A kind of sandwich structure multilayer gel polymer electrolyte for lithium ion battery and preparation method thereof

A gel polymer and lithium-ion battery technology, applied in electrolytes, solid electrolytes, non-aqueous electrolytes, etc., can solve the problems of tedious alternate spin coating process, difficult precise control and improvement of component content, and achieve high ion conductivity efficiency and high mechanical strength, good electrolyte compatibility, and the effect of expanding the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

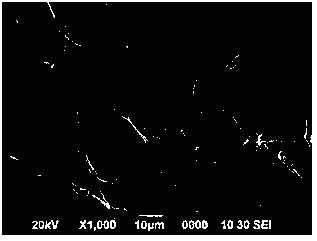

Image

Examples

Embodiment 1

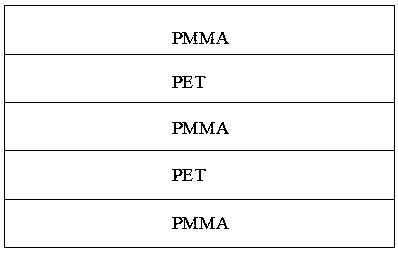

[0036] A kind of PMMA sandwich structure multilayer gel polymer electrolyte for lithium ion battery, described gel polymer electrolyte is a sandwich five-layer structure, is formed by alternate compounding of PMMA film and PET film, wherein PMMA film is placed in sandwich five-layer structure The upper and lower surfaces of the PET film are placed in the inner layer of the sandwich five-layer structure, which is alternately compounded with the PMMA film.

[0037] The gel polymer electrolyte is prepared by electrospinning, and the specific steps are as follows:

[0038] (1) Dissolve PMMA polymer in tetrahydrofuran (THF), reflux and stir at 65°C until the solution is clear and transparent, then continue to stir at room temperature for 2 hours to obtain A membrane spinning solution, the concentration of A membrane spinning solution is 30 %;

[0039] (2) Dissolve the PET polymer in chloroform, reflux and stir at 60°C until the solution is clear and transparent, and then stir at r...

Embodiment 2

[0052] A kind of PMMA sandwich structure multilayer gel polymer electrolyte for lithium ion battery, described gel polymer electrolyte is a sandwich three-layer structure, is formed by alternate compounding of PMMA film and PET film, wherein PMMA film is placed in sandwich three-layer structure The upper and lower surface layers, the PET film is placed in the middle layer of the sandwich three-layer structure.

[0053] The gel polymer electrolyte is prepared by electrospinning, and the specific steps are as follows:

[0054] (1) Dissolve the PMMA polymer in hexafluoroisopropanol, reflux and stir at 55°C until the solution is clear and transparent, and then continue to stir at room temperature for 5 hours to obtain the A membrane spinning solution. The concentration of the A membrane spinning solution is 20%;

[0055] (2) Dissolve the PET polymer in hexafluoroisopropanol, reflux and stir at 50°C until the solution is clear and transparent, and then stir at room temperature for...

Embodiment 3

[0063] A kind of PMMA sandwich structure multilayer gel polymer electrolyte for lithium ion battery, described gel polymer electrolyte is a sandwich five-layer structure, is formed by alternate compounding of PMMA film and PCL film, wherein PMMA film is placed in sandwich five-layer structure The upper and lower surface layers of the PCL film are placed in the inner layer of the sandwich five-layer structure, which is alternately compounded with the PMMA film.

[0064] The gel polymer electrolyte is prepared by electrospinning, and the specific steps are as follows:

[0065] (1) Dissolve PMMA polymer in methyl ethyl ketone solvent, reflux and stir at 75°C until the solution is clear and transparent, then continue to stir at room temperature for 2 hours to obtain A membrane spinning solution, the concentration of A membrane spinning solution is 5% ;

[0066] (2) Dissolve the PCL polymer in acetone, reflux and stir at 30°C until the solution is clear and transparent, and then s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap