Rose black tea and processing method thereof

A technology of rose black tea and its processing method, which is applied in the field of tea, can solve the problems of wasting rose petals, inability to replenish qi and blood, nourish the skin, adjust menstruation, calm the liver and moisten the lungs, etc., and achieve the goal of slowing down the fermentation temperature, good health care effect, and expanding the audience Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

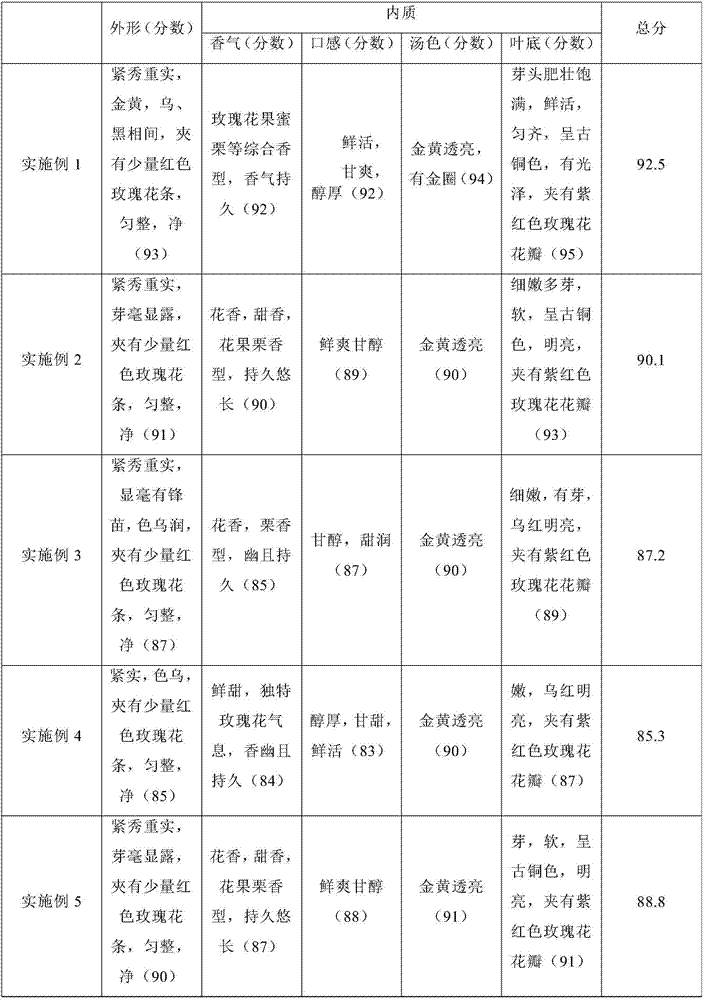

Examples

Embodiment 1

[0021] A kind of processing method of rose black tea, it comprises the following steps:

[0022] Grading According to the picking standard, grade the fresh leaves of Xinyang No. 10, and separate the bud head, one bud and one leaf, one bud and two leaves, and one bud and three and four leaves; take some half-open roses, and pick off the rose petals for later use;

[0023] Withering: 0.4kg / m according to the amount of spread leaves 2 , spread the rose petals to a thickness of 2cm, wither in the sun, stir once every 20 minutes, and wither for 30 minutes to obtain the withered rose petals; the amount of leaves spread is 1.0kg / m 2 , spread the buds to a thickness of 2-3cm, wither in the sun, stir once every 10min, and wither for 20min to obtain the withered semi-finished product to obtain the withered semi-finished product; Next, the withered semi-finished product is withered for 12 hours to obtain withered leaves with dark green softness, soft hand grip, dull leaf surface, contin...

Embodiment 2

[0028] A kind of processing method of rose black tea, it comprises the following steps:

[0029] Grading According to the picking standard, grade the fresh leaves of Xinyang No. 10, and separate the bud head, one bud and one leaf, one bud and two leaves, and one bud and three and four leaves; take some half-open roses, and pick off the rose petals for later use;

[0030] Withering: 0.7kg / m according to the amount of spread leaves 2 , spread the rose petals to a thickness of 2cm, wither in the sun, stir once every 10 minutes, and wither for 40 minutes to obtain the withered rose petals; according to the amount of leaves spread, it is 0.6kg / m 2 , spread out one bud and one leaf to a thickness of 2-3 cm, wither in the sun, stir once every 20 minutes, and wither for 60 minutes to obtain the withered semi-finished product; then at a temperature of 28-30 ° C and a relative humidity of 60 % under the condition of withering the semi-finished product for 10 hours to obtain withered le...

Embodiment 3

[0035] A kind of processing method of rose black tea, it comprises the following steps:

[0036] Grading According to the picking standard, grade the fresh leaves of Xinyang No. 10, and separate the bud head, one bud and one leaf, one bud and two leaves, and one bud and three and four leaves; take some half-open roses, and pick off the rose petals for later use;

[0037] Withering: 0.5kg / m according to the amount of spread leaves 2 , spread the rose petals to a thickness of 2 to 3 cm, wither in the sun, stir once every 15 minutes, and wither for 40 minutes to obtain the withered rose petals; the amount of leaves spread is 0.8 kg / m 2 , spread out one bud and two leaves until the thickness is 2-3cm, carry out withering in sunlight, turn over once every 15min, and wither for 45min to obtain the withered semi-finished product; then at a temperature of 28-30°C and a relative humidity of 65 % under the condition of withering the semi-finished product withering for 11 hours to obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com