Spacing optimizing method for horizontal well volume fracturing clusters

A volume fracturing and optimization method technology, applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc., can solve problems such as cluster spacing optimization, increase the volume of reservoir stimulation, and avoid excessive fracture deflection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This embodiment provides a method for optimizing the spacing between volumetric fracturing clusters in a horizontal well, which includes the following steps:

[0030] Step 1) Minimum cluster spacing optimization: when the fracture fluid pressure is a constant value, the minimum cluster spacing between two clusters of fractures is obtained within the allowable deflection angle range of the fractures of each hydraulic fracturing hole;

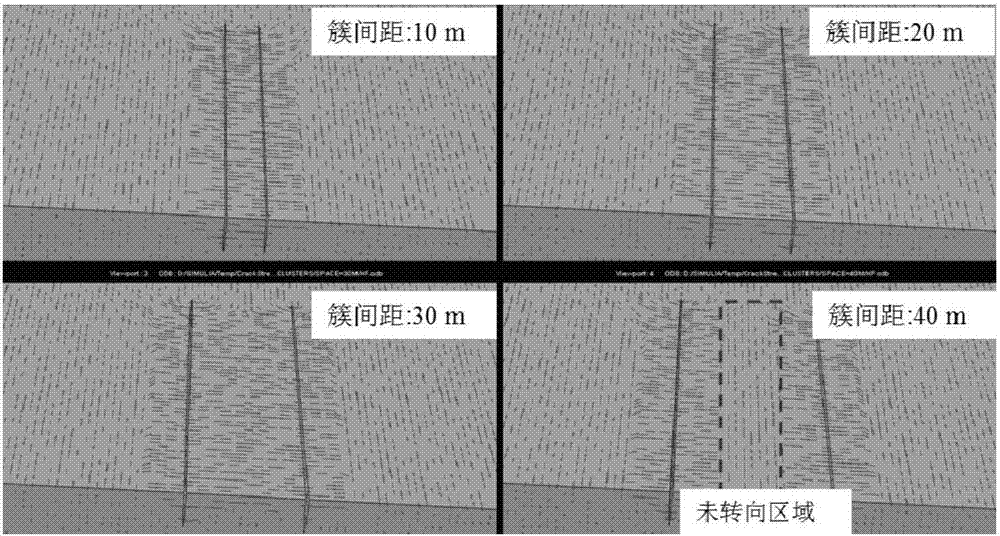

[0031] Step 2) Optimizing the maximum stimulated volume cluster spacing: when the fracture fluid pressure is a constant value, calculate the reservoir stimulated volume between two corresponding clusters of fractures at each cluster spacing, and the cluster spacing corresponding to the maximum reservoir stimulated volume is the maximum stimulated volume volume cluster spacing;

[0032] Step 3) Compare the minimum cluster spacing and the maximum cluster spacing of the modified volume under the same fracture fluid pressure, and the larger of...

Embodiment 2

[0035] On the basis of Embodiment 1, this embodiment provides a method for optimizing the cluster spacing of horizontal well volume fracturing. The volume of the reservoir stimulation is calculated by calculating the steering angle of the intermediate principal stress between two clusters of fractures during the fracturing process. When the steering angle of the intermediate principal stress between two clusters of fractures exceeds a certain value, this area is the area to be stimulated, and the corresponding volume is the volume of reservoir stimulation.

[0036] The steering angle calculation process of the intermediate principal stress is as follows:

[0037] Divide the volume between two clusters of fractures into m equal parts, the stress tensor on each equal part The eigenvalues and eigenvectors of the stress tensor S on each equalization are obtained separately, and the eigenvector n corresponding to the intermediate eigenvalue is the direction of the intermediate p...

Embodiment 4

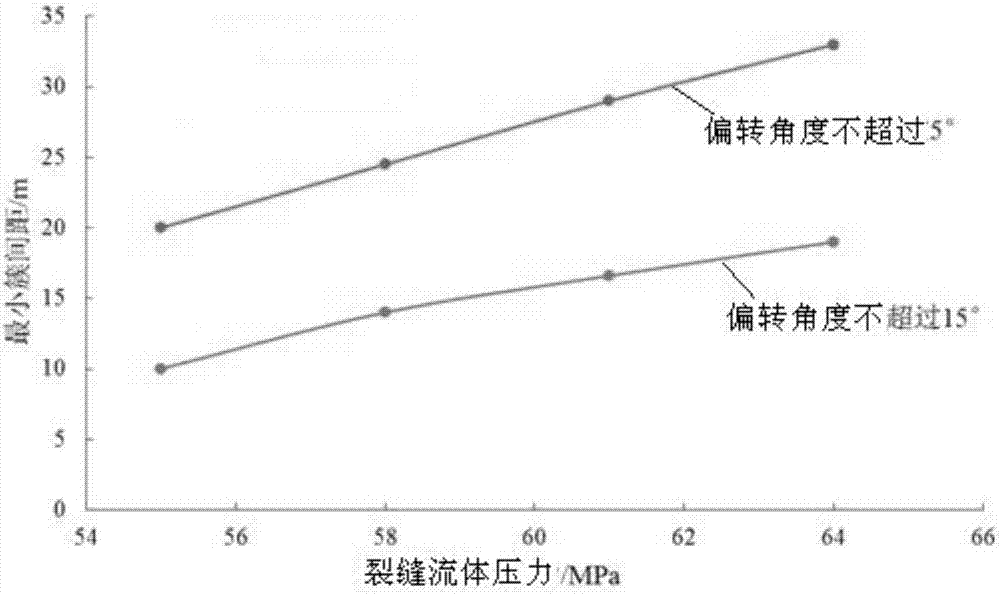

[0043] On the basis of Example 3, this example uses the in-situ stress parameters and rock mechanics parameters of tight sandstone reservoirs in Changqing Oilfield to optimize the minimum cluster spacing and the maximum stimulated volume cluster spacing to obtain a reasonable optimal cluster spacing. In the following calculation example, the calculation and analysis are carried out for three different fracture fluid conditions of 58MPa, 61MPa and 64MPa. In-situ stress parameters and rock mechanics parameters are shown in Table 1.

[0044] Table 1 In-situ stress parameters and rock mechanics parameters

[0045]

[0046] 1) Minimum cluster spacing optimization:

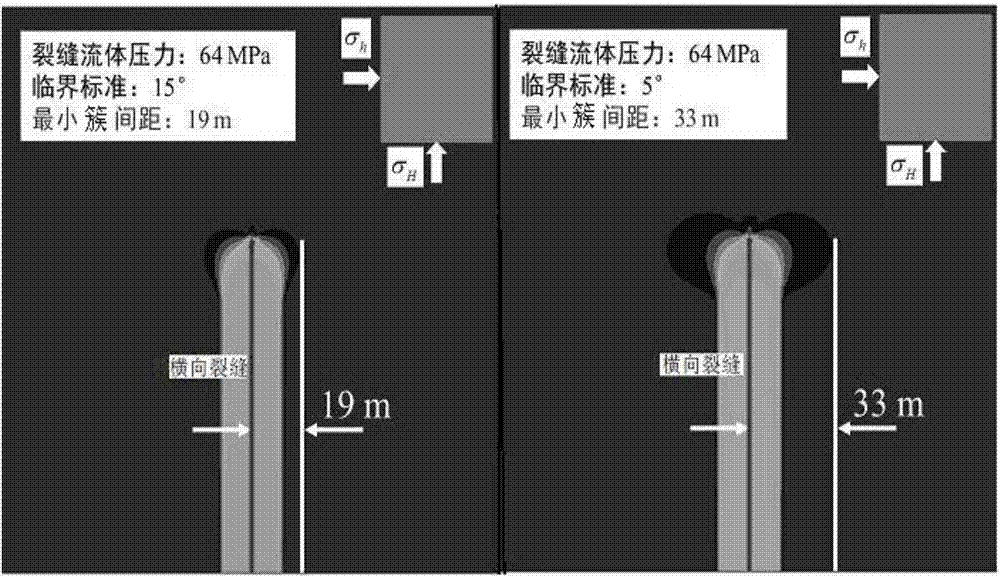

[0047] The allowable value of the fracture deflection angle is different, and the result of the minimum cluster spacing will also change. figure 1 The deflection near the fracture is given when the fracture fluid pressure is 64MPa. The middle gray area represents that the deflection angle of the intermediate princi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com