Railway track bolt automatic screwing and oiling trolley

A railway track and bolt technology, applied in the direction of track, track laying, track maintenance, etc., can solve the problems of working environment impact, high vibration frequency, and no bolt pre-tightening force, etc., to save manpower, improve efficiency, and achieve a high degree of automation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

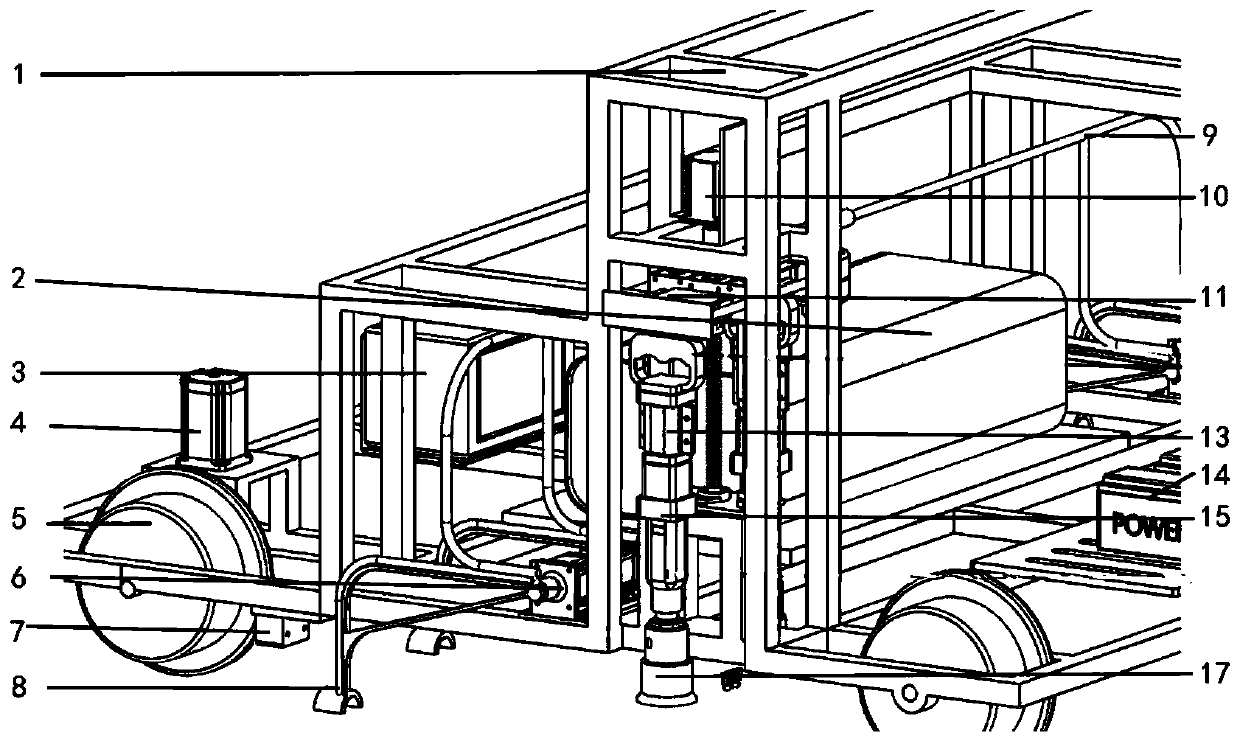

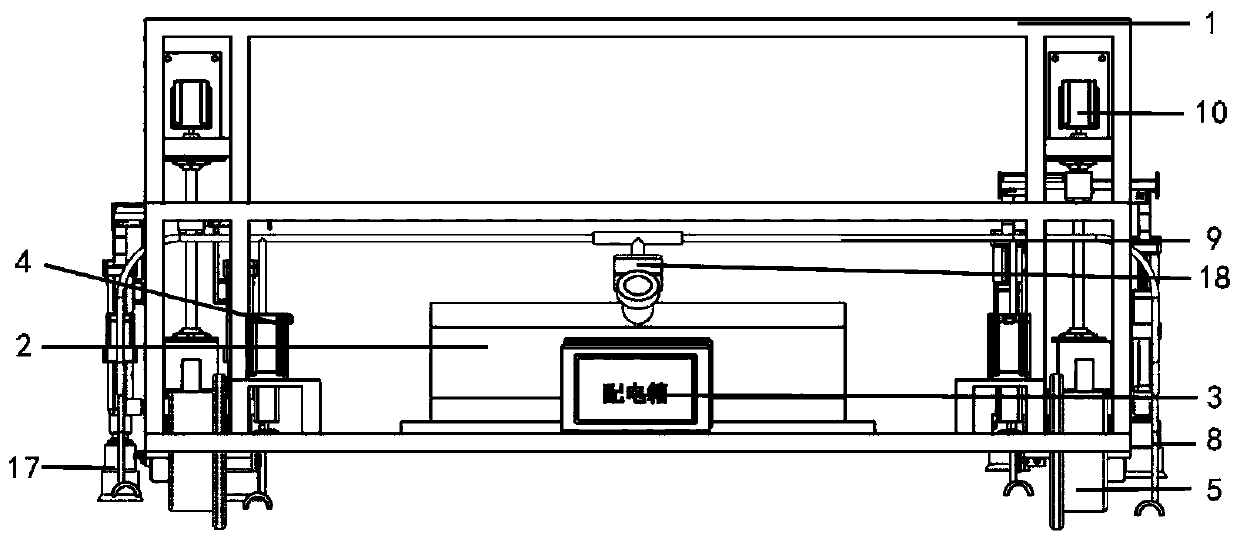

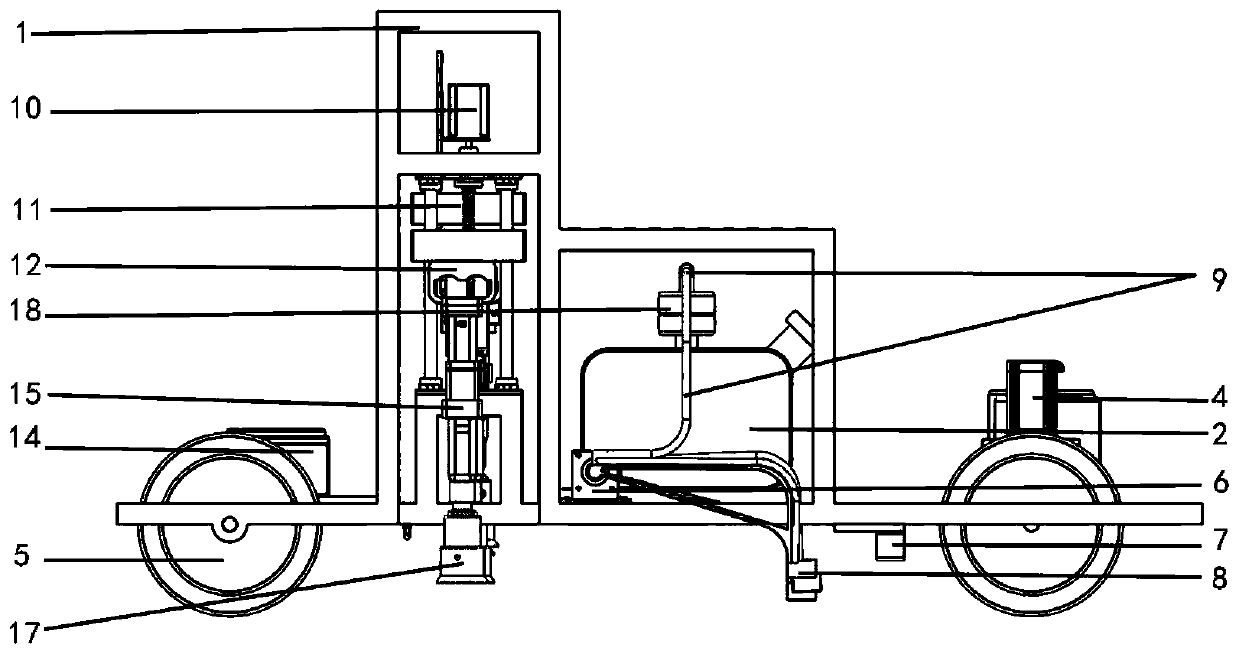

[0037] The present invention will be further described below in conjunction with accompanying drawing.

[0038] Such as Figure 1-15 As shown, the present embodiment provides a kind of railway track bolt automatic screwing and oiling trolley, comprises traveling device, and traveling device comprises frame 1, is provided with traveling wheel 5 symmetrically on both sides of frame, on frame 1 A bolt detection sensor 7, a distribution box 3, a power supply box 14, a bolt screwing device and a bolt oiling device are provided, and the bolt screwing device includes a bearing platform 12 on which a screw vertical movement mechanism is arranged. , the carrying platform is threadedly connected with the leading screw of the vertical movement mechanism of the leading screw, and X-Y adjustment platforms 11 are arranged symmetrically on both sides of the carrying platform 12, and the X-Y adjustment platform 11 is connected with the carrying platform 12 by sliding. The lower end of 11 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com