Toilet flushing system based on negative pressure drainage

A technology of negative pressure and water tank, which is applied in the field of sanitary ware, can solve the problems of complex structure and high cost, and achieve the effect of low cost, simple structure and saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

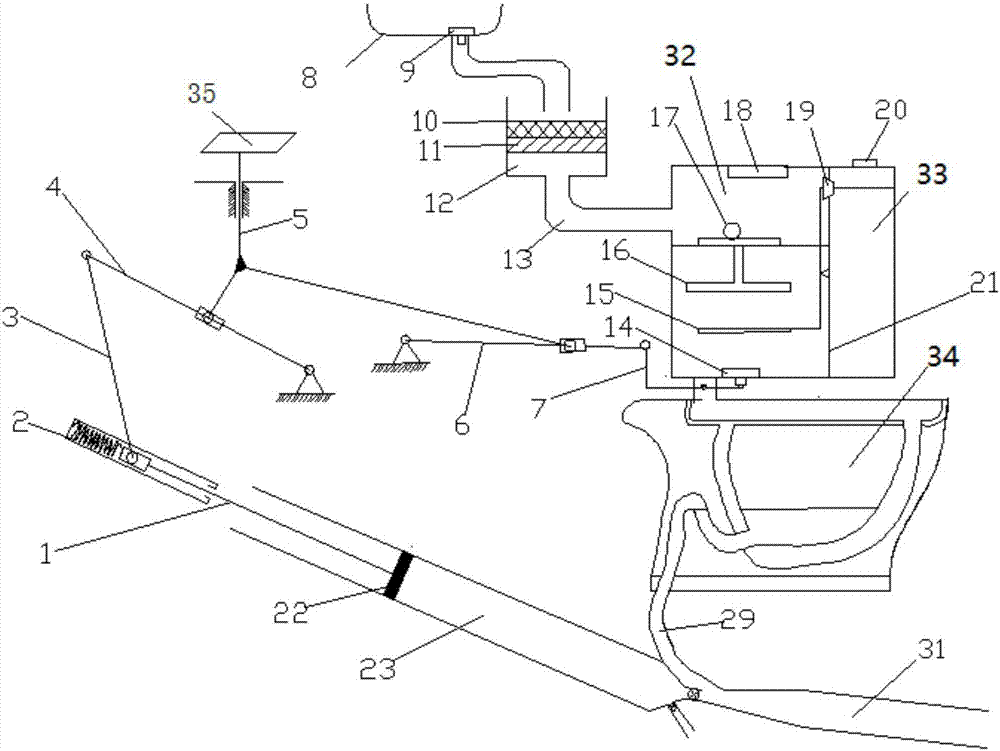

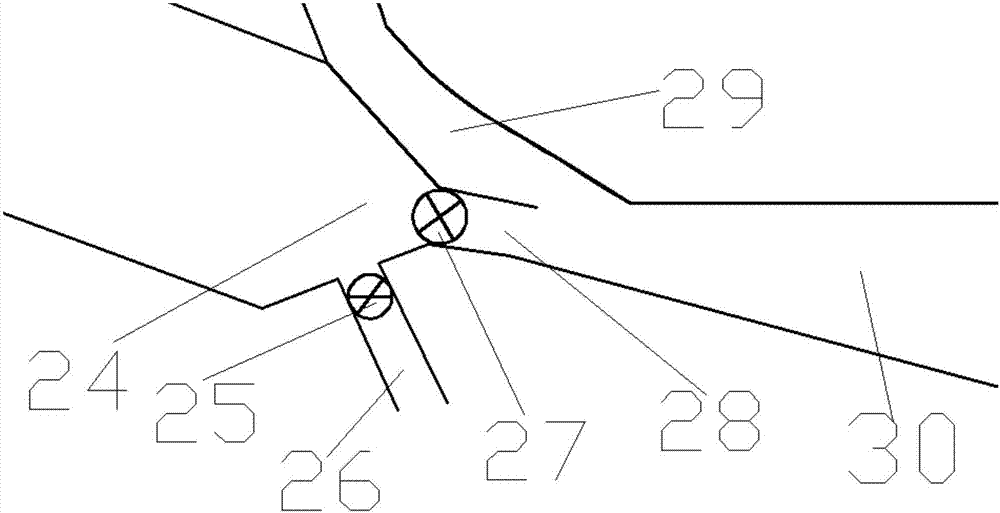

[0035] figure 1 Shown is an embodiment of the toilet flushing system based on negative pressure drainage in the present invention, and the toilet flushing system based on negative pressure drainage includes a mechanical linkage device, a water tank, a washbasin 8, a waste water treatment tank 12, a water tank inlet Water pipe 13, valve 14, buoyancy rod 15, floater 16, plug 19, partition 21, piston 22, air storage chamber 23, contraction section 24, one-way valve 25, conduit 26, one-way valve 27, throat pipe 28, Siphon elbow 29, diffusion section 30, sewage pipe 31 and toilet 34.

[0036] The water tank is divided into a water tank A32 and a water tank B33 by a partition 21. The water tank A32 is connected to the bottom of the waste water treatment tank 12 through the water tank inlet pipe 13, and the waste water treatment tank 12 is connected to the lavatory 8 through a pipeline. A strainer 9 is provided at the connection between the pool 8 and the waste water treatment tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com