Liquid oxygen mass flow measurement method for liquid oxygen kerosene engine test

A mass flow and measurement method technology, applied in the field of liquid oxygen kerosene engine test liquid oxygen mass flow measurement, can solve problems such as failure to meet accuracy requirements, failure to obtain flowmeter calibration coefficients, system errors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be further described below in conjunction with accompanying drawing.

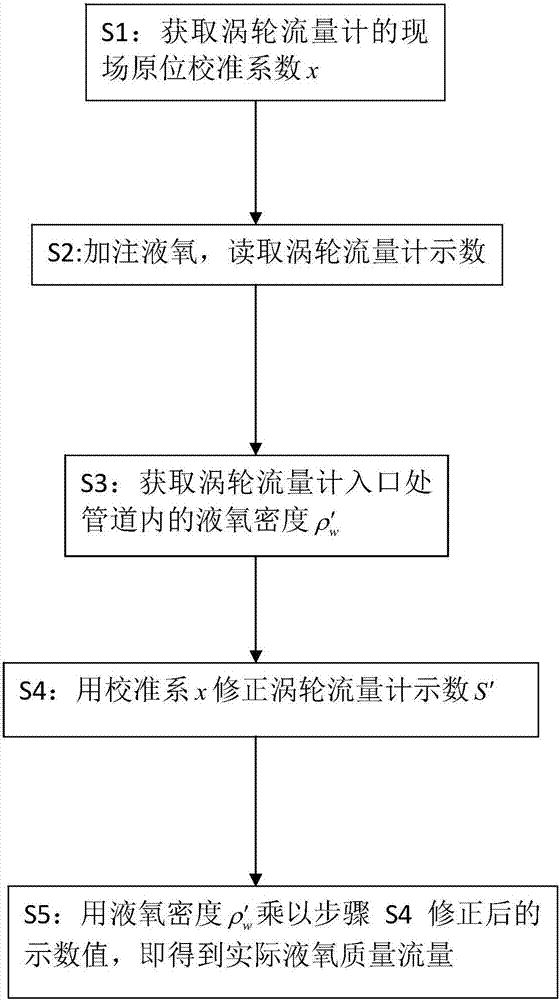

[0058] join figure 1 , the liquid oxygen kerosene engine test liquid oxygen flow measurement method provided by the present invention comprises the following steps:

[0059] Step 1 Perform on-site in-situ calibration of the turbine flowmeter:

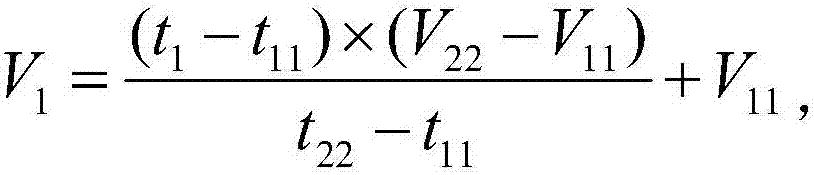

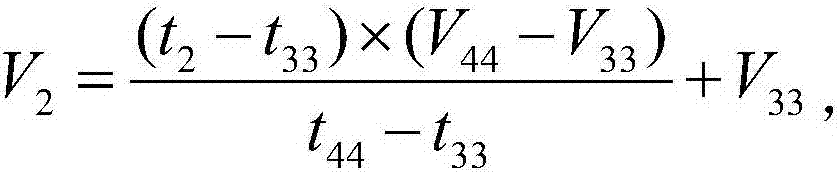

[0060] 1.1) Use the capacity comparison method to calibrate the volume of the liquid oxygen container corresponding to different liquid level heights, so as to compile the liquid level height-volume comparison table of the liquid oxygen container. The specific method is:

[0061] 1.1.1) Place the standard container on the lower platform of the liquid oxygen container, and fix and level the standard container;

[0062] 1.1.2) Connect the discharge port of the liquid oxygen container with the standard container, and ensure that there is no leakage at the connection;

[0063] 1.1.3) Fill the liquid oxygen container with water until i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap