Manufacturing method of halitosis and tooth-decay preventing toothpaste

A manufacturing method and technology of toothpaste, which are applied in the directions of dentistry, oral care, medical science, etc., to achieve the effect of changing the condition of bad breath and dental caries, the technology is simple, and the effect is obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

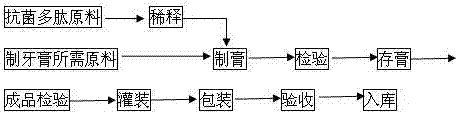

[0033] A kind of anti-halitosis and dental caries children's toothpaste production technological process of protecting children's teeth is as follows:

[0034] (1) Preparation of antibacterial polypeptide raw materials and preparation of toothpaste raw materials,

[0035] (2) Add antibacterial polypeptide raw materials in the toothpaste production process, so that antibacterial polypeptide components can be added to toothpaste. The preparation of the antibacterial polypeptide of the present invention includes dissolving the concentrated crystalline powder of the antibacterial polypeptide with a content of 80-100% in pure water, and diluting it to a concentration of 0.0005-2% for later use; the toothpaste raw materials include abrasives, cleaning agents, Thickener, foaming agent, flavoring agent and other small materials, the production process is followed by paste making (paste manufacturing), inspection, paste storage, finished product inspection, packaging, outer packaging, ...

Embodiment 2

[0038] A kind of middle-aged and elderly toothpaste its production process is as follows:

[0039] (1) Preparation of antibacterial polypeptide raw materials and preparation of toothpaste raw materials,

[0040] (2) Add antibacterial polypeptide raw materials in the toothpaste production process, so that antibacterial polypeptide components can be added to toothpaste. The preparation of the antibacterial polypeptide of the present invention includes dissolving the concentrated crystalline powder of the antibacterial polypeptide with a content of 80-100% in pure water, and diluting the solution to a concentration of 0.001-3% for later use; the production process of the toothpaste is followed by paste manufacturing, Inspection, paste storage, finished product inspection, packaging, outer packaging, warehousing steps, and the antibacterial polypeptide dilution solution is added in the paste making step, so that the antibacterial polypeptide components are evenly distributed in th...

Embodiment 3

[0043] A kind of toothpaste that prevents halitosis and dental caries its production technological process is as follows:

[0044] (1) Preparation of antibacterial polypeptide raw materials and preparation of toothpaste raw materials,

[0045](2) Add antibacterial polypeptide raw materials in the toothpaste production process, so that antibacterial polypeptide components can be added to toothpaste. The preparation of the antibacterial polypeptide of the present invention includes dissolving the concentrated crystalline powder of the antibacterial polypeptide with a content of 80-100% in pure water, and diluting the solution to a concentration of 0.0015-5% for later use; the toothpaste production process is followed by paste production , inspection, paste storage, finished product inspection, packaging, outer packaging, and warehousing steps, and the antibacterial polypeptide dilution solution is added in the paste making step, so that the antibacterial polypeptide ingredients ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com