Shipping agency, agency used to handle items, and shipping method

A technology for items and processing stations, applied in the direction of conveyor items, transportation and packaging, conveyors, etc., can solve problems such as low wear resistance, substrate damage, and limited functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

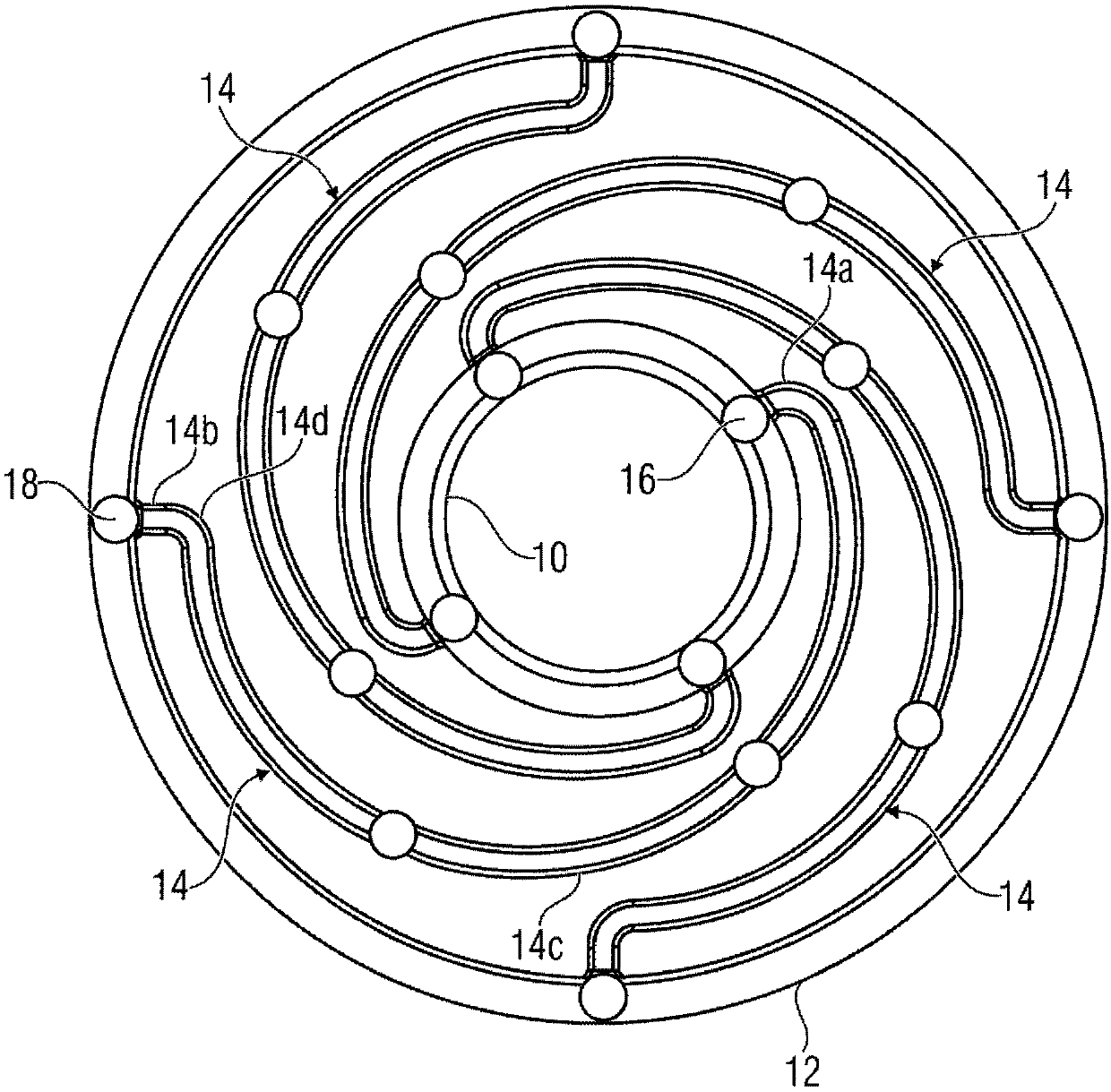

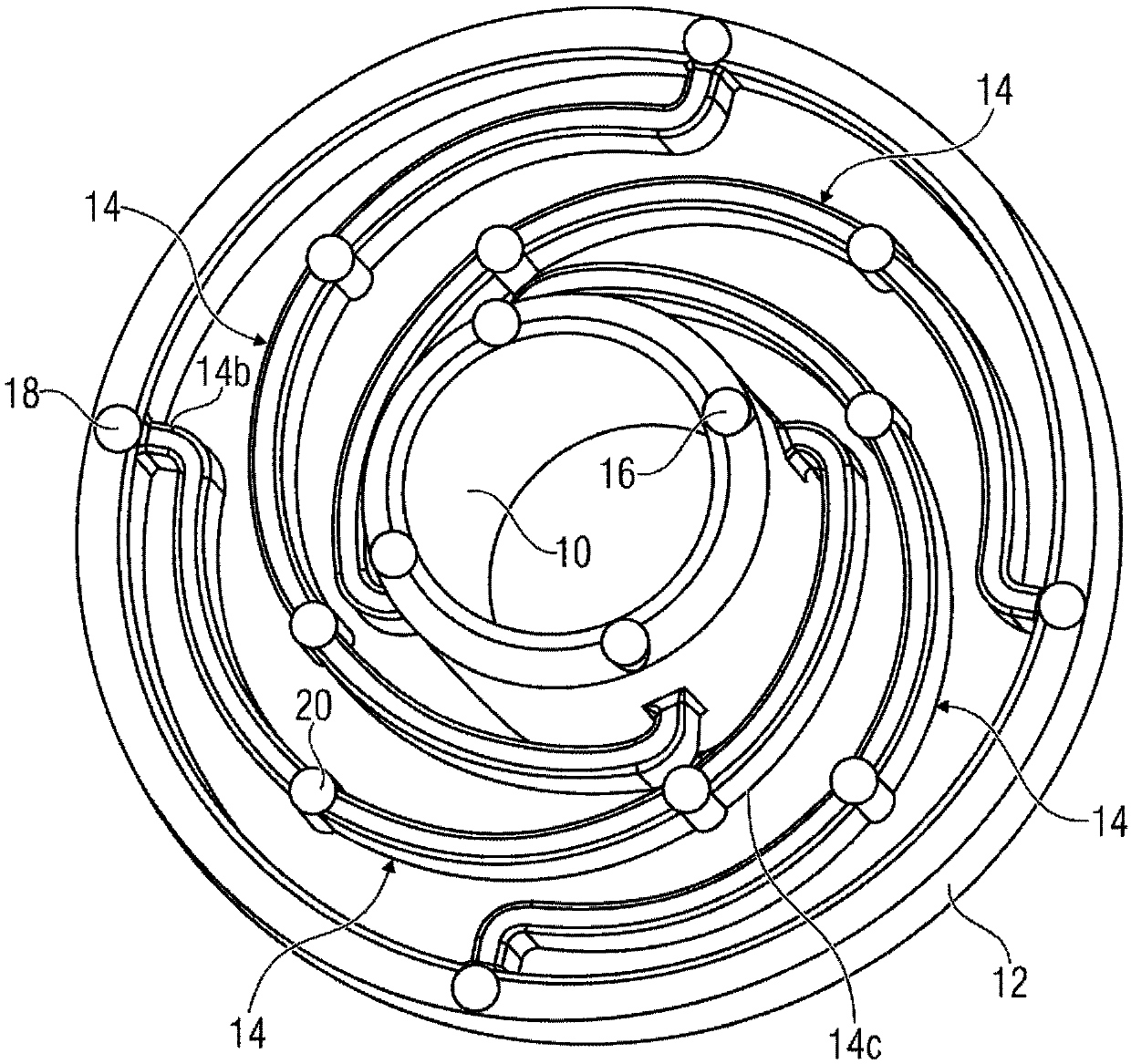

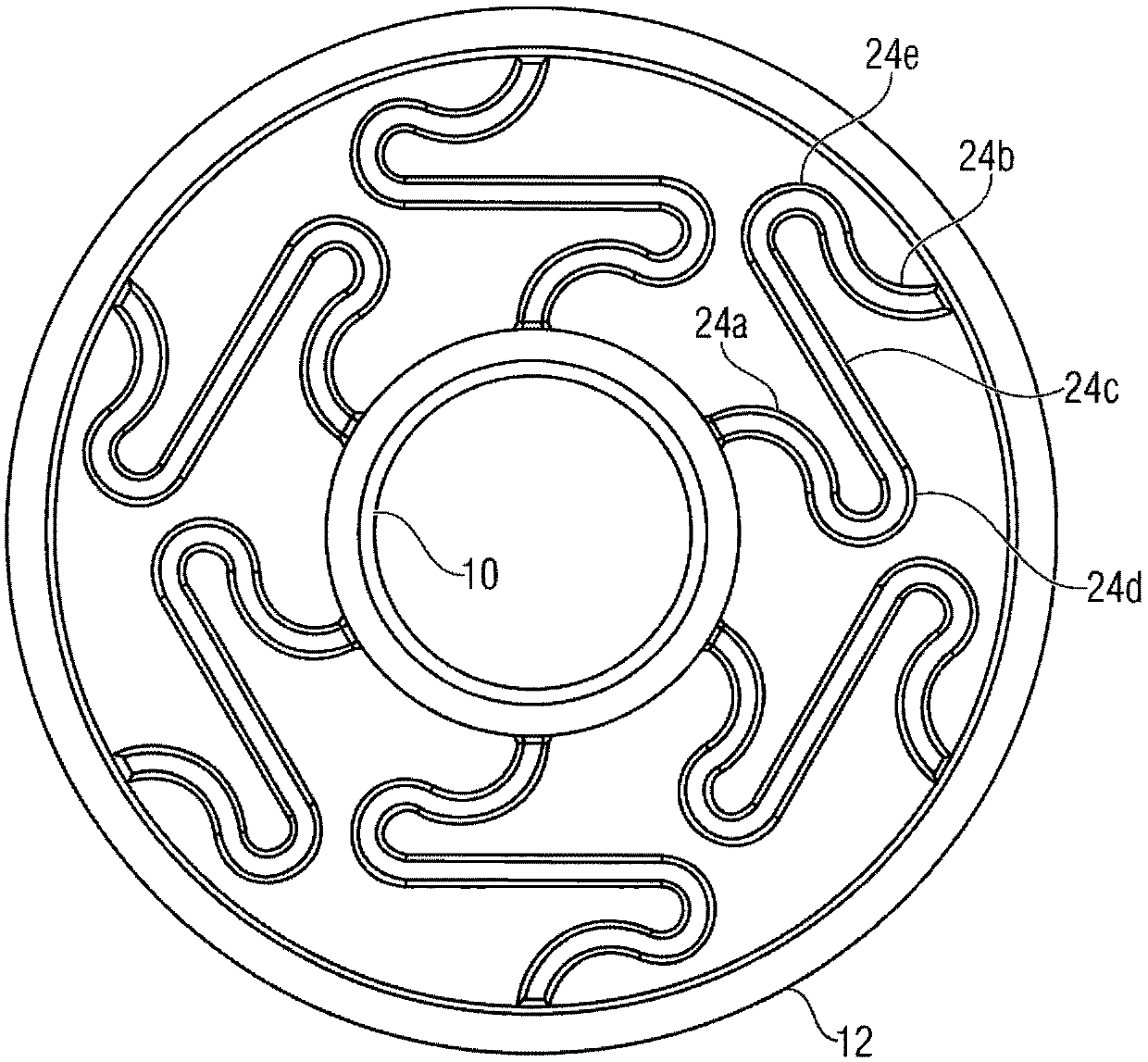

[0026] Embodiments of the invention relate to apparatus and methods for transporting and / or handling items, especially substrates such as silicon sheets, glass or foils. The invention relates to devices and methods for transporting and / or handling objects, especially thin substrates, such as silicon wafers, glass or foils. Such silicon flakes can, for example, have a thickness of less than 130 to 140 μm. However, embodiments of the invention can also be used for transporting or handling other items or articles, such as plate-shaped bodies. A plate-shaped body can here mean a body whose length and width are significantly greater than its thickness, for example 100 or 200 times greater. Thus, the length and width of said plate-shaped body define two substantially mutually parallel opposing main surfaces, said main surfaces representing the largest area of said plate-shaped body, having an area significantly larger than that connected to said main surfaces any side surface. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com