Method for synthesizing aluminum-rich * MRE zeolite molecular sieve in one step by using organic template agent

A technology of zeolite molecular sieve and organic template agent, which is applied in the direction of crystalline aluminosilicate zeolite, molecular sieve and alkali exchange compound, chemical instrument and method, etc., can solve the problem of increasing the cost of synthesizing ZSM-48 zeolite molecular sieve, hexamethylene bromide The high cost of diammonium and the high price of crown ether have achieved the effect of easy-to-obtain structure, excellent guiding performance, and low silicon-aluminum ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] First, add 1.73g of tetraethoxysilane to 4g of diethyldimethylammonium hydroxide aqueous solution and 3.6g of deionized water, then add 0.113g of aluminum isopropoxide, and finally add 0.05g of sodium chloride and stir After 12 hours, add the reaction raw materials into a polytetrafluoroethylene stainless steel reaction kettle, and crystallize at 180°C for 48 hours to complete the crystallization. After the reaction is completed, the reaction product is washed with deionized water and dried at 80°C for 12 hours to obtain Al-rich* MRE zeolite molecular sieve.

[0029] The molar ratio of the reaction raw materials is as follows: SiO 2 :Al 2 o 3 : Na 2 O: R: H 2 O=30:1:1.5:30:1200.

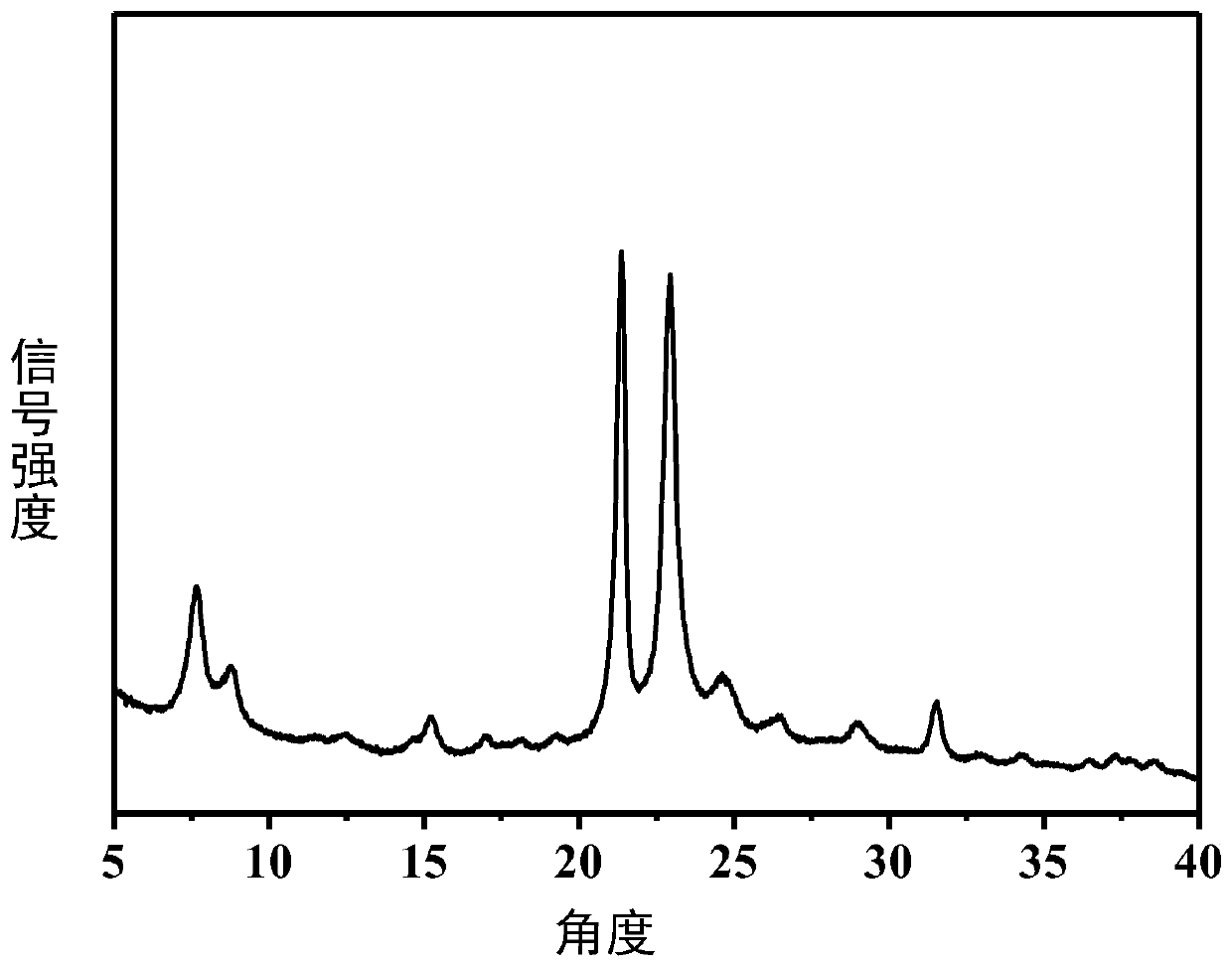

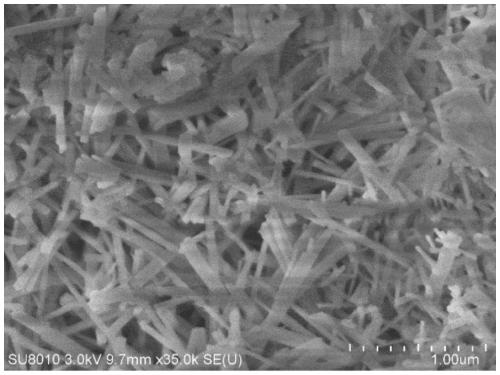

[0030] Its structure is *MRE zeolite molecular sieve ( figure 1 ), and it can be seen from the scanning electron microscope that the length of the synthesized product is 1 μm, and the width is about 100 nm in a one-dimensional rod-like structure ( figure 2 ). The ICP assay results of ...

Embodiment 2

[0032] The addition sequence and stirring time of gel preparation are the same as in Example 1, and the amount of each material is 1.73g of tetraethoxysilane, 4g of diethyldimethylammonium hydroxide aqueous solution, 3.6g of deionized water, and 0.05g of sodium chloride , 0.057g of aluminum isopropoxide, crystallized at 180°C for 48h, and then completely crystallized. After the reaction was completed, the reaction product was washed with deionized water and dried at 80°C for 12h to obtain an aluminum-rich *MRE zeolite molecular sieve.

[0033] The molar ratio of the reaction raw materials is as follows: SiO 2 :Al 2 o 3 : Na 2 O: R: H 2 O=30:0.5:1.5:30:1500.

Embodiment 3

[0035] The addition sequence and stirring time of gel preparation are the same as Example 1, and the amount of each material is 1.73g of tetraethoxysilane, 4g of diethyldimethylammonium hydroxide aqueous solution, 3.6g of deionized water, and 0.05g of sodium chloride , 0.17g of aluminum isopropoxide, crystallized at 180°C for 48h to complete crystallization, after the reaction was completed, the reaction product was washed with deionized water and dried at 80°C for 12h to obtain an aluminum-rich *MRE zeolite molecular sieve.

[0036] The molar ratio of the reaction raw materials is as follows: SiO 2 :Al 2 o 3 : Na 2 O: R: H 2 O=30:1.5:1.5:30:1500.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com