Pressurizing shower head

A shower and negative pressure technology, applied in the field of sanitary ware, can solve problems such as waste of water resources and affect the user experience of products, achieve the effects of reducing production costs, avoiding waste of water resources, and improving market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

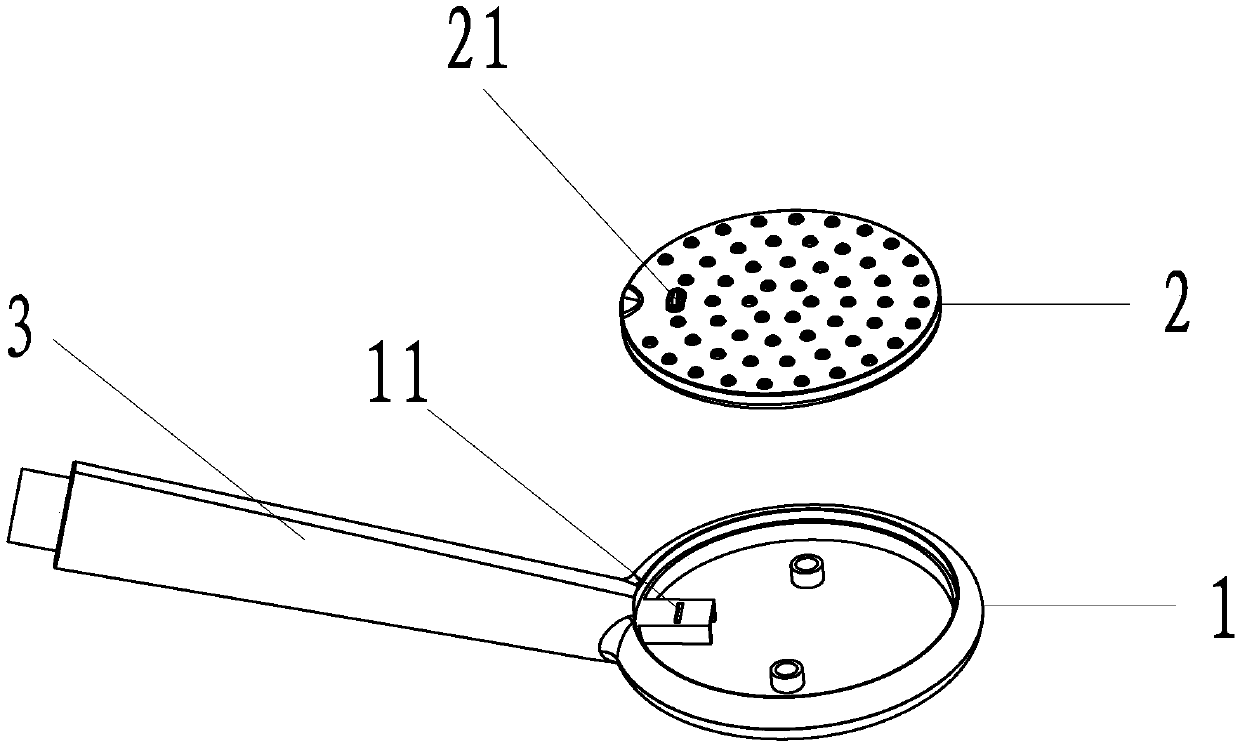

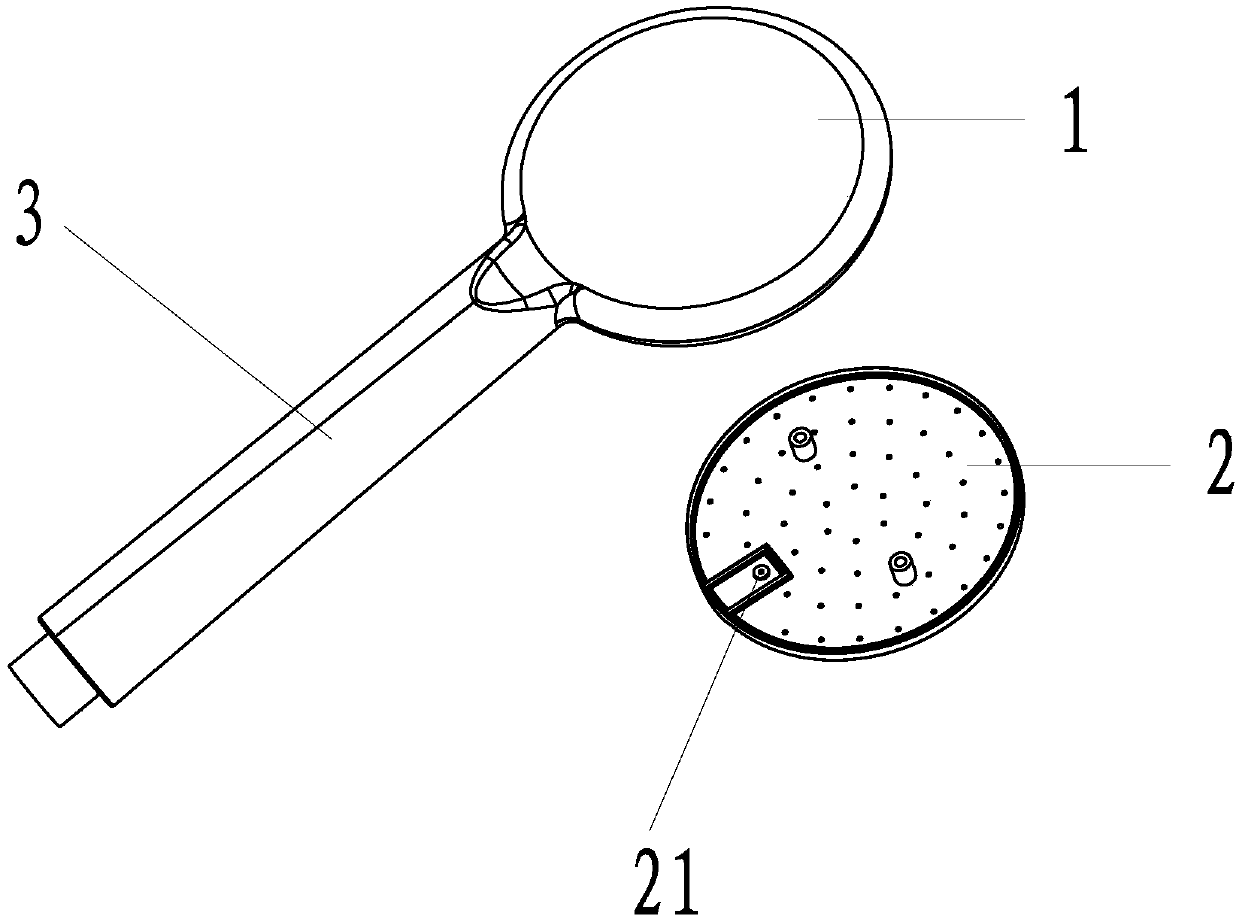

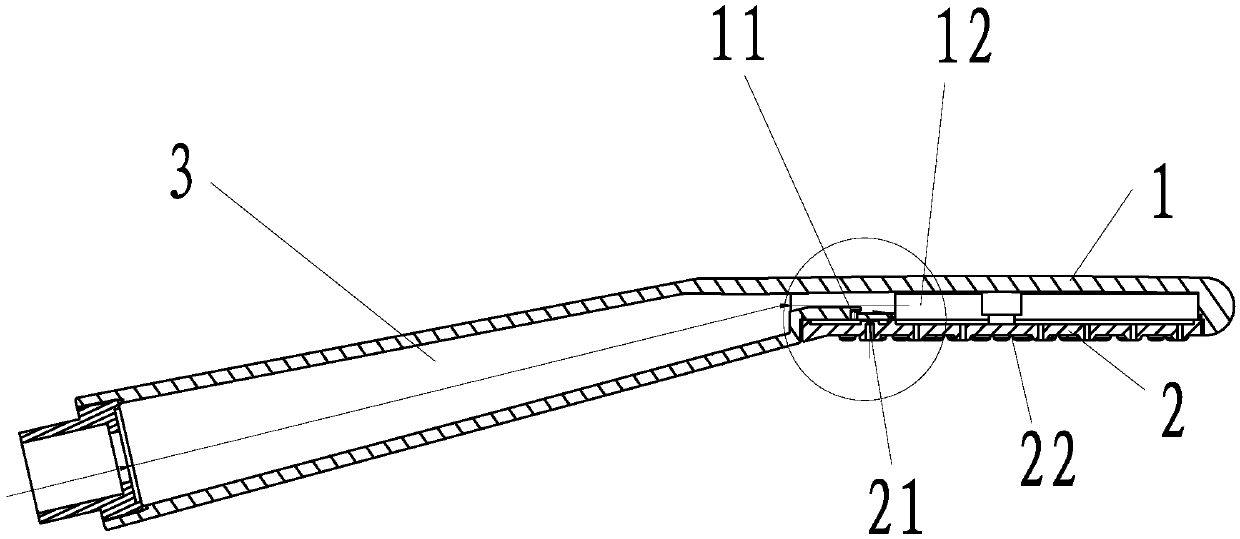

[0022] A pressurized shower, refer to Figures 1 to 5 , comprising an upper cover 1, a lower cover 2, and a handle 3, the upper cover 1 and the handle 3 are integrally formed; the upper cover 1 is fixedly connected to the lower cover 2; the lower cover 2 is close to the The handle 3 is provided with an air inlet 21 along the water outlet direction; the upper cover 1 is provided with a water barrier facing the air inlet 21, and there is a water barrier between the water barrier and the lower cover 2. An air intake chamber 23, the air intake chamber 23 communicates with the air intake hole 21; there is also a negative pressure cavity 24 between the upper cover 1 and the lower cover 2, and the negative pressure cavity 24 communicates with the air intake Cavity 23; the upper cover 1 is provided with an air inlet groove 11 along the water outlet di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com