Radial-direction momentarily-changing mechanism of scroll compressor

A scroll compressor and variable technology, applied in the field of scroll compressors, can solve the problem of oil content in the compressed medium, and achieve the effects of reducing unbalance, reducing wear and large area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

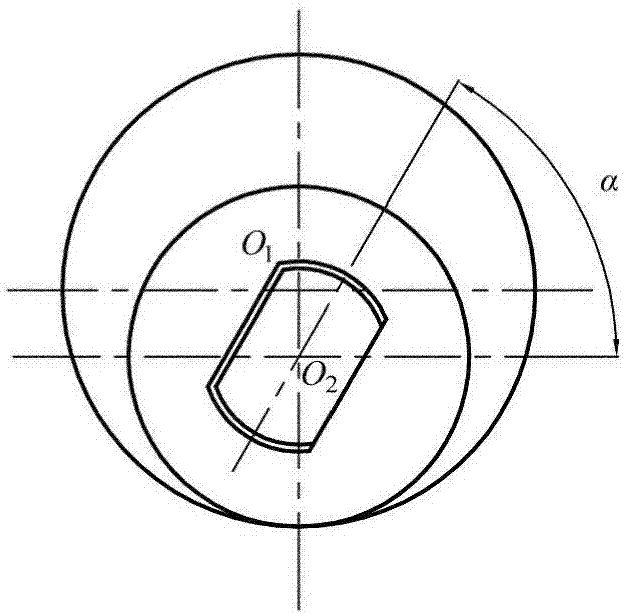

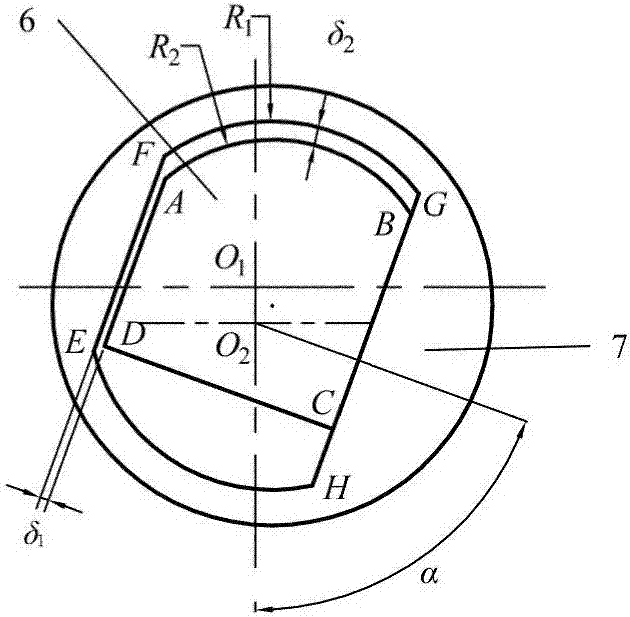

[0029] like figure 1 As shown, in the existing slider-type radial follow-up mechanism, the wedge-shaped driving surface of the crank pin forms an included angle less than 90 degrees with the moving direction of the orbiting scroll element in the compression device, so that the driving force generates a radial distribution. The force overcomes the radial separation force acting on the movable scroll element and is proportional to the pressure of the compressed fluid to achieve the purpose of radial follow-up. But the center of gravity of the crank pin of this mechanism is far away from the center of rotation of the main shaft O 1 , resulting in a large rotational inertial force and poor dynamic balance performance.

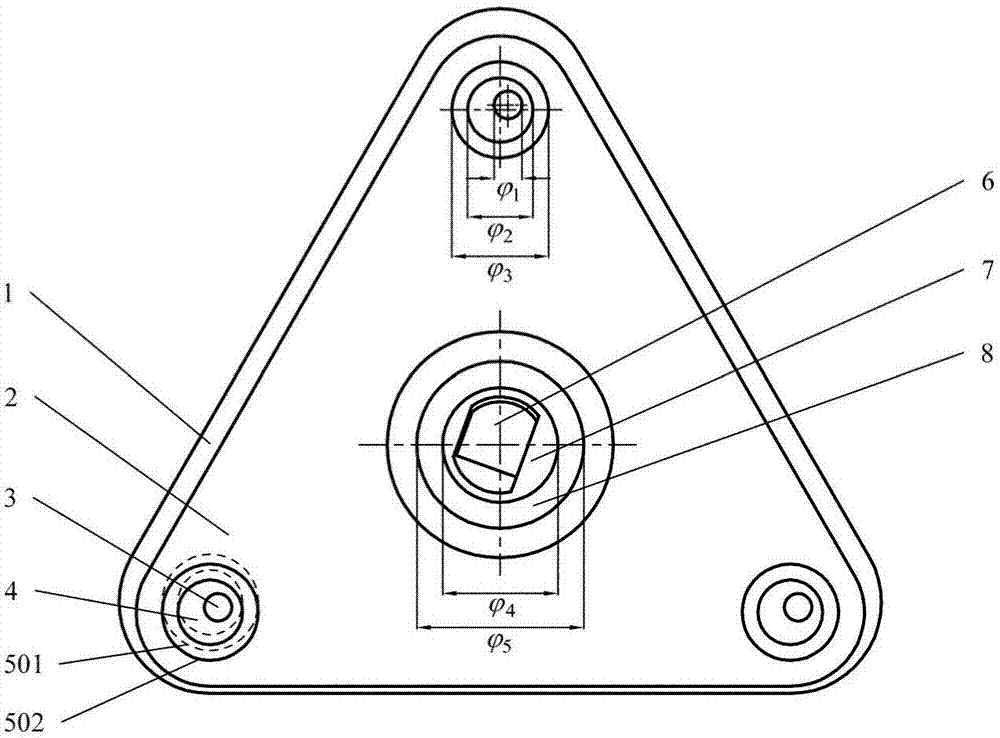

[0030] like figure 2 As shown, the fixed scroll (1) is fixed, and the movable scroll (2) is engaged with it after installation. Spindl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap