Battery testing device

A battery testing and equipment technology, applied in impact testing, machine/structural component testing, measuring electricity, etc., can solve the problems of difficulty in fully simulating battery state and environment, uncertain pressure, and high testing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

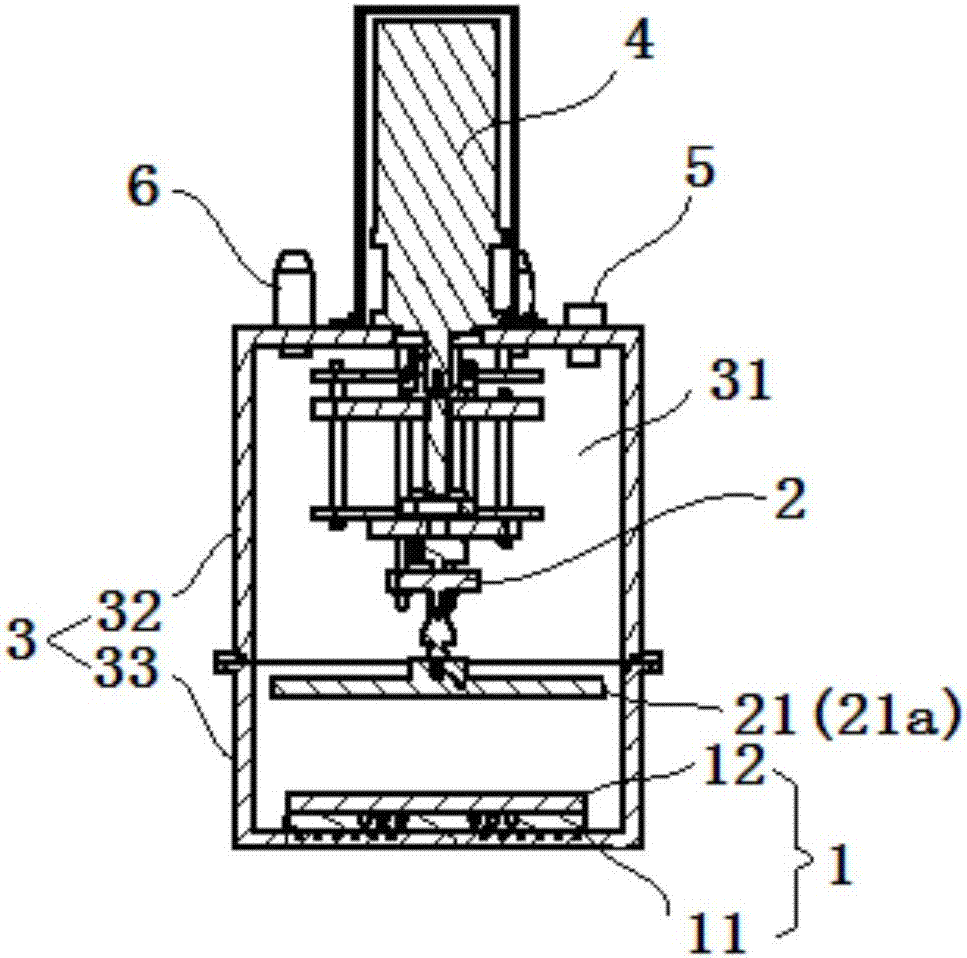

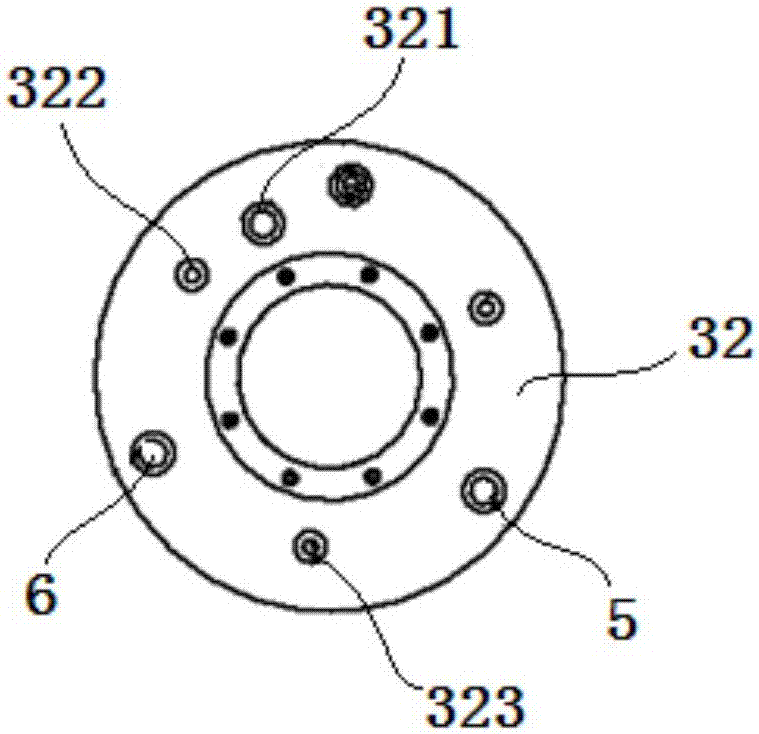

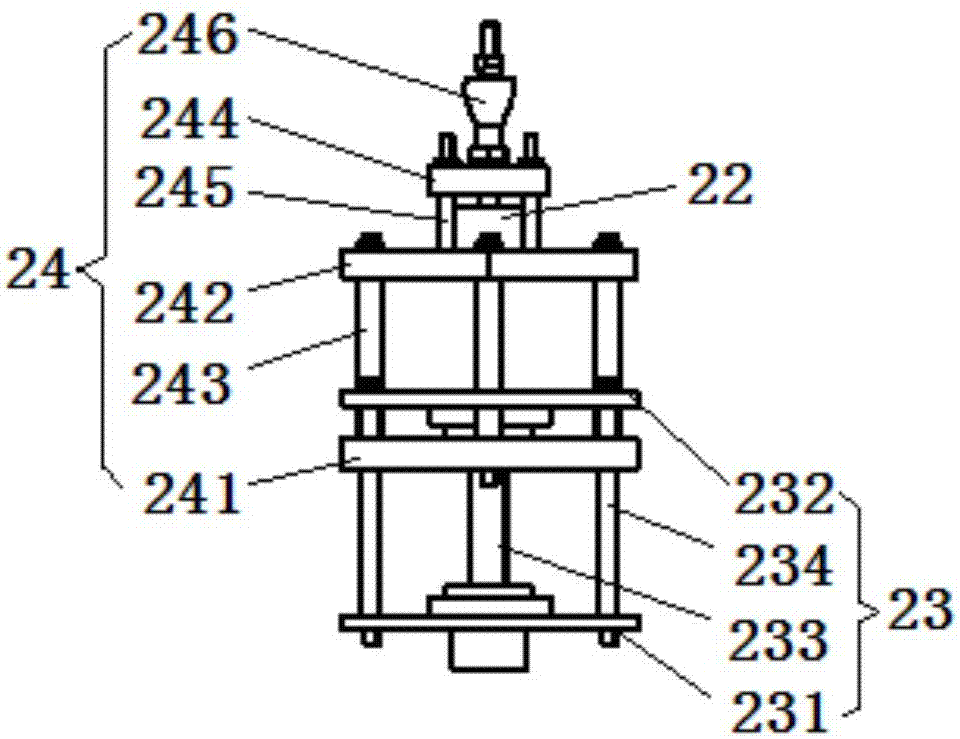

[0043] refer to Figure 1 to Figure 6b , a battery testing device according to a preferred embodiment of the present invention includes a supporting heating mechanism 1 and a pressure applying mechanism 2 .

[0044] Wherein, the battery under test (not shown) can be supported on the supporting heating mechanism 1 and heated by the supporting heating mechanism 1 so as to make the battery under test have a required testing temperature. By controlling the heating element (such as the electric heating plate 11 described below), the tested battery can have different temperatures.

[0045] The pressing mechanism 2 has a pressing element 21 (such as a pressure push p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap