Method for manufacturing combined permeable bricks

A manufacturing method and technology of permeable bricks, which are applied to pavements, roads, buildings and other directions paved with prefabricated blocks, can solve the problems of affecting pedestrian travel, road brick mud water splashing, and affecting rainwater seepage, so as to reduce road surface water , Accelerate the infiltration of rainwater and facilitate the infiltration of rainwater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

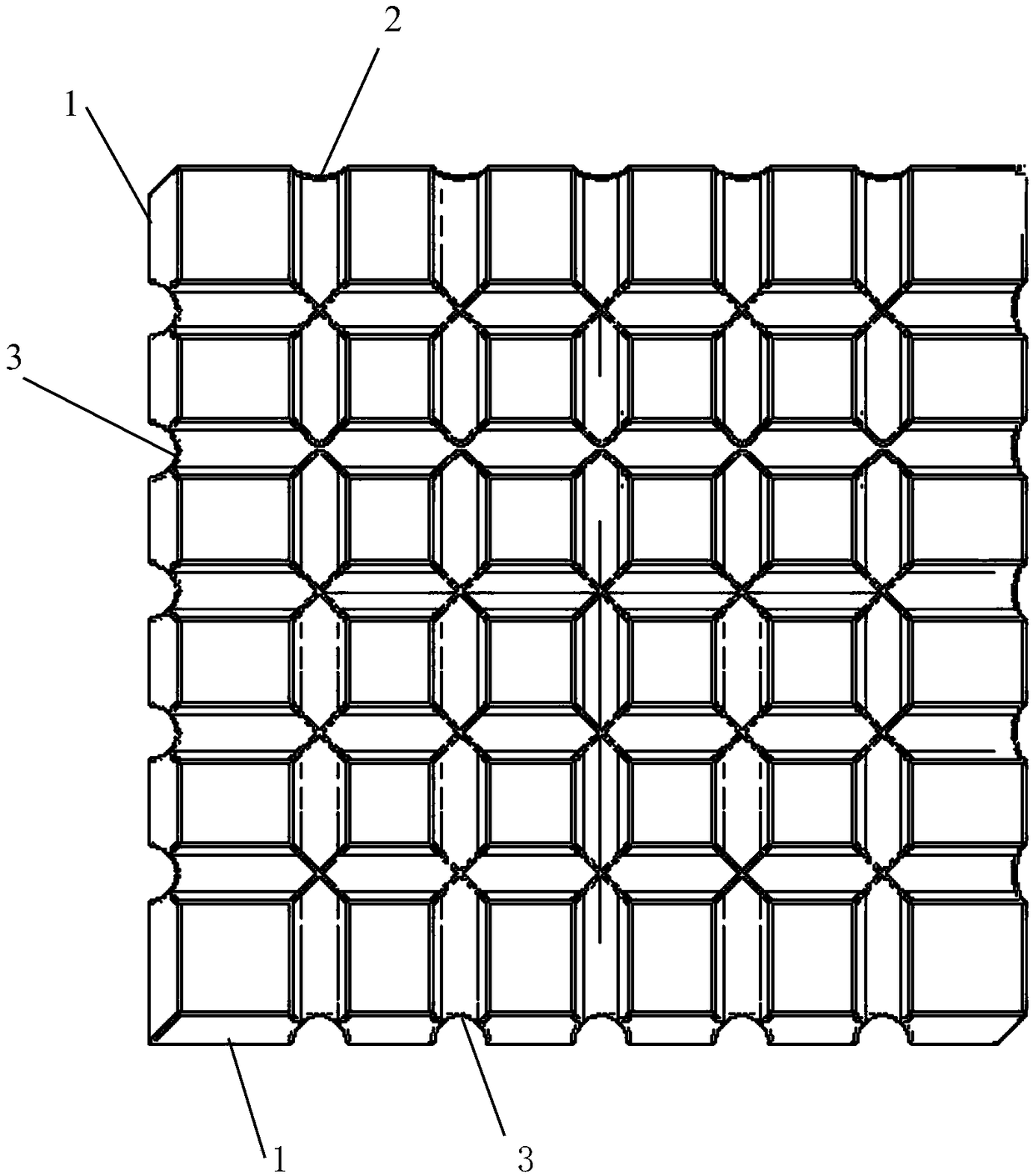

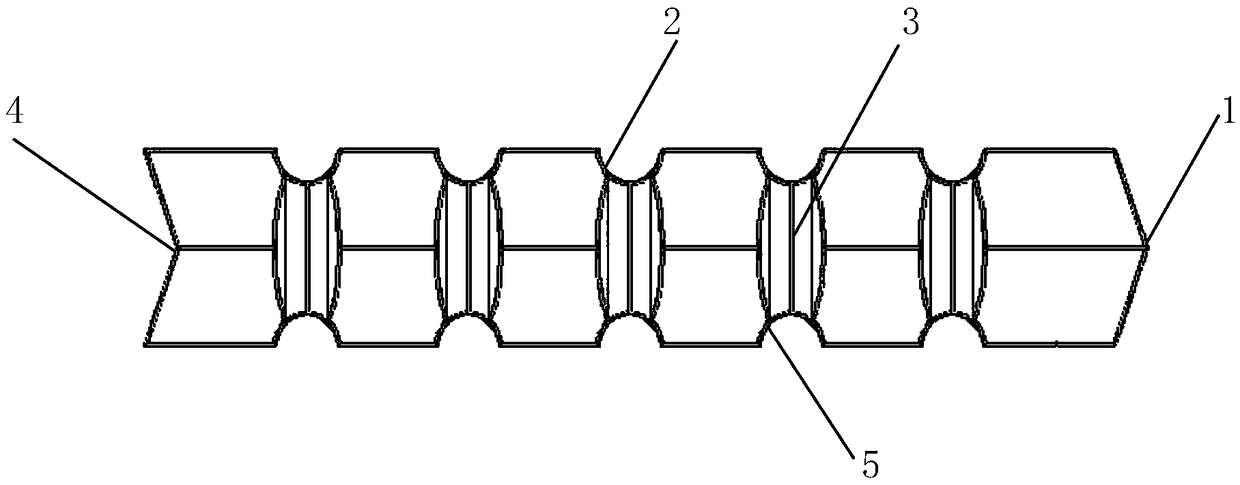

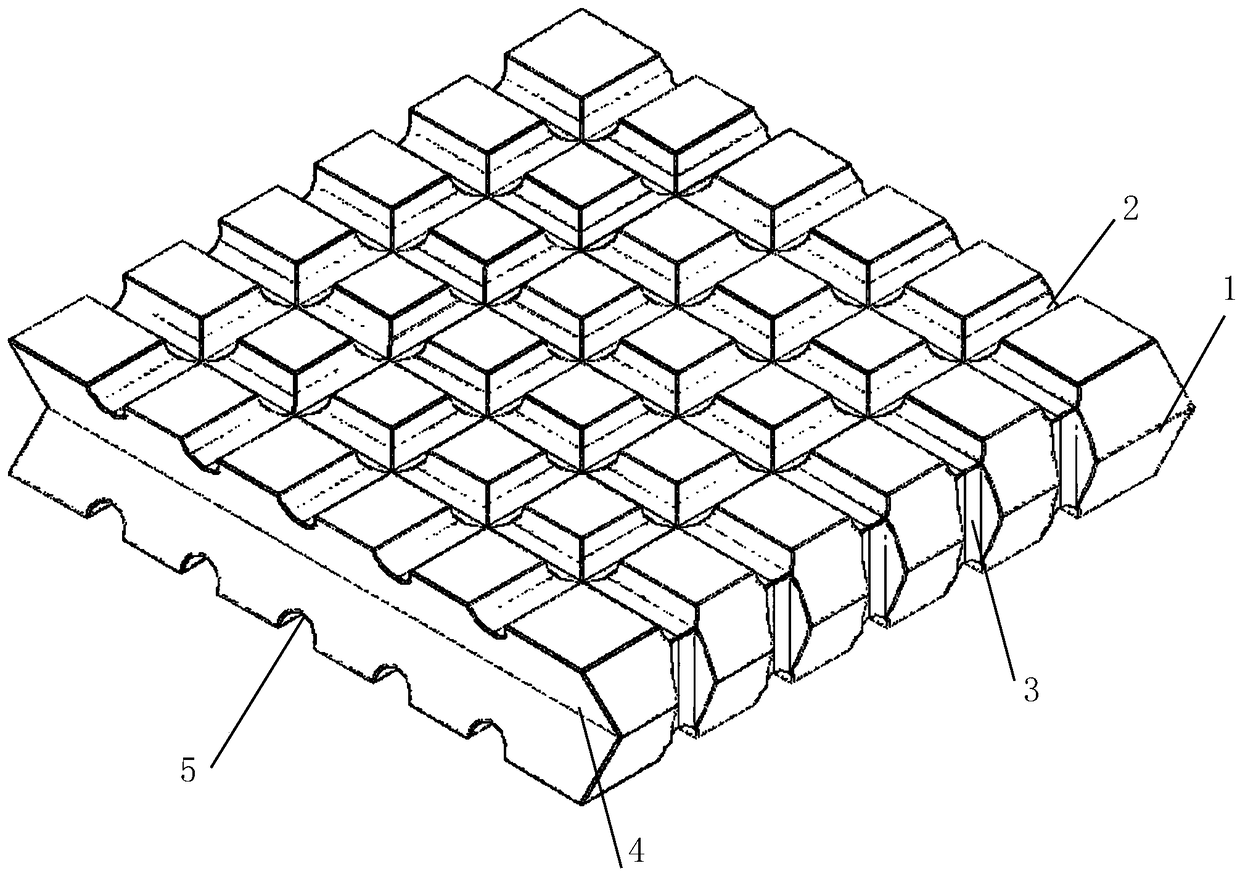

[0023] Embodiment: refer to attached Figure 1-3 , a combined permeable brick, including a permeable brick body, the right side and rear side of the permeable brick body are provided with fixing protrusions 1, and the corresponding positions on the left side and the front side of the permeable brick body are provided with fixing protrusions Matching the groove 4, the permeable brick body is provided with a drainage hole 3 that runs through from top to bottom.

[0024] In a further preferred solution, the drainage holes 3 are arranged on the fixing protrusion 1 and are evenly distributed.

[0025] In a further preferred solution, the cross section of the fixing protrusion 1 is an isosceles triangle, and the cross section of the groove 4 matches the fixing protrusion 1 .

[0026] In a further preferred solution, horizontal and / or longitudinal anti-skid grooves 2 are provided on the front of the permeable brick body, and horizontal and / or longitudinal drainage grooves 5 are prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com