Touch display panel and display device

A technology for touching display panels and substrates, used in instruments, computing, electrical and digital data processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

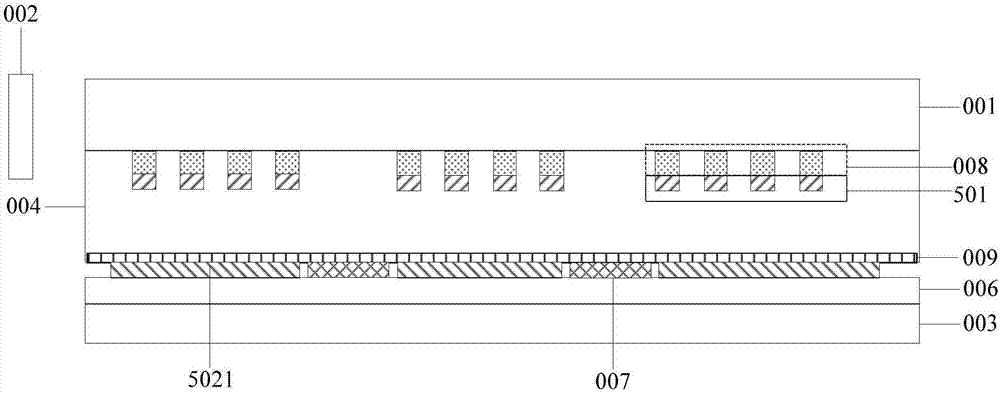

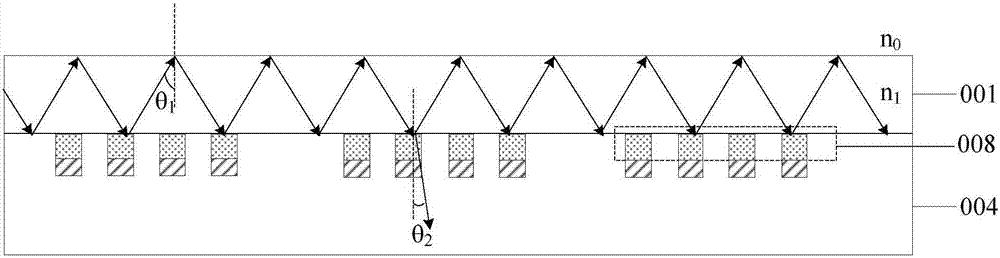

[0041] The touch display panel and the display device provided by Embodiment 1 of the present invention, such as Figure 1a As shown, it includes: a waveguide plate 001 and a lower substrate 003 facing each other, a liquid crystal layer 004 and an electrode structure 005 disposed between the waveguide plate 001 and the lower substrate 003, and a reflector disposed on the side of the lower substrate 003 facing the liquid crystal layer 004 layer 006, and a plurality of photosensitive units 007 disposed on the side of the lower substrate 003 facing the liquid crystal layer 004; wherein,

[0042] The electrode structure 005 is used to control the refractive index of the liquid crystal molecules in the liquid crystal layer 004 so that the light is emitted from the lower surface of the waveguide plate 001 close to the liquid crystal layer 004 or totally reflected inside the waveguide plate 001 .

[0043] Moreover, in specific implementation, in order to realize color display, in the ...

Embodiment 2

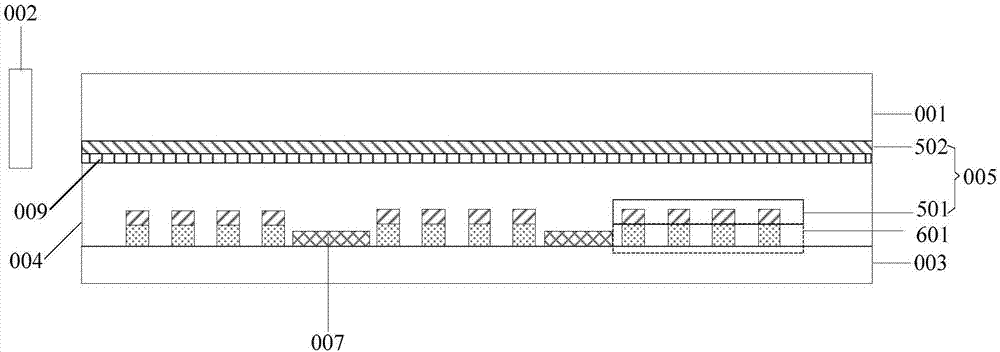

[0067] Since the touch display panel and the display device provided in the second embodiment of the present invention are similar in structure to the touch display panel and the display device provided in the first embodiment of the present invention, only the touch display panel and the display device provided in the second embodiment of the present invention are the same as those of the present invention. The differences between the touch display panel and the display device provided in Embodiment 1 will be introduced, and the overlapping parts will not be repeated.

[0068] Specifically, different from the reflective layer and electrode structure in the touch display panel and display device provided in Embodiment 1 of the present invention and the specific implementation manners for realizing color display, in the touch display panel and display device provided in Embodiment 2 of the present invention, Such as Figure 1b As shown, the reflective layer 006 may specifically...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com