Roller brush adjusting structure

A technology for adjusting the structure and rolling brushes, applied in road cleaning, construction, cleaning methods, etc., can solve the problems of uneven roads, damaged rolling brushes, inconsistent rolling brush wear, etc., to achieve simple structure, avoid different degrees of wear, and use handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

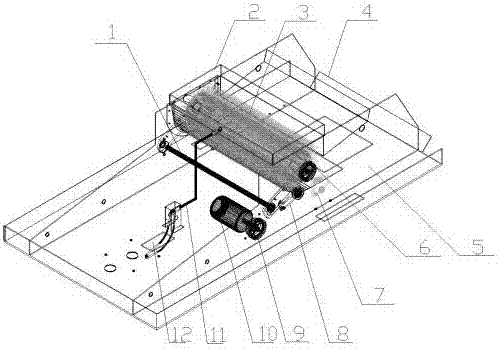

[0015] The present invention will be described below in conjunction with the accompanying drawings. Such as figure 1 as shown, figure 1 It is a structural schematic diagram of the present invention.

[0016] Comprising vehicle frame bottom plate and rolling brush 3, the both sides of vehicle frame bottom plate are fixedly provided with side plate 5, and the rear of rolling brush 3 is provided with dustbin 4, and rolling brush 3 is installed in the rolling brush box, and the bristle of rolling brush 3 is from rolling A number of through holes on the brush box protrude out and touch the ground, wherein, the front of the roller brush 3 is provided with a fixed seat 12, and the upper shaft of the fixed seat 12 is connected with a rubber pull rod 11, and the end of the rubber railing 11 is connected with the roller brush box , the side plate 5 is provided with a connecting plate 1 fixed shaft, one side of the roller brush 3 is provided with a lifting device / 7, the two ends of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com