe section traction protection tool in embodiment 1 uses the boat-shaped pipe section traction protection tool to transport the pipe section to be installed along the hillside, including the following construction steps:

[0033] 1) Control the excavation depth of the pipe trench according to the design requirements, and trim the trenches on both sides of the pipe trench leading to the top of the mountain, so as to meet the feasible conditions for the traction and protection tooling of personnel and boat-shaped pipe sections;

[0034] 2) Set up two hoists 7 at the foot of the mountain, and anchor the pulley 8 at the position where the direction changes on the top of the mountain and on the slope; The anchor method should be firm and reliable for deep-buried anchorage;

[0035] 3) Put the pipe section to be installed into the boat-shaped pipe section traction protection tool 9: Lay the rubber pad 6 on...

Embodiment 3

[0039] In order to better understand method steps, purpose and function of the present invention, below in conjunction with appendix Figure 4 , taking the installation and welding of the fire-fighting pipeline from a high-level pool on the top of a mountain in Xichang to a building at the foot of the mountain as an example to illustrate:

[0040] In the renovation project of a certain project in Xichang, it is necessary to install the fire-fighting pipeline from the 1# high level pool to the 2# room. The total length of the pipeline is 288 meters, and the vertical height difference is 102 meters. All of them are laid along the steep hillside. The fire-fighting pipes to be installed on site have a large diameter and a single weight of more than 500 kilograms. DN400 stainless steel pipes are used. Each pipe section is 6m long. It is difficult to transport the pipe sections to the installation location by manpower. The traditional rolling bar displacement construction The metho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com