Integral graph algorithm-based fabric flaw detection method

A defect detection and integral image technology, which is applied in computing, image enhancement, image analysis, etc., can solve the problems that the fabric defect detection system relies on human eye observation, does not meet the real-time requirements of industrial production, and has poor effects on complex textured fabrics. The effect of removing the interference of illumination changes, high accuracy, and accurately segmenting defective areas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

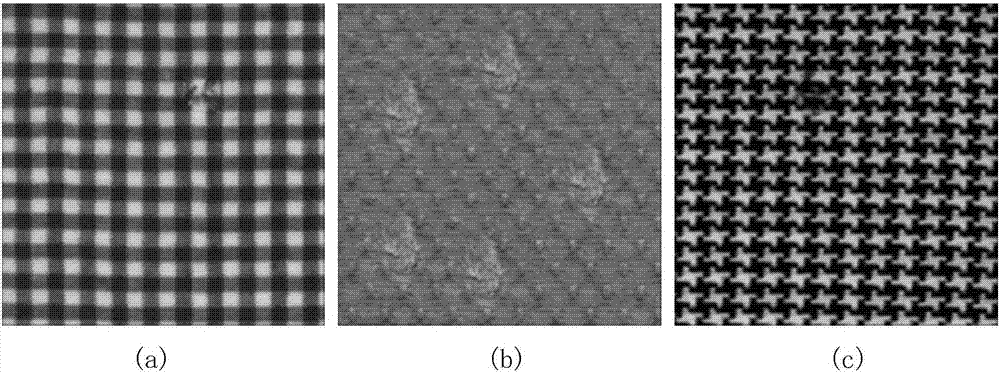

Examples

specific Embodiment approach

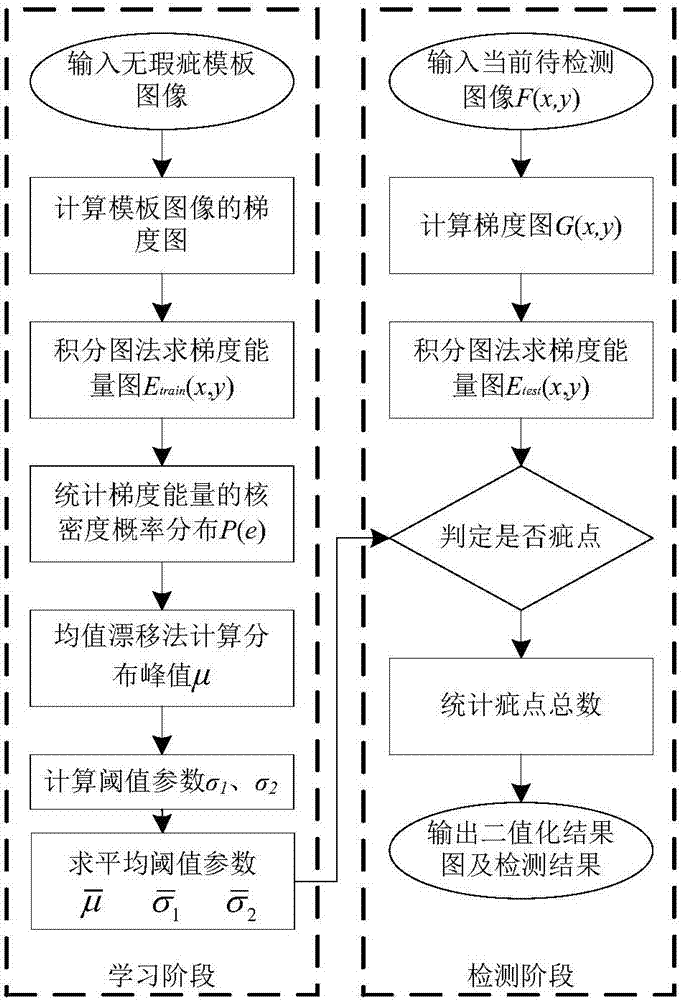

[0041] Such as figure 1 As shown, the present invention first conducts image learning on the flawless template, counts its gradient energy feature distribution, and the obtained feature distribution is asymmetrical, uses a kernel function to fit the feature distribution, combines the mean shift method to extract the peak of the distribution, and then uses the peak adaptive Calculate the threshold parameter, which is used to distinguish subsequent defects; then, the image to be detected is calculated by the integral graph algorithm to obtain the gradient energy of the detection window where each pixel is located, and combined with the threshold parameter, it is determined whether the current pixel is Defects, by counting the total number of defects in the entire image to determine whether the current image is a defective fabric, the specific implementation is as follows:

[0042] 1. Gradient energy feature extraction based on integral graph:

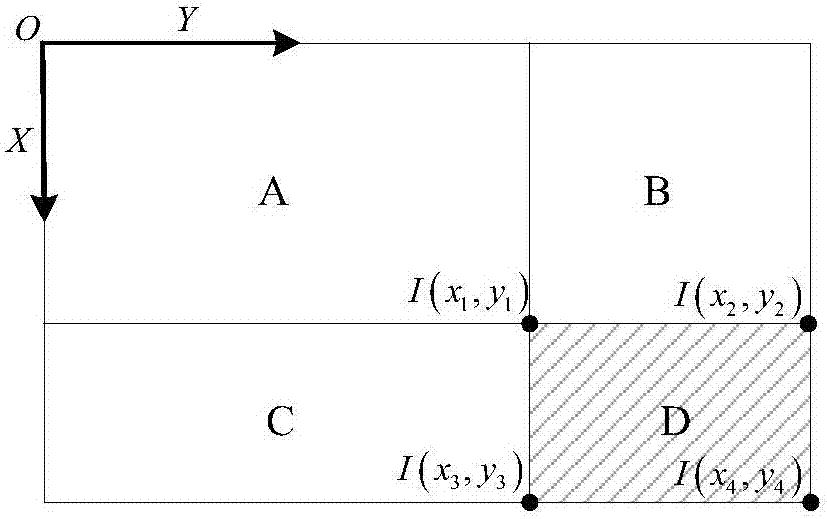

[0043] Generally speaking, the text...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com