Heat radiation structure of LED lamp

A technology of LED lamps and heat dissipation structure, which is applied to the cooling/heating device of lighting devices, lampshades, lighting and heating equipment, etc., which can solve the problems of LED chip failure, restricting the service life of LED lamps, and reducing the luminous efficiency of lamps. Simplicity and the effect of improving heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

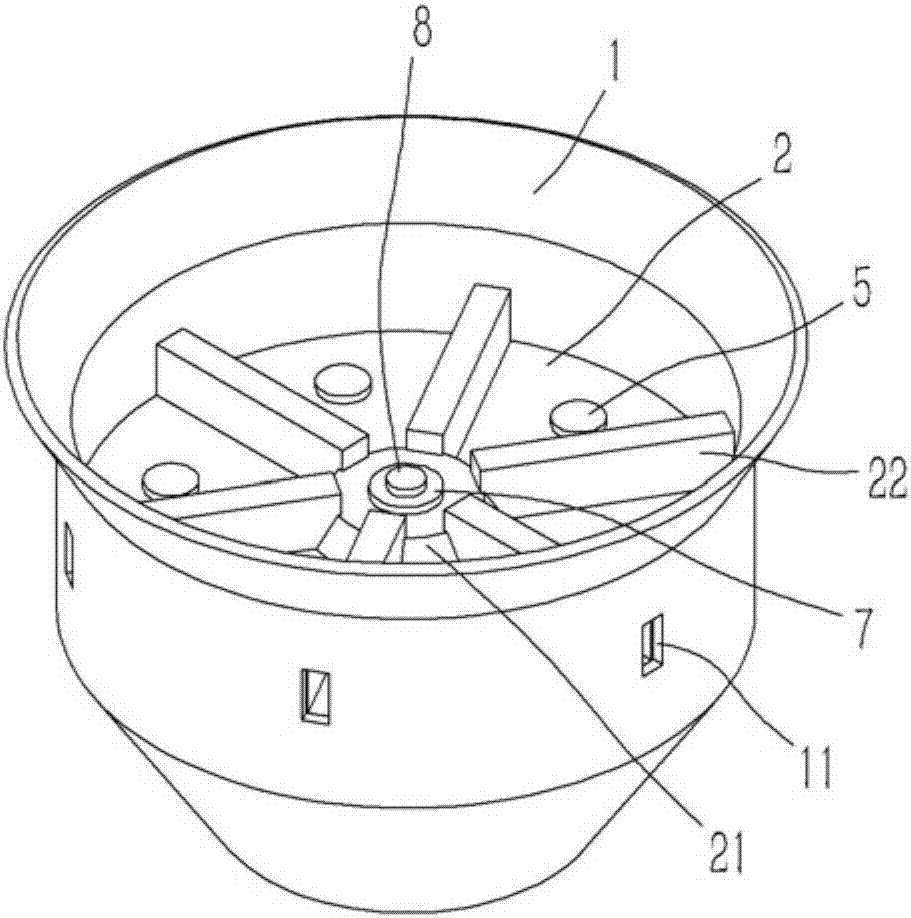

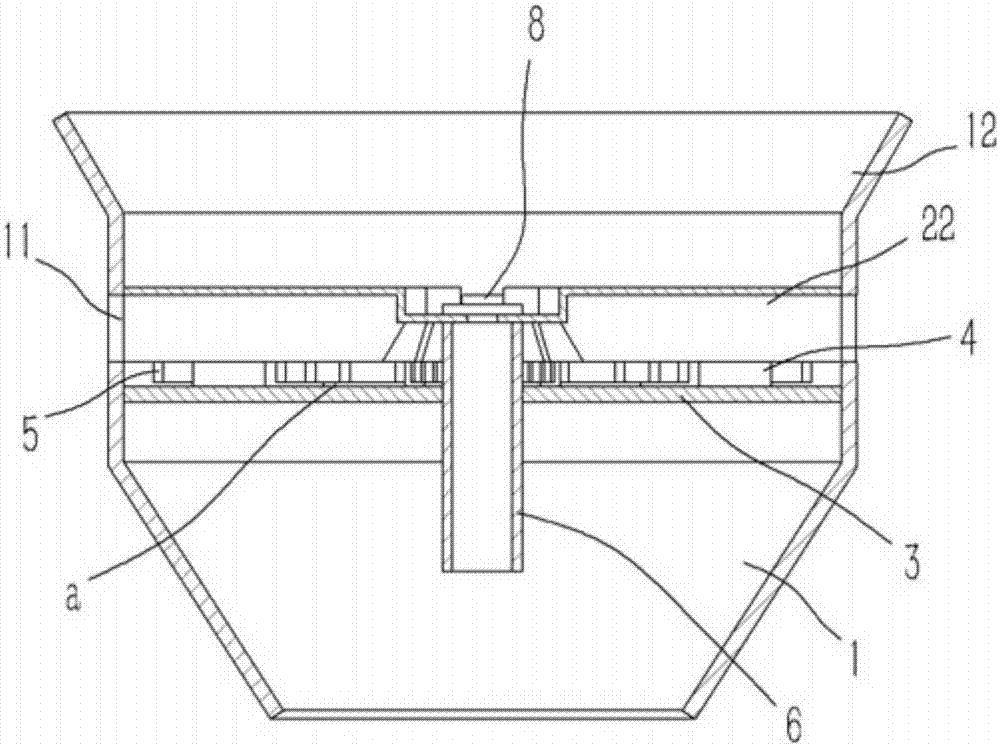

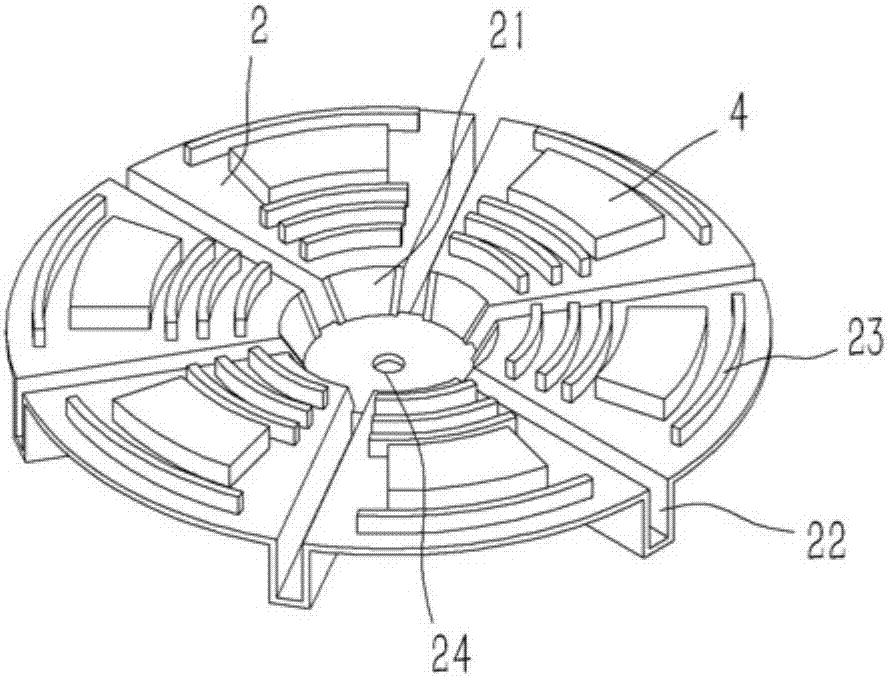

[0017] Example: see Figures 1 to 3 As shown, a heat dissipation structure of an LED lamp includes a lampshade 1 of the LED lamp. A heat dissipation aluminum plate 2 is inserted into the lampshade 1. The middle part of the heat dissipation aluminum plate 2 is stamped and formed with an upwardly protruding round platform 21. The heat dissipation aluminum plate 2 around the round platform 21 is There are several upwardly protruding cooling passages 22 formed by the upper stamping. The cooling passages 22 communicate with the inner cavity of the round table 21. The side wall of the lampshade 1 is formed with a cooling hole 11 communicating with the cooling passages 22 on the heat dissipation aluminum plate 2. The bottom surface of the heat dissipation aluminum plate 2 adjacent to the heat dissipation channel 22 is against the spacer 4, the screw 5 passes through the heat dissipation aluminum plate 2 and is screwed on the spacer 4, the spacer 4 is fixed on the baffle 3, and the baf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com