A method of constructing a balance damper

A damper, balanced technology, applied in earthwork drilling, mine/tunnel ventilation, mining equipment, etc., can solve the problems of time-consuming construction, poor reliability and difficulty of wooden dampers, saving material waste and improving penetration efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A method for constructing a balanced damper,

[0019] 1. Weld three seamless steel pipes with a diameter of 40mm, a wall thickness of 3.5mm, and a length of 2m at equal distances from the top frame and the side frames of the balance damper;

[0020] 2. According to the position where the balance damper is to be installed, select three anchor rods at the side of the road, and thread the protruding part of the anchor rod with three fixed rods with a diameter of 40mm, a wall thickness of 3.5mm, and a length of 1m. 3 anchor rods, connect the protruding part of the anchor rod with three fixed rods with a diameter of 40mm, a wall thickness of 3.5mm, and a length of 1m. One end of the fixed rod is provided with an internal thread that matches the thread of the anchor rod;

[0021] 3. Use a connecting rod with a diameter of 40mm, a wall thickness of 3.5mm, and a length of 4m to connect the fixed rods at the side of the road and the roof of the road through fasteners to form a r...

Embodiment 2

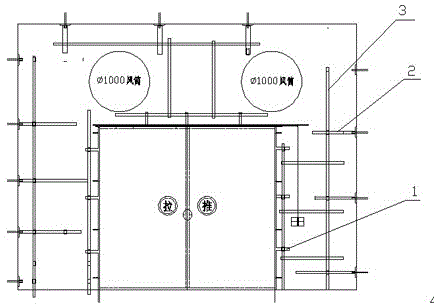

[0028] like figure 1 , 2 As shown, a method of building a balanced damper,

[0029] 1. Weld seamless steel pipe 1 on the top frame and side frames of the balance damper;

[0030] 2. Thread the fixed rod 2 to the protruding part of the anchor rod on the side of the road and the roof of the road, and one end of the fixed rod is provided with an internal thread that matches the thread of the anchor rod;

[0031] 3. Connect the fixed rod to the seamless steel pipe through the connecting rod 3 and the fastener;

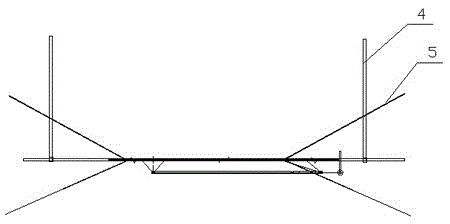

[0032] 4. Lead the steel wire rope 5 from the door frame of the balance damper to connect with the ladder beam at the side of the lane;

[0033] 5. Use the support rod 4 to fix the temporary damper in the downwind direction of the roadway. One end of the support rod 4 is connected to the connecting rod through a fastener, and the other end is embedded in the bottom plate. The angle between the support rod and the bottom plate is 45-75 degrees;

[0034] 6. Use mesh to c...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap