Polishing vacuum absorption device capable of improving absorption efficiency

A technology of vacuum adsorption and high efficiency, which is applied in the direction of grinding feed movement, grinding workpiece support, grinding machine tool parts, etc., can solve the problems of increasing production cost of enterprises, reducing negative pressure performance, and limited actual effect, and achieves saving Improved cost, improved adsorption performance, and enhanced adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

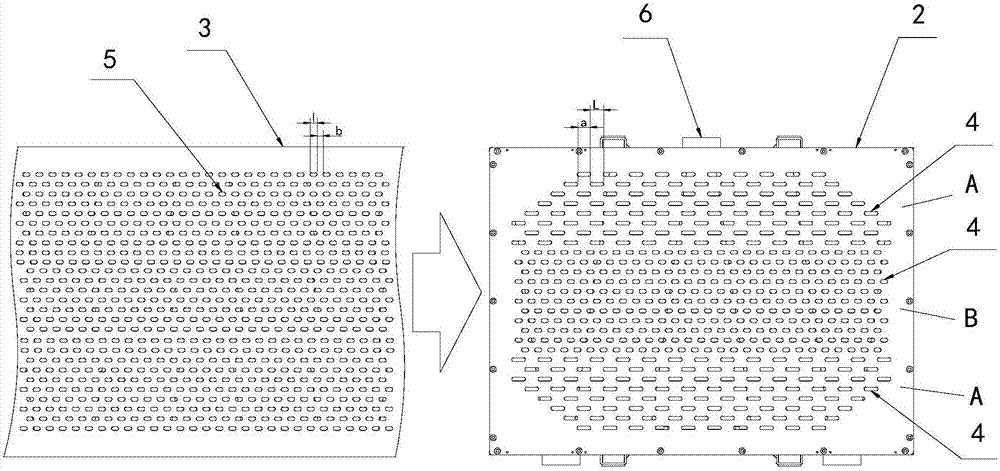

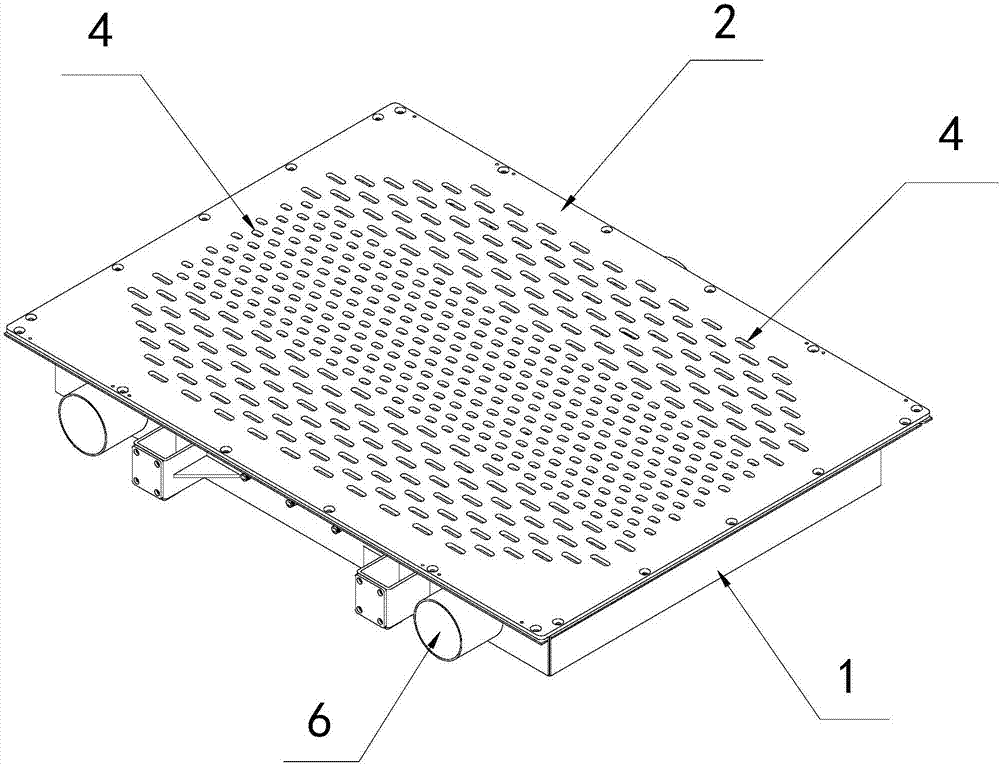

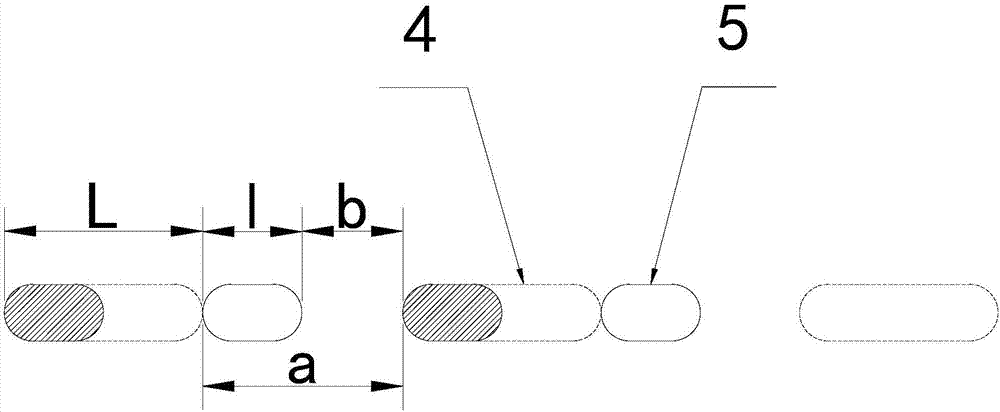

[0024] Embodiment: Below in conjunction with Figure 1~3 The structural principle of the present invention is described in detail, and this embodiment exemplifies a special case of the present invention.

[0025] Such as figure 1 and figure 2 The shown grinding vacuum adsorption device that can enhance the adsorption efficiency has a negative pressure chamber 1, an adsorption cover 2 fixed on the upper part of the negative pressure chamber 1, and an adsorption cover 2 above the adsorption cover 2 for transporting workpieces. The transmission belt 3, the adsorption cover plate 2 is provided with several rows of adsorption holes 4 along the moving direction of the transmission belt 3, the adsorption holes 4 in each row are evenly spaced, and the transmission belt 3 corresponds to the rows below it. The adsorption holes are provided with several rows of openings 5, and the openings 5 in each row are also evenly spaced. The negative pressure chamber 1 is provided with a sucti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com