Pure-mechanical type welding jig

A welding fixture, a purely mechanical technology, applied in the field of purely mechanical welding fixtures, can solve problems such as uneven workpiece clamping and positioning, inability to clamp multiple workpieces, unfavorable welding speed, etc., to achieve accurate positioning, improve welding efficiency, and avoid The effect of inaccurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

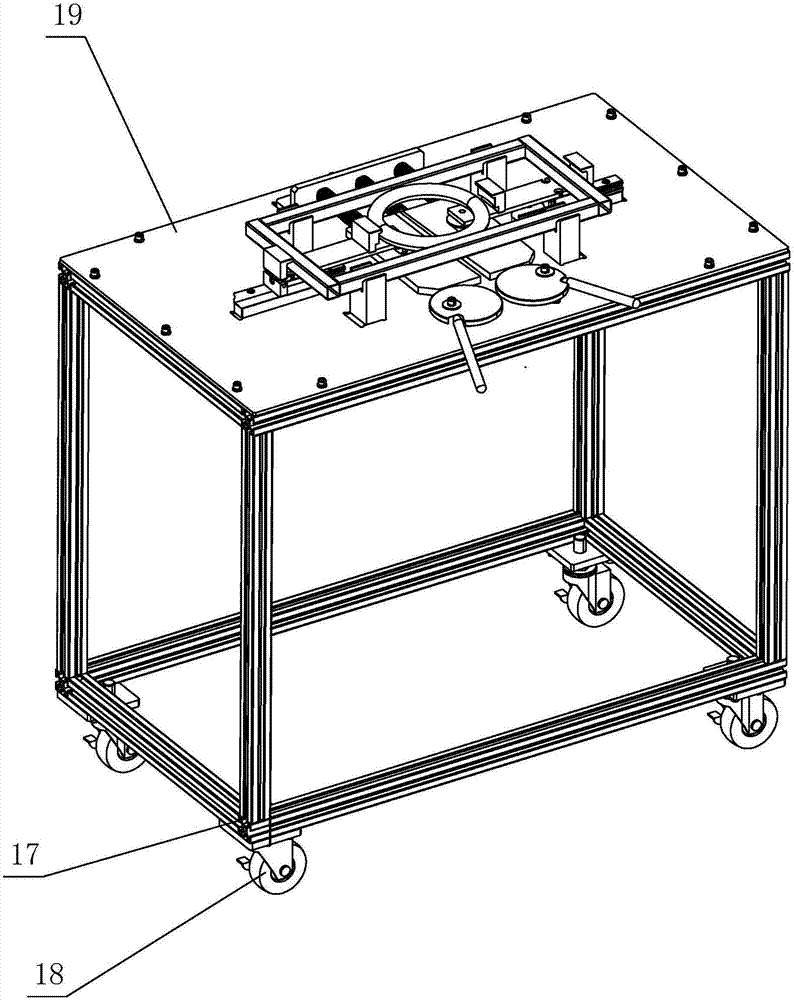

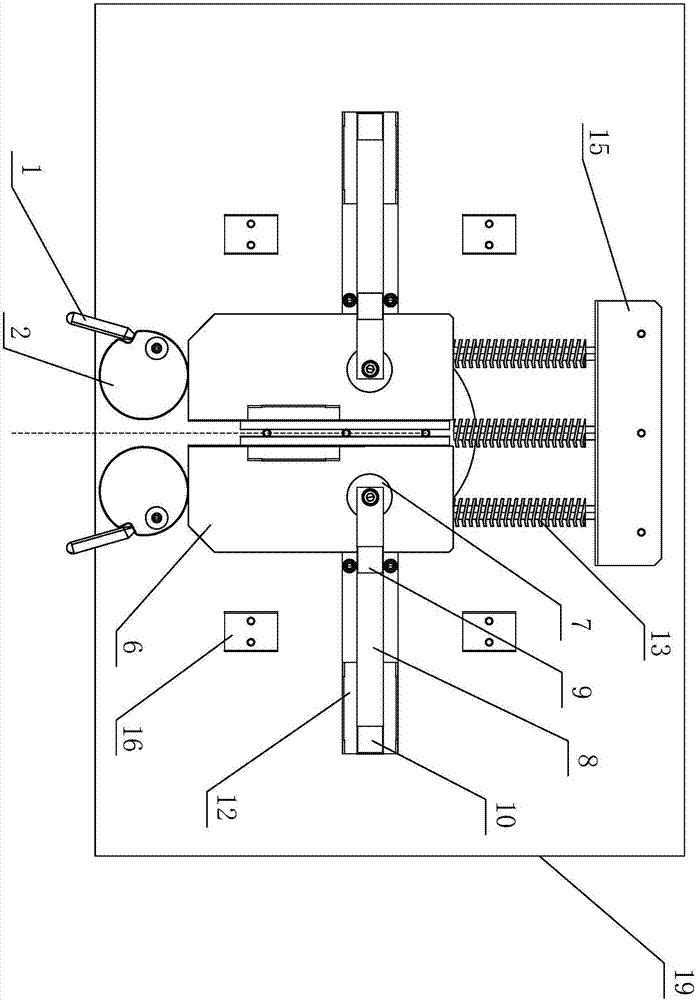

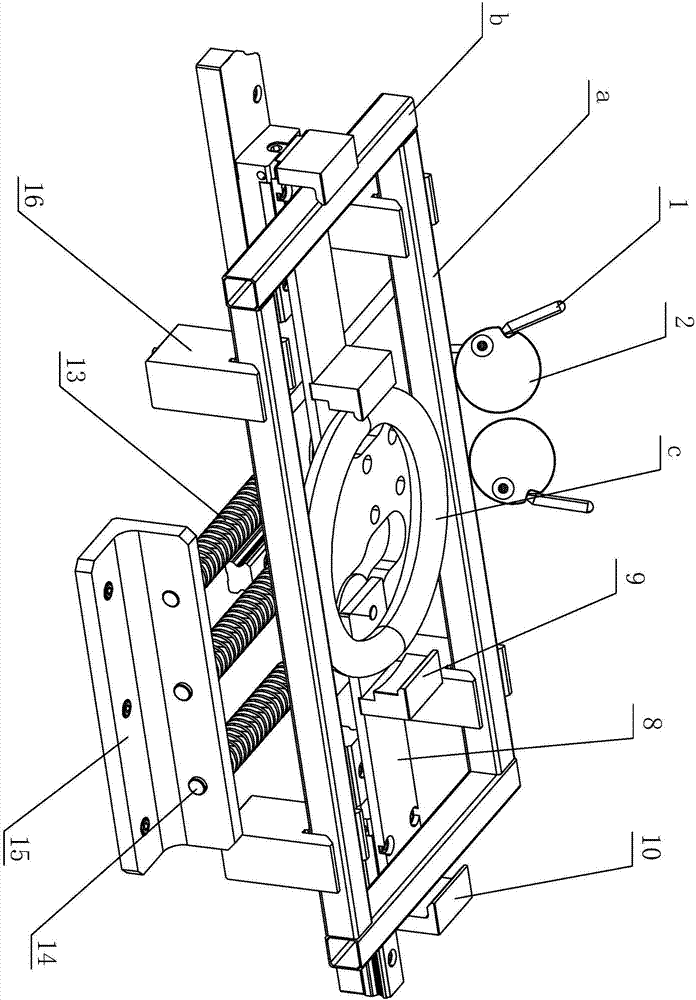

[0024] Such as figure 1 , figure 2 As shown, a purely mechanical welding fixture includes a frame 17 on which a welding platform 19 is installed, and a universal wheel 18 is installed on the bottom of the frame 17 . In this embodiment, in order to make the welding platform 19 adaptable to welding operators of different heights, the shown frame 17 can be telescopically adjusted in height. The specific structure is an existing structure similar to a retractable umbrella handle. The welding fixture also includes an initial positioning mechanism, a power source mechanism and a linkage mechanism installed on the welding platform 19 .

[0025] The initial positioning mechanism includes a plurality of positioning blocks 16 distributed in a rectangular structure. In this embodiment, the number of the positioning blocks 16 is 4, and of course it can also be 6, 8, etc. Each positioning block 16 is installed on the welding platform 19 through a tightening member, and the tightening m...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap