Automobile fuel tank fixed steel belt multi-station progressive die

An automotive fuel tank and multi-station technology, which is applied to forming tools, manufacturing tools, positioning devices, etc., can solve the problems of complex processing, long processing cycle, and low production efficiency, and achieve high degree of automation, high processing accuracy, and improved The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

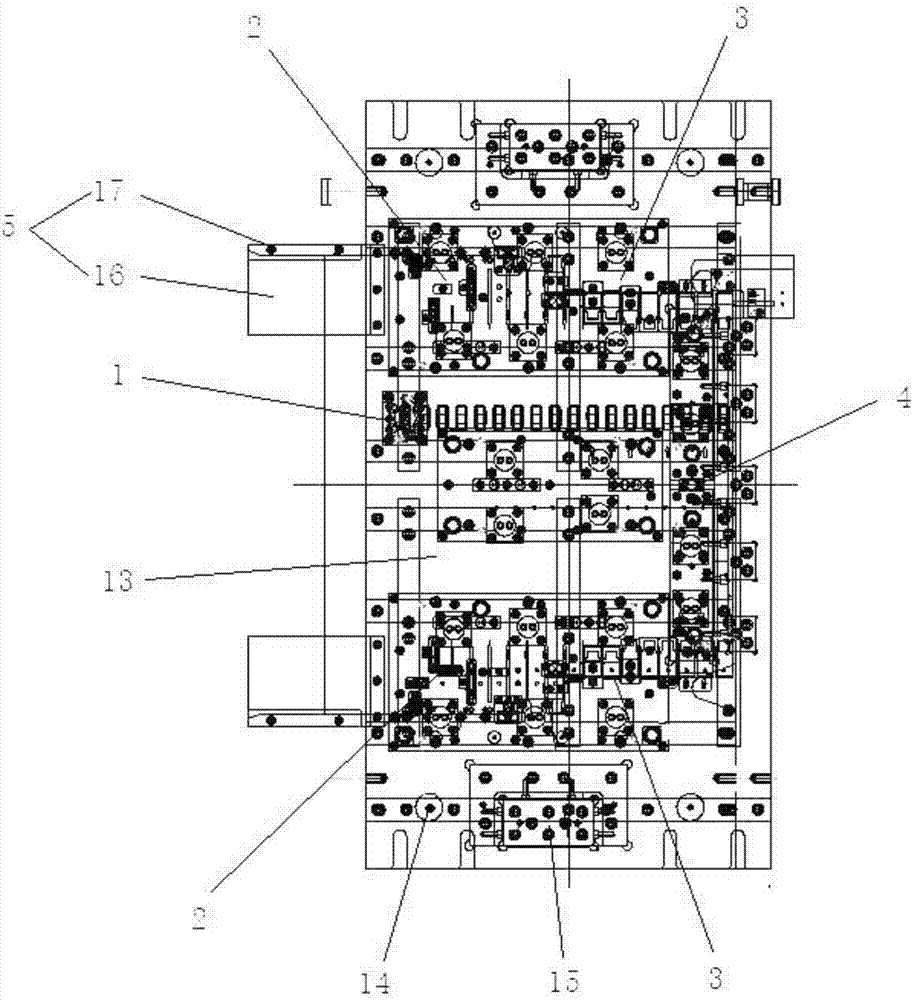

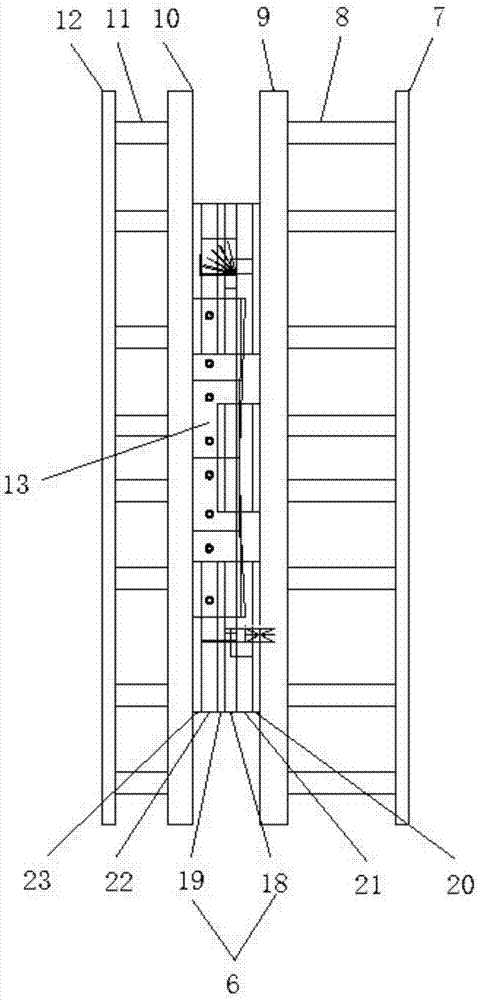

[0021] A kind of fixed steel band multi-station progressive die of automobile oil tank shown in the present invention, as figure 1 , figure 2 As shown, it includes: an upper mold base assembly, a lower mold base assembly, and a convex convex assembly 1, a trimming assembly 2, a bending assembly 3, a cutting assembly 4, a material guide assembly 5 and a discharge assembly 6; wherein, the upper mold The frame assembly includes an upper pallet 7, an upper pad 8, and an upper mold base 9 distributed from top to bottom, and the lower mold frame assembly includes a lower mold base 10, a lower pad 11, and a lower pallet distributed from top to bottom. 12. The material guide assembly 5 includes a material guide plate 16 and guide pins 17 distributed side by side on the material guide plate 16, and the unloading assembly 6 includes an upper splint 18 and a stripping plate 19 distributed up and down; the material guide assembly 5 is set On the side of the lower mold base assembly; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com