Airflow horizontal movement type drying room with dehumidification free of influencing airflow circulation

An air circulation and translational technology, applied in the direction of drying, drying machine, drying gas arrangement, etc., can solve the problems of drying room construction, inconvenient use, complex dehumidification system, slow drying of materials, etc., and achieve excellent baking effect , The air circulation channel is spacious, and the effect of drying is uniform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

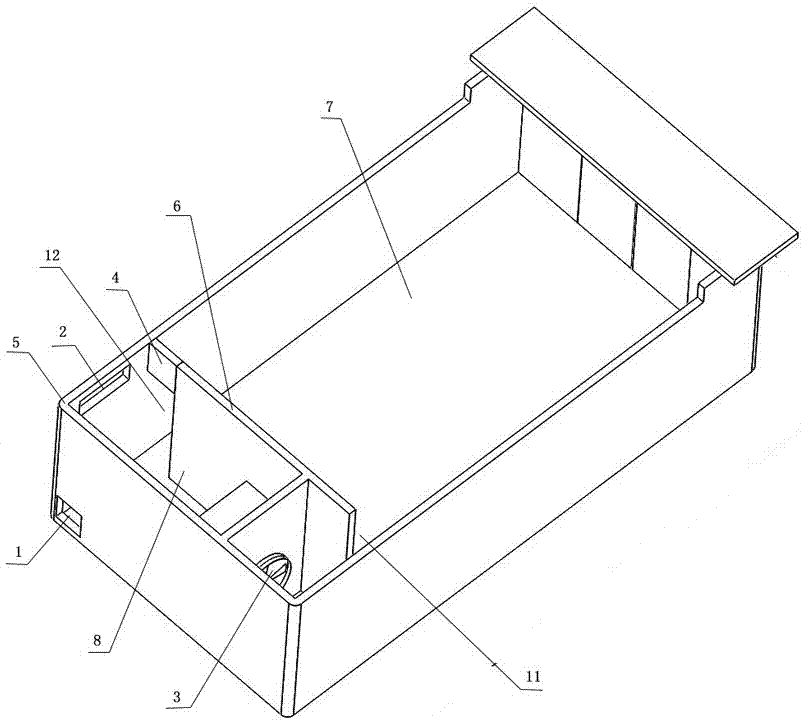

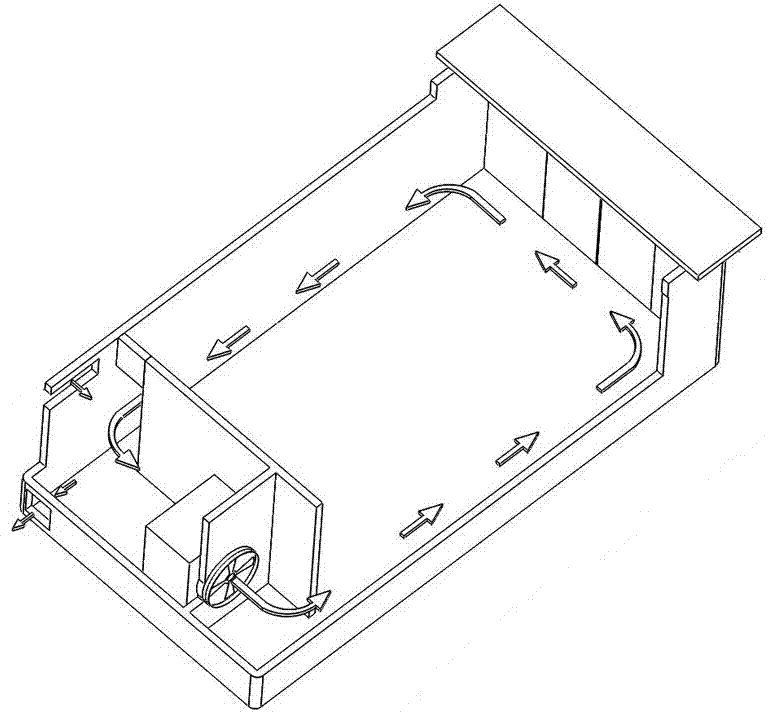

[0023] Such as Figure 1-2 As shown, the present invention discloses an air flow translational single circulation drying room in which the return air blocking area 4 is arranged at the top of the return air outlet 12. The left and right sides of the partition wall 6 between the heating chamber 8 and the material chamber 7 are respectively provided with heating chamber 8 The air inlet 11 for supplying air to the material chamber 7 and the return air outlet 12 for returning air from the material chamber 7 to the heating chamber 8 , the return air blocking area 4 is arranged on the top of the return air outlet 12 . The drying room is provided with an air intake facility and a dehumidification facility. The air intake facility is connected to the air inlet 2 outside the drying room or an air intake fan or a combination of the two. The dehumidification facility is a External dehumidification port 1 or dehumidification fan or a combination of the two, the air inlet 2 is set on the s...

Embodiment 2

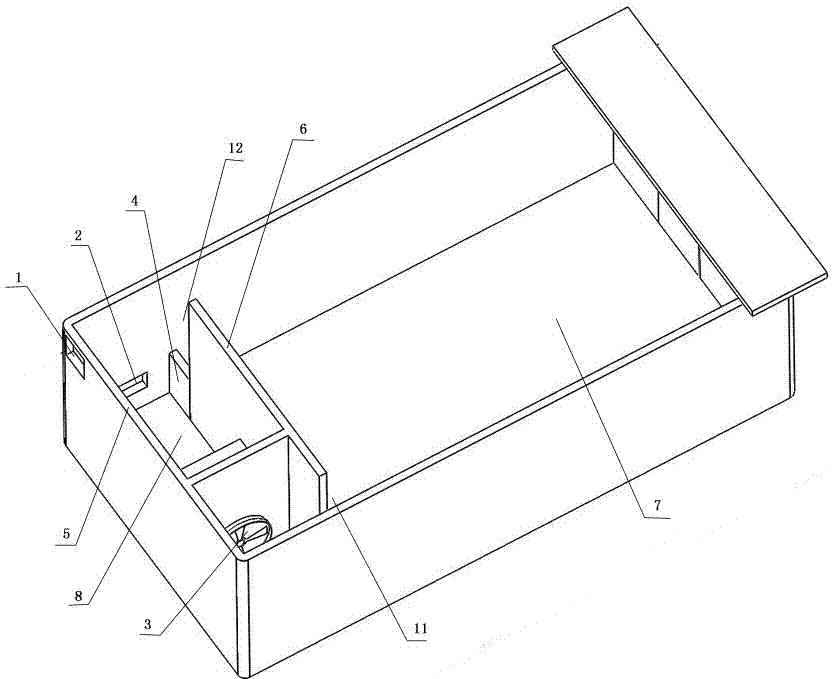

[0029] Such as image 3 As shown, the present invention discloses an airflow translational single-circulation drying room in which the return air blocking area 4 is arranged in the middle of the return air outlet 12. The left and right sides of the partition wall 6 between the heating chamber 8 and the material chamber 7 are respectively provided with a heating chamber 8 The air inlet 11 that supplies air to the material chamber 7 and the air return port 12 that returns air from the material chamber 7 to the heating chamber 8, the return air blocking area 4 is located in the middle of the return air port 12, and the return air port 12 is located at the end of the return air blocking area 4 Up and down sides. The drying room is provided with an air intake facility and a dehumidification facility. The air intake facility is connected to the air inlet 2 outside the drying room or an air intake fan or a combination of the two. The dehumidification facility is a External dehumidif...

Embodiment 3

[0032] Such as Figure 4 As shown, the present invention discloses an air flow translational single-circulation drying room in which the return air blocking area 4 is arranged at the lower end of the return air outlet 12. The left and right sides of the partition wall 6 between the heating chamber 8 and the material chamber 7 are respectively provided with a heating chamber 8 The air inlet 11 for supplying air to the material chamber 7 and the air return port 12 for returning air from the material chamber 7 to the heating chamber 8, the air return blocking area 4 is arranged at the bottom of the air return port 12 .

[0033] The drying room is provided with an air intake facility and a dehumidification facility. The air intake facility is connected to the air inlet 2 outside the drying room or an air intake fan or a combination of the two. The dehumidification facility is a External dehumidification port 1 or dehumidification fan or a combination of the two, the air inlet 2 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com