Multi-channel flaky material feeding method and device

A multi-channel, sheet material technology, applied in the direction of loading/unloading, transportation and packaging, conveyor objects, etc., can solve the problems of high price, high manufacturing cost, huge equipment, etc., and achieve the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

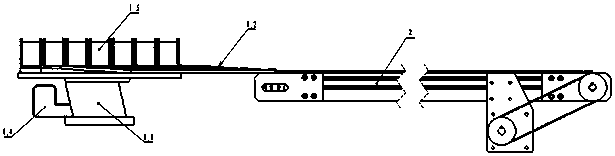

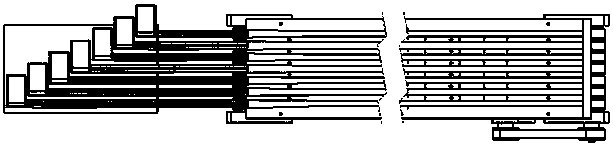

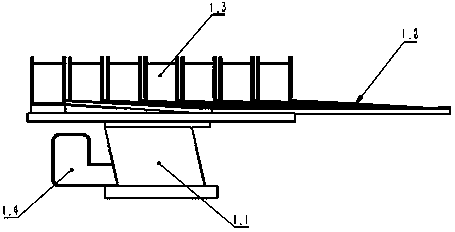

[0021] see figure 1 ~5, a kind of multi-channel sheet material feeding method that the present invention relates to, described method is:

[0022] Step 1. Stack sheet materials of different specifications in different storage boxes 1.3;

[0023] Step 2: Start the linear feeder, the vibration of the linear feeder main body 1.1 drives the linear track 1.2 and the material storage box 1.3 to vibrate, so that the sheet materials in the material storage box 1.3 are arranged and transported along the channels in the respective linear track 1.2;

[0024] Step 3. The material on the linear track 1.2 is transferred to the conveyor belt on the conveyor mechanism 2, the conveyor mechanism 2 is started, and the sheet materials on each conveyor belt move with the conveyor belt until it is held by the stopper above the tail of the conveyor belt. The sheet materials behind are connected end to end and covered with the conveyor belt of the transmission mechanism 2;

[0025] A multi-channel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com