Pressure induction device of hydraulic prop

A technology of induction device and hydraulic prop, which is applied in the direction of prop/bracket, mining equipment, earthwork drilling, etc., can solve the problems of unbalanced pressure of hydraulic prop, increase of production expenditure, and affecting the life safety of staff, so as to achieve pressure balance and production The effect of reducing expenses and protecting life safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

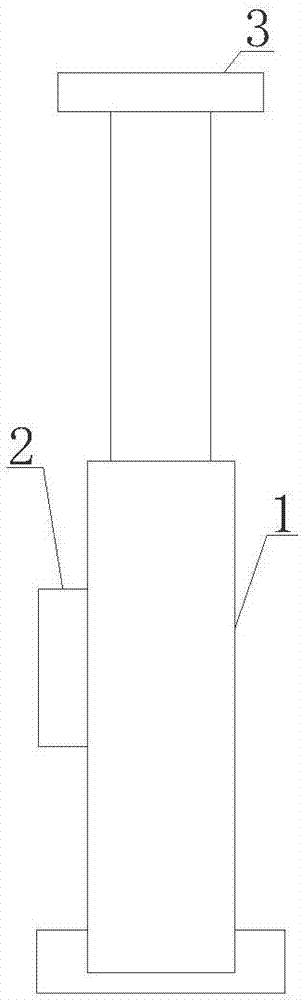

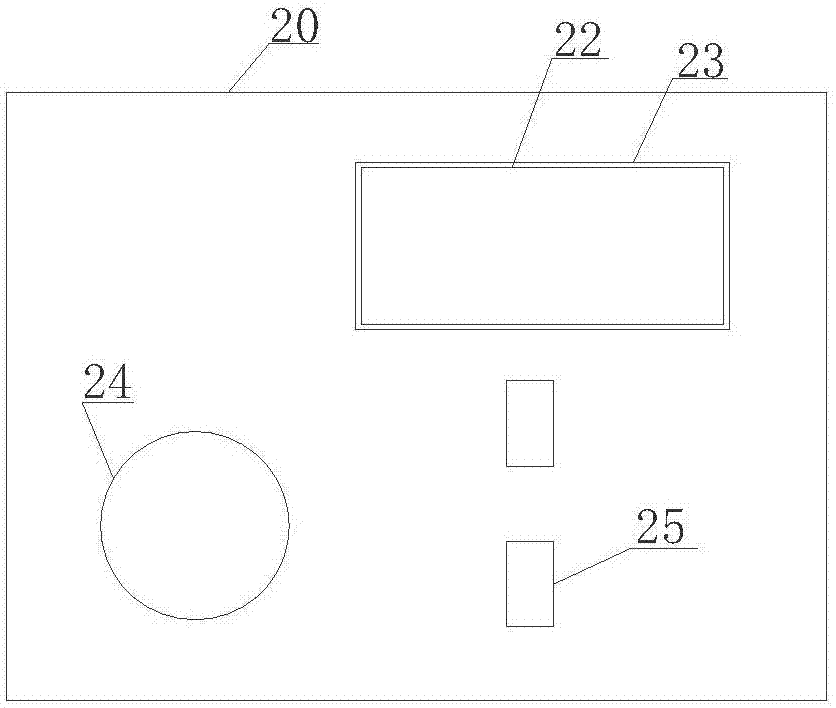

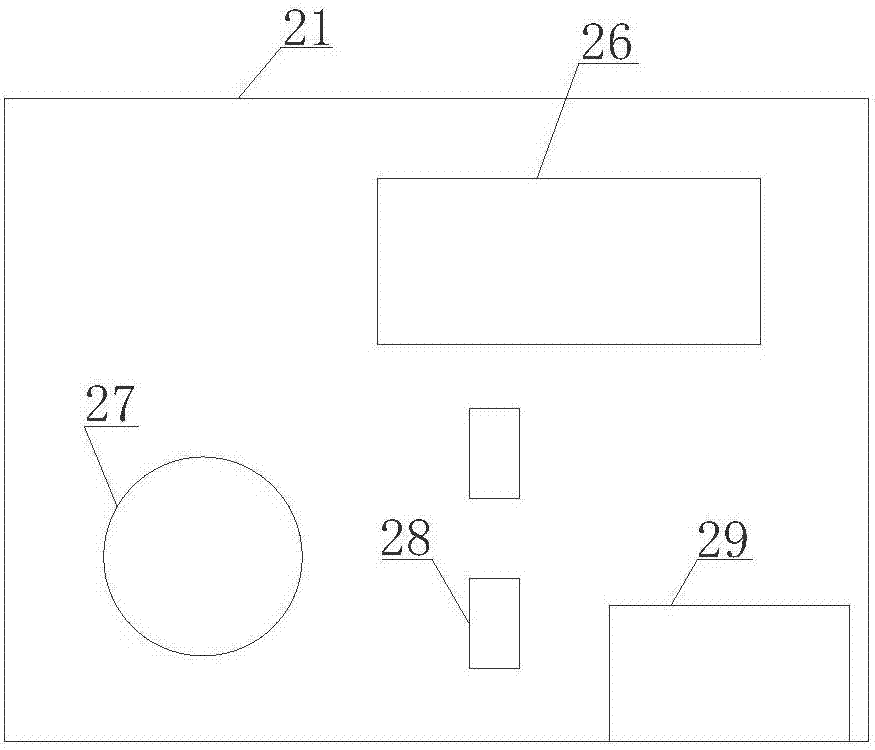

[0018] Such as Figure 1 to Figure 6 As shown, the pressure sensing device of the hydraulic prop is composed of a column body 1, a master control device 2, and a top cover device 3. The top cover device 3 is installed at one end of the column body 1, and the master control device 2 is fixedly installed on the On the cylinder 1; the master control device 2 is composed of the shell I20, the shell II21, the protective cover 22, the through hole I23, the through hole II24, the through hole III25, the display screen 26, the key I27, the key II28 and the control center 29. The shell I20 It is snapped together with the casing II21 to form the casing of the master control device 2. The surface of the casing I20 has through holes I23, through holes II24 and through holes III25. The protective cover 22 is embedded in the through holes I23. The display screen 26, buttons I27, II...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com