Safe cable equipment

A cable and safety technology, applied in the field of safe cable equipment, can solve the problems of uneven mixing of cleaning liquid, complicated flushing equipment, large floor area, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

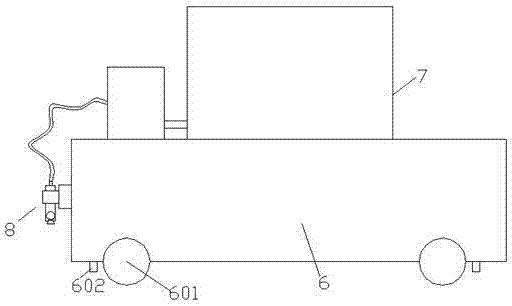

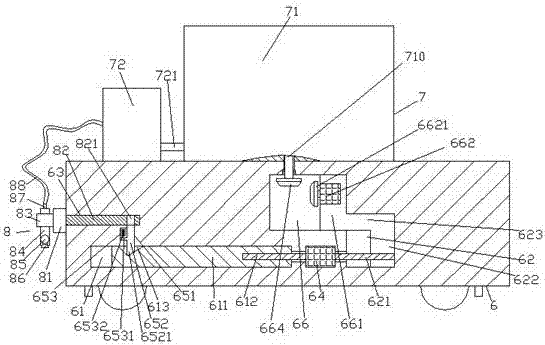

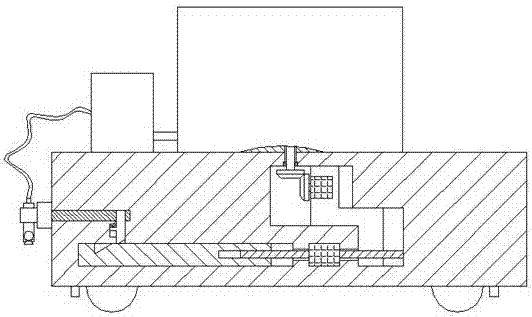

[0021] Such as Figure 1-Figure 6 As shown, a safe cable equipment of the present invention includes a flushing base 6, a flushing device 7 arranged on the top of the flushing base 6, and a flushing frame device 8 installed on the left side of the flushing base 6, the The flushing device 7 is composed of a cleaning liquid storage box 71 and a pressurized pump 72. The cleaning liquid storage box 71 is rotated and connected with a downwardly extending agitation shaft 710. The flushing base 6 below the cleaning liquid storage box 71 The first slide chamber 66 is arranged inside, the tail end of the bottom of the stirring shaft 710 extends into the first slide chamber 66 and the tail end is fixed with a first cone wheel 664, the right side of the first cone wheel 664 A first sliding block 661 is slid and connected in the first sliding chamber 66 of the first sliding block, and a first motor 662 is arranged on the left side of the upper side of the first sliding block 661, and a pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com