Sheet-processing machine having a deliverer, and method for depositing sheets

An output device and a single-sheet technology, which is applied in the field of stacking single-sheets, and can solve the problems that skewed single-sheets cannot be detected, waste pages are time-consuming, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

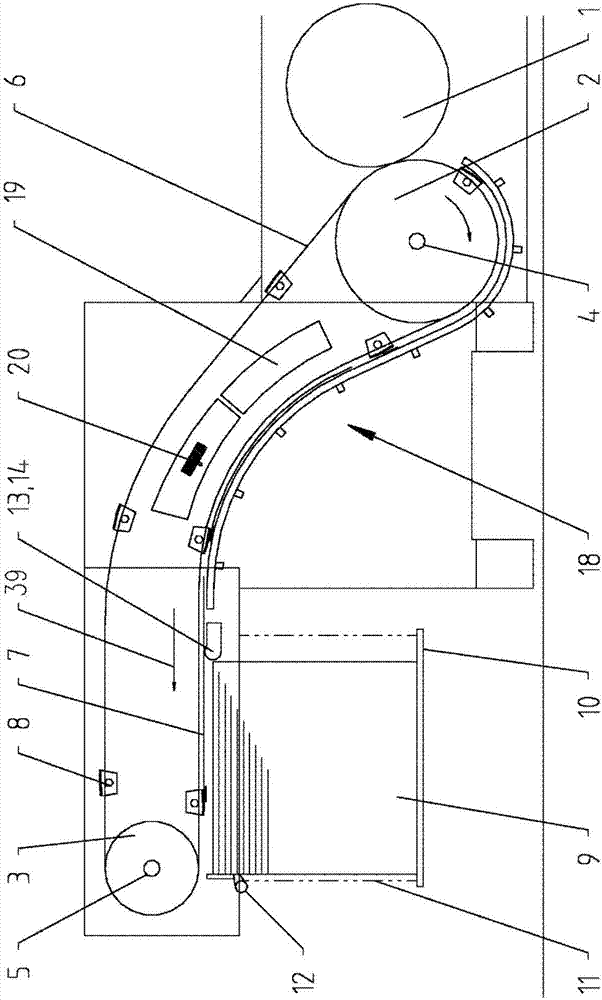

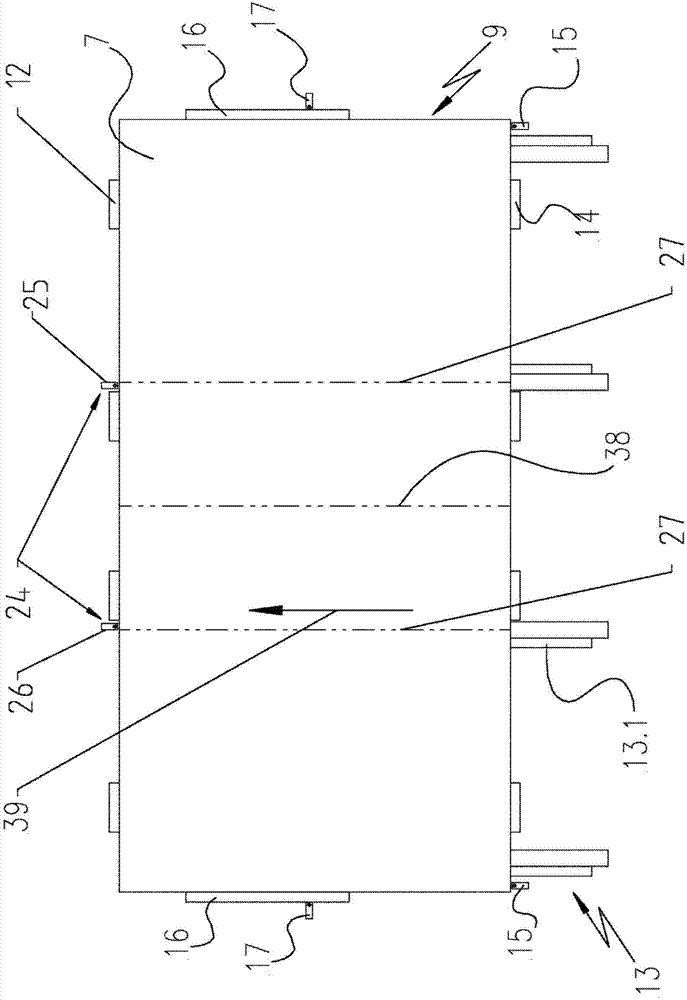

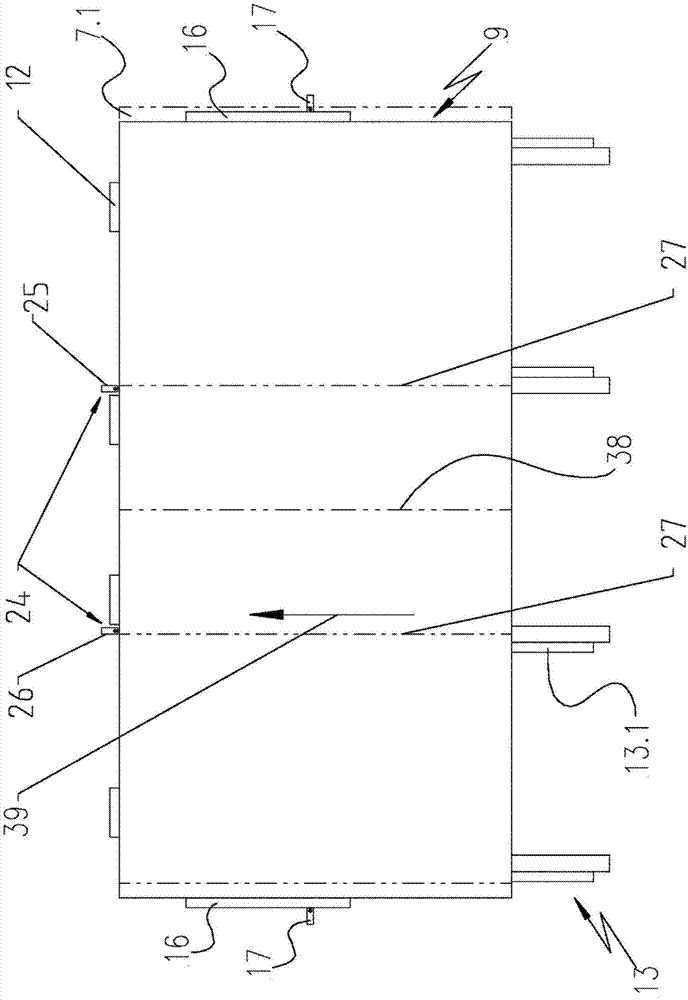

[0060] exist figure 1 shows the output device of a sheet-fed processing machine, here in particular a sheet-fed printing press, in particular a sheet-fed offset rotary printing press, preferably constructed in a block and row configuration. Such machines are correspondingly operated with the lithographic method, wherein other printing methods, such as screen printing, can also be integrated in the machine. In the arrangement of the machine, the individual sheets 7 are gripped at the front edge by means of the gripper system of the rotating cylinders and handed over between the cylinders with the grippers locked. In the printing unit, the individual sheets 7 are each substantially inked with printing ink in the printing nip formed by the cylinder and the blanket cylinder. In addition, one or more varnishing devices are provided, in which the individual sheets 7 can be varnished by a varnishing forme cylinder. The cylinders arranged in the machine can be designed as single-siz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com