Damage protection device and method for aluminum alloy plate transportation

A technology of aluminum alloy plate and protective device, which is applied in the direction of transportation and packaging, packaging, and containers to prevent mechanical damage, etc. It can solve the problems of processing errors that cannot be eliminated, aluminum alloy plate appearance inspection failure, and relative sliding between layers. Or collision and other problems to achieve the effect of avoiding black spots, avoiding reciprocating sliding friction, reducing the transportation damage rate and

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

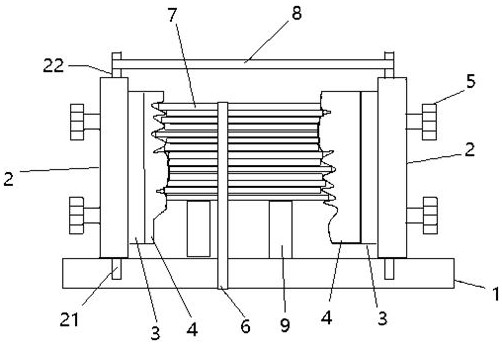

[0057] Please see attached Figure 4 , the aluminum alloy plate 7 is the blank of the car door outer plate. Since the three sides of the aluminum alloy plate 7 are straight sides and one side is an arc side, a set of protection components can be set at the three straight sides and one arc side respectively. The thickness of the aluminum alloy plate 7 is 2.5mm, the stacking quantity of the aluminum alloy plate 7 is 150, the stacking height of the aluminum alloy plate 7 is 375mm, the minimum interlayer misalignment of the aluminum alloy plate 7 is 0.2mm, and the maximum layer The difference between the staggered edges is 1mm.

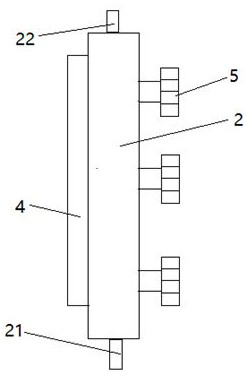

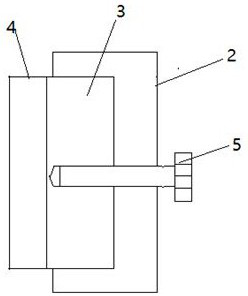

[0058] The aluminum alloy plate 7 is stacked on the backing plate 9 on the mesh tray 1, and the aluminum alloy plate 7 and the mesh tray 1 are longitudinally fastened by the fastening belt 6 to prevent the mesh tray 1 from moving up and down. Insert the positioning rods 2 of the four groups of protection components into the mesh holes of the mesh tray 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com