Steel box girder mounting method under clear height restricted condition

An installation method and technology of steel box girders, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as many potential safety hazards, impossibility of implementation, and cumbersome construction procedures, so as to improve construction efficiency, simplify construction procedures, reduce The effect of usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

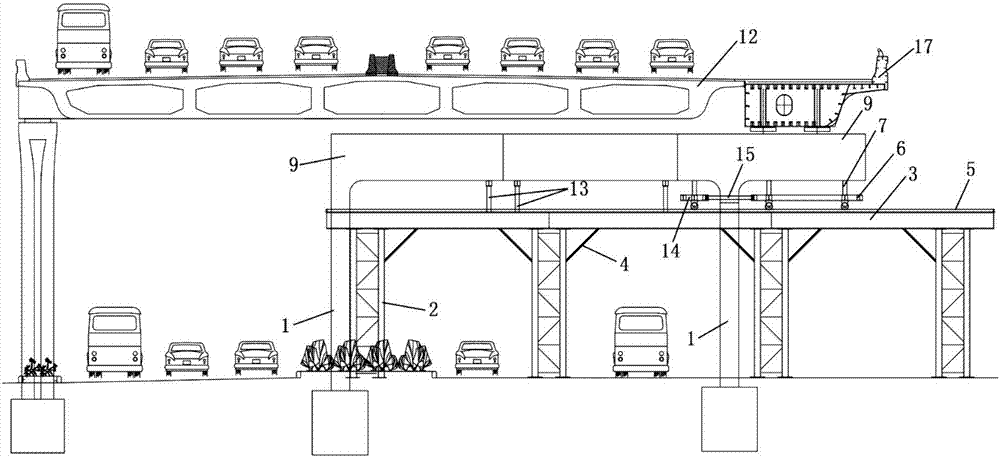

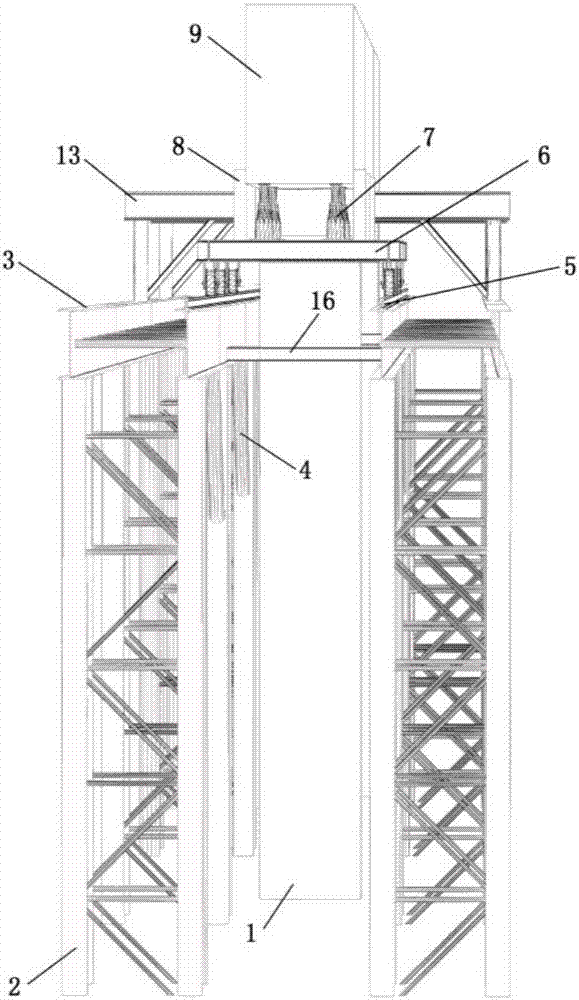

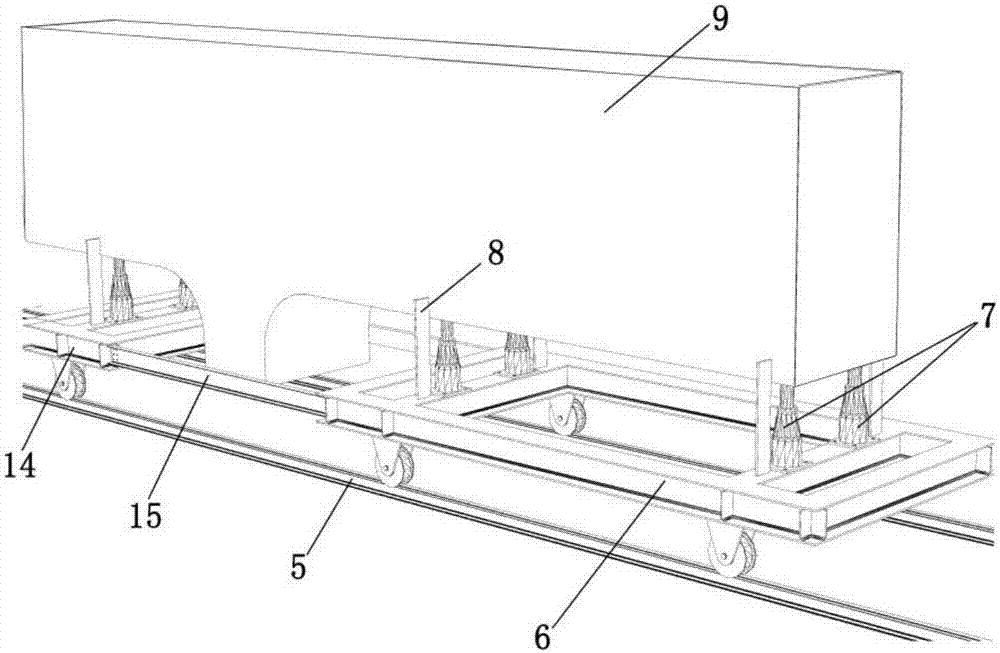

[0031] In order to have a clearer understanding of the technical features, objectives and effects of the present invention, the specific embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

[0032] Such as Figure 1-Figure 6 As shown, the method for installing a steel box girder in a restricted clear height state of the present invention includes the following steps:

[0033] S1: Column 1 is installed under the existing bridge 12. In this implementation, there are two steel columns. Column 1 is used to support steel box girder 9. Support systems, rail beams 3 and rails are arranged on both sides of the column 1, and the rail beams 3 on the left and right sides of the column 1 are connected by cross beams 16. The support system and the track beam 3 are modular structures, which are easy to disassemble and assemble. The supporting system includes a bracket 2 and a corner brace 4, and the corner brace 4 connects the brack...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap