Low attenuation single-mode optical fiber and preparation method thereof

A single-mode optical fiber, low attenuation technology, applied in the direction of cladding optical fiber, glass manufacturing equipment, glass fiber products, etc., can solve the problems such as no mention of chlorine doping process parameters, etc., to reduce Rayleigh scattering loss and reduce structural relaxation Time, the effect of improving the uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

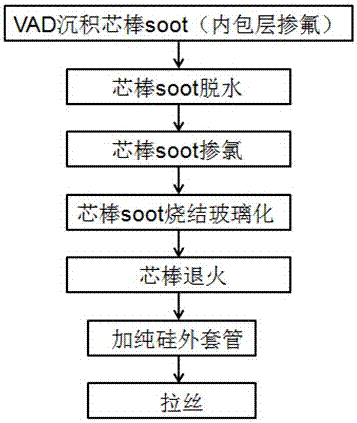

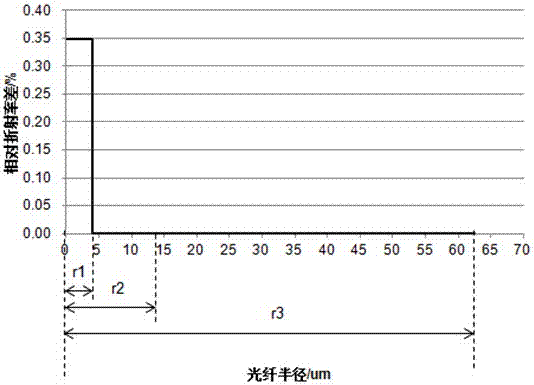

[0048] The present invention prepares the method for low-attenuation preform rod and optical fiber, as figure 1 As shown, the core rod soot is deposited by the VAD process, GeCl4 is introduced into the core layer deposition process to do germanium, and the fluorine-containing raw material (one or more of CF4, SF6, C2F6, SiF4) is introduced into the inner cladding layer deposition process as The dopant is doped with fluorine to form a core rod soot in which the core layer is doped with germanium and the inner cladding layer is doped with fluorine. Put the mandrel soot into the sintering furnace for dehydration. After the dehydration is completed, feed a certain amount of chlorine-containing raw material (Cl2 and / or SiCl4) as a dopant to do chlorine doping, and then perform sintering, densification and annealing to obtain the doped core layer. Germanium and chlorine, inner cladding doped with fluorine and chlorine glass core rod, wherein the contribution of negative refractive i...

Embodiment 2

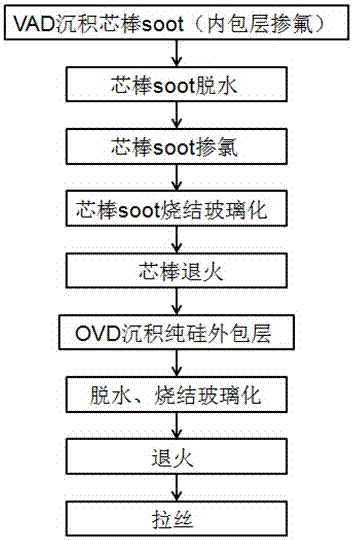

[0054] The present invention prepares the method for low-attenuation preform rod and optical fiber, as figure 2 As shown, the core rod soot is deposited by the VAD process, GeCl4 is introduced into the core layer deposition process to do germanium, and the fluorine-containing raw material (one or more of CF4, SF6, C2F6, SiF4) is introduced into the inner cladding layer deposition process as The dopant is doped with fluorine to form a core rod soot in which the core layer is doped with germanium and the inner cladding layer is doped with fluorine. Put the mandrel soot into a sintering furnace for dehydration. After the dehydration is completed, a certain amount of chlorine-containing raw material (Cl2 and / or SiCl4) is introduced as a dopant for chlorine doping, and then sintered and densified to obtain a core layer doped with germanium and Chlorine, inner cladding glass core rod doped with fluorine and chlorine, wherein the negative refractive index contribution of the inner c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com