Fermentation tank

A fermentation tank and fermentation liquid technology, applied in the field of fermentation tanks, can solve the problems of insufficient fermentation, difficult cleaning of fermentation tanks, poor mixing effect of materials, etc., and achieve the effects of sufficient mixing of materials, easy cleaning and convenient cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

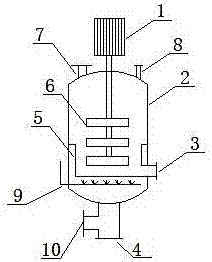

[0009] attached figure 1 A fermenter of the present invention is shown, which has a stirring motor 1, a fermenter body 2, a waste discharge pipe 3, a fermentation liquid outlet pipe 4, a filter 5, a stirring paddle 6, a feed pipe 7, a vent pipe 8, an air Pipe 9, flushing pipe 10, stirring motor 1 is installed on the upper part of the fermentation tank body 2, and the stirring motor 1 is connected to the stirring paddle 6 through the stirring shaft. Hole welding vent pipe 8, fermentation tank body 2 bottom center opening welding fermentation liquid outlet pipe 4, fermentation tank body 2 middle and lower inner side welding filter 5, filter 5 bottom right side opening welding waste discharge pipe 3, fermentation liquid One side of the outlet pipe 4 is perforated and welded with a flushing pipe 10, and an air pipe 9 is perforated and welded between the filter 5 and the fermentation tank body 2, and the outer surface of the air pipe 9 is evenly distributed with nozzles.

[0010] ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap