Magnetic suction disc assembly with automatic adjustment and adaption function

A magnetic sucker and automatic adjustment technology, applied in the direction of manufacturing tools, manipulators, chucks, etc., can solve the problems of reduced adsorption force, large hollowing, and workpiece falling off, so as to increase or decrease the adsorption force, improve the adsorption force, and realize self-adaptive functions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

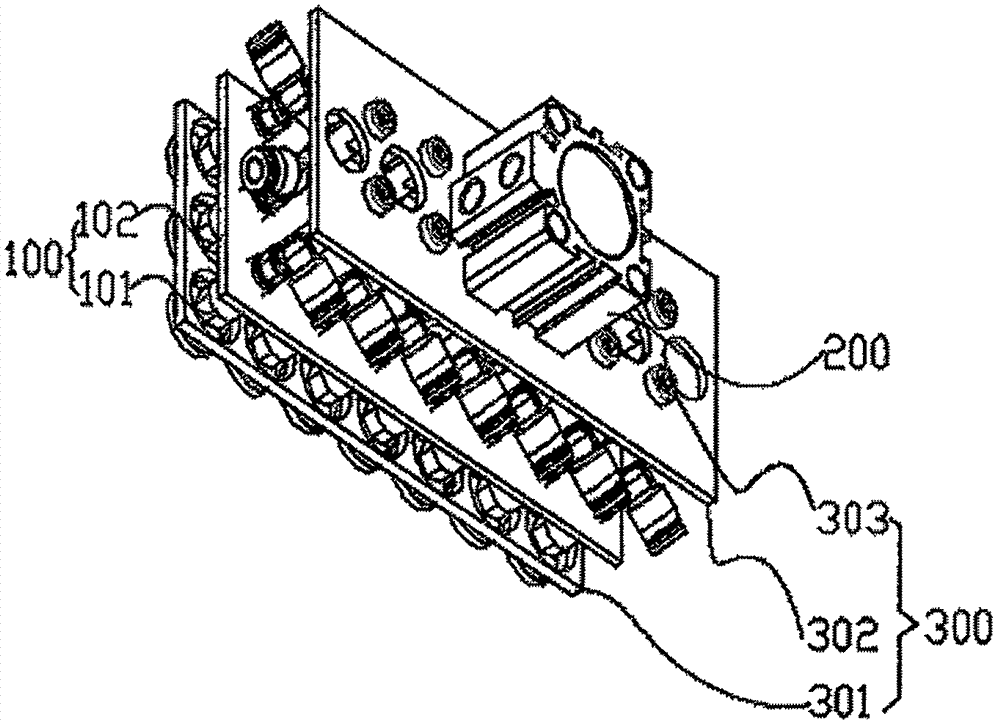

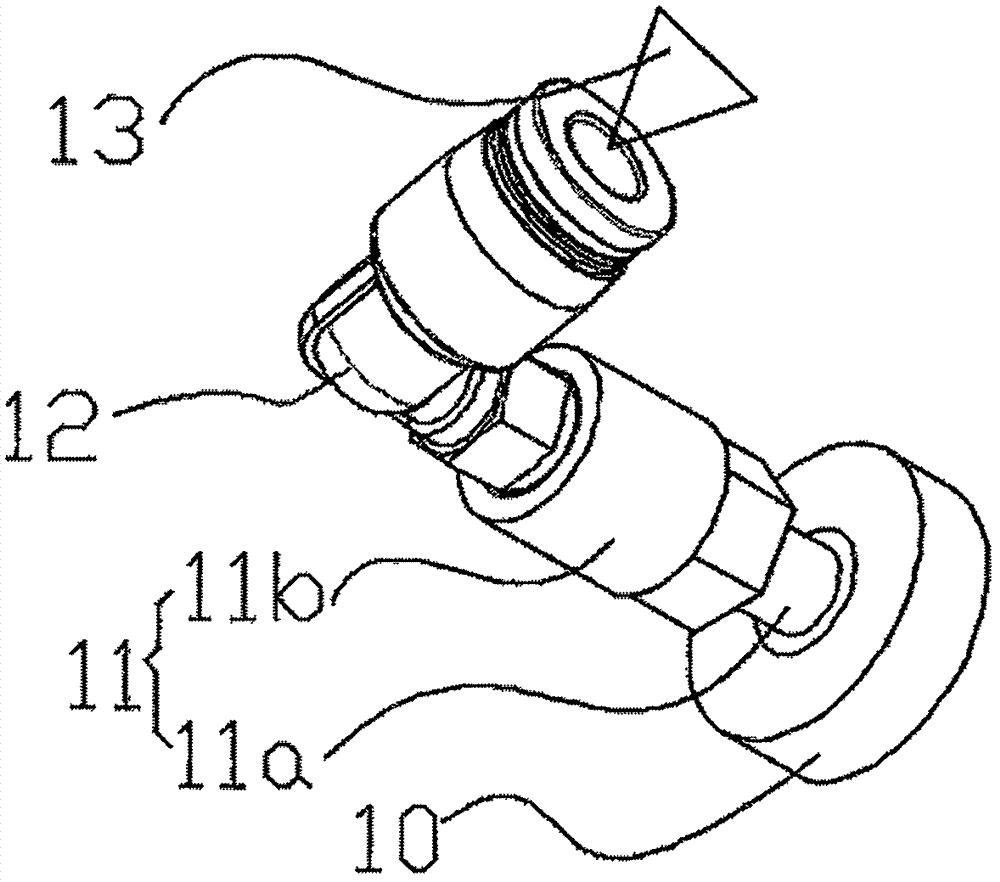

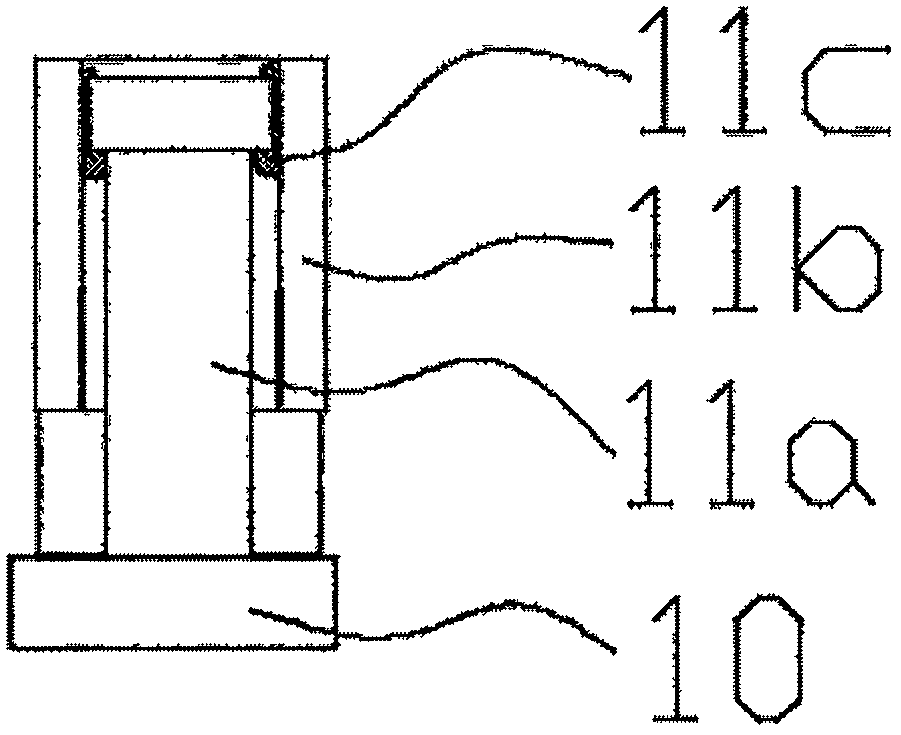

[0025] The invention proposes a magnetic chuck assembly with automatic adjustment and adaptation functions, which can automatically adapt to the adsorption surface of a workpiece. Such as Figure 1-5 As shown, the magnetic chuck assembly includes a suction device 100 , a drive device 200 and a part removal device 300 . Wherein, the stripping device 300 includes a rear stripping plate 301 , a rear fixing plate 302 and a front and rear plate connecting rod 303 . The driving device 200 is directly fixed on the stripping device 300, there is no relative movement between the two, and the two devices are directly fixed on the manipulator. The suction device 100 is composed of a plurality of execution units 101 and a fixing plate 102 . The number of execution units 101 installed on the fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com