Heading machine loaded atomizing pump

A roadheader and spray pump technology, applied in the field of water pumps, can solve problems such as poor atomization effect, inability to use, and too much waste water in the spray device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

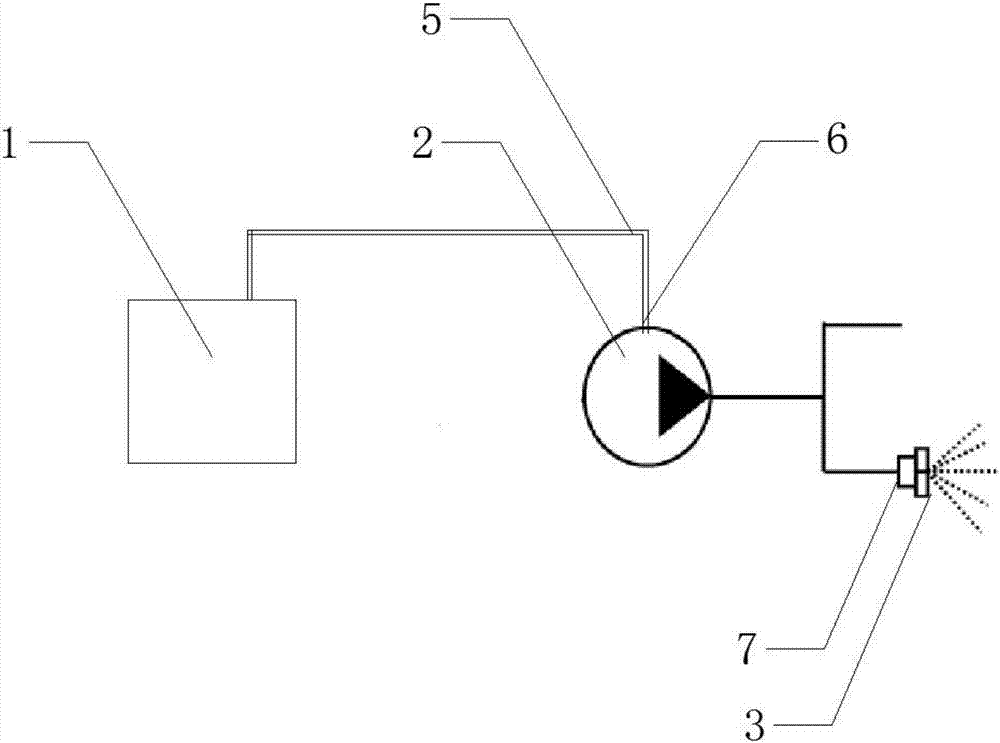

[0016] Such as figure 1 As shown, a roadheader airborne spray power system includes a roadheader 1, a water pump 2 and an atomizer 3, the hydraulic system 5 of the roadheader 1 is connected to the high-pressure oil inlet 6 of the water pump 2, and the roadheader The hydraulic system 5 of 1 drives the high-pressure pump to work through the reciprocating motion of the plunger, converts the low-pressure water supplied to the high-pressure pump into high-pressure water, and then passes through the matching atomizer 3, which is atomized by the atomizer 3 into a high-speed atomized flow and sprayed to the dust. source to achieve effective control of dust.

[0017] Preferably, the outlet of the water pump 2 is connected to the atomizer 3, and the atomizer 3 is connected to a plurality of spray heads.

[0018] The water pump uses the piston of the hydraulic oil cylinder to push the piston of the high-pressure water pump to reciprocate, so high water pressure can be generated without ...

Embodiment 2

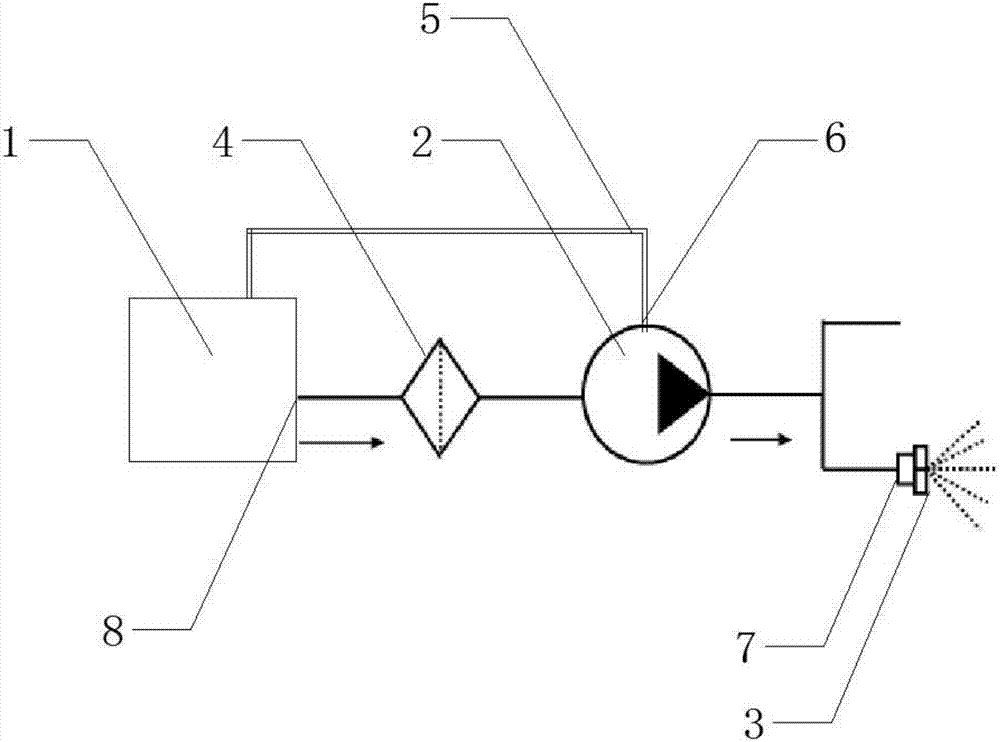

[0020] Such as figure 2 As shown, on the basis of Embodiment 1, the water suction port 7 of the water pump 2 is connected to the cooling water outlet 8 of the roadheader 1; the water pump 2 adopts positive pressure water supply and is directly installed at a reasonable position on the body of the roadheader 1 The water pump 2 supplies water from the cooling outlet of the roadheader 1; the cooling water outlet 8 of the roadheader 1 is provided with a filter 4.

[0021] The water consumption of this device is correspondingly reduced, and the water inlet filter equipped with the spray system can ensure the filtration of spray water and prevent impurities from entering the high-pressure pump and spray system; compared with ordinary water pumps, the output water pressure of this device can be adjusted by a pressure regulating valve or It is directly adjusted by the input power of the hydraulic system. The small and compact appearance of the water pump can be easily installed on an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com