Multifunctional rice milling machine capable of removing impurities

A rice mill, multi-functional technology, applied in the direction of solid separation, filter screen, grille, etc., can solve the problems of reduced work efficiency, high failure rate, loss of grain, etc., to achieve convenient operation and maintenance, low failure rate, and air intake big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

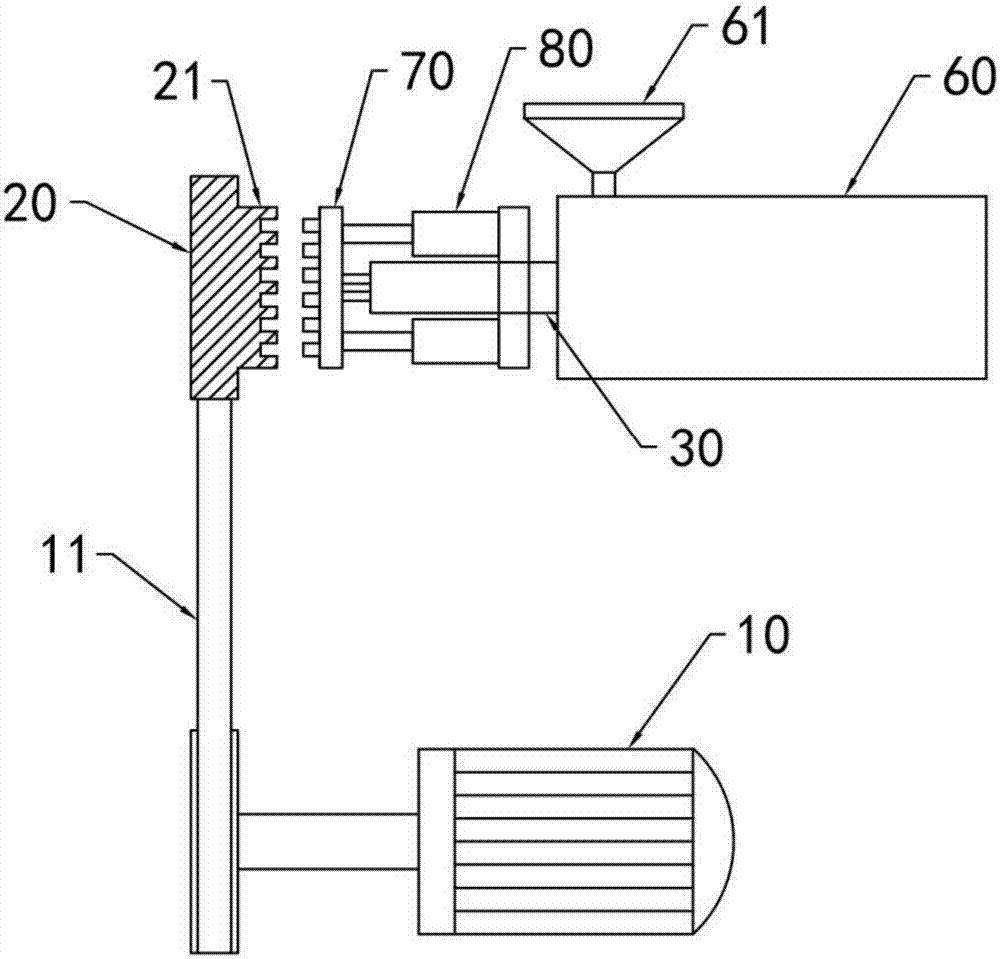

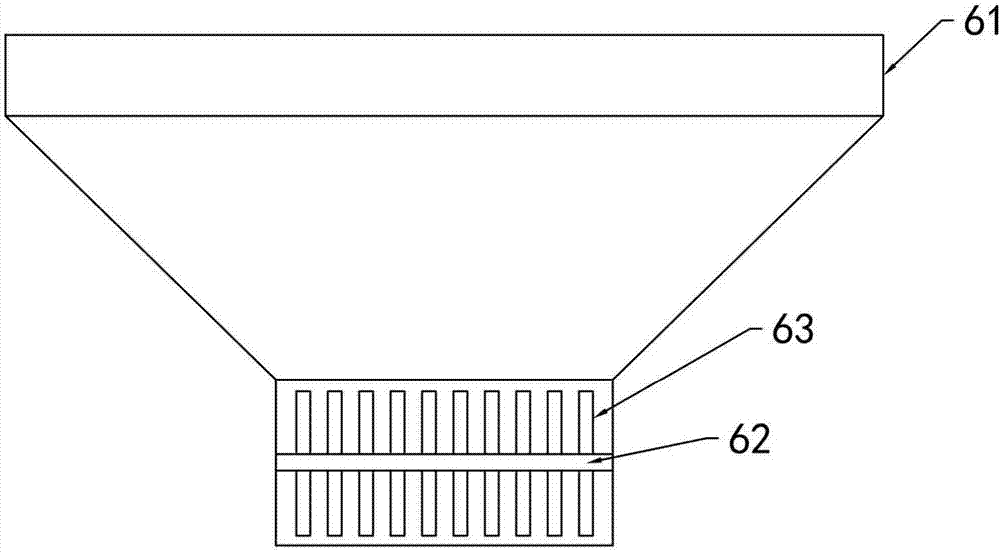

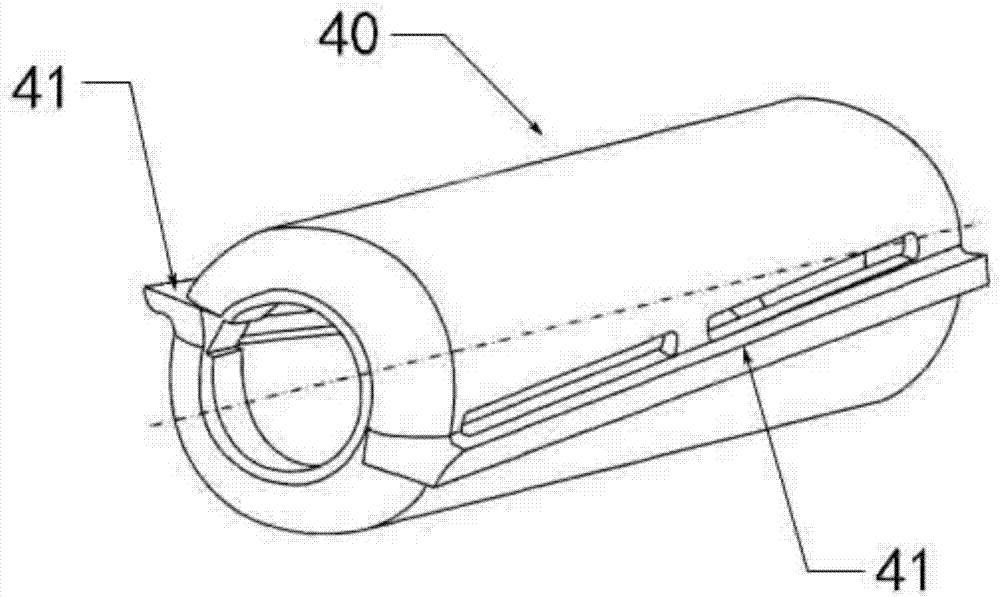

[0028] Such as Figure 1-4 Shown, a kind of impurity-removing multifunctional rice milling machine includes drive motor 10, belt pulley 20, rice milling machine main shaft 30, rice milling roller 40, rice milling sieve and spline cover 70; described rice milling machine main shaft 30 One end is provided with rice milling roller 40, and the other end of described rice mill main shaft 30 is provided with cross keyway, and one end of described spline cover 70 is provided with the cross key that is connected with cross keyway, and described spline cover 70 is far away from rice milling. One side of the machine main shaft 30 is provided with a pulley 20, and the side of the pulley 20 close to the spline sleeve 70 is provided with a boss 21 cooperating with the spline sleeve 70, and the pulley 20 is connected to the output of the drive motor 10 through the belt 11. Shaft, described belt pulley 20, boss 21, spline sleeve 70 and rice mill main shaft 30 coaxial settings; Described rice...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com