Petroleum pipeline clamping and transporting device for improving transporting efficiency

A technology for oil pipelines and transportation efficiency, which is applied in the field of oil pipeline clamping transportation devices, which can solve the problems of low transportation efficiency and small number of oil pipelines, and achieve the effects of improving transportation efficiency, increasing the number of transportation, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

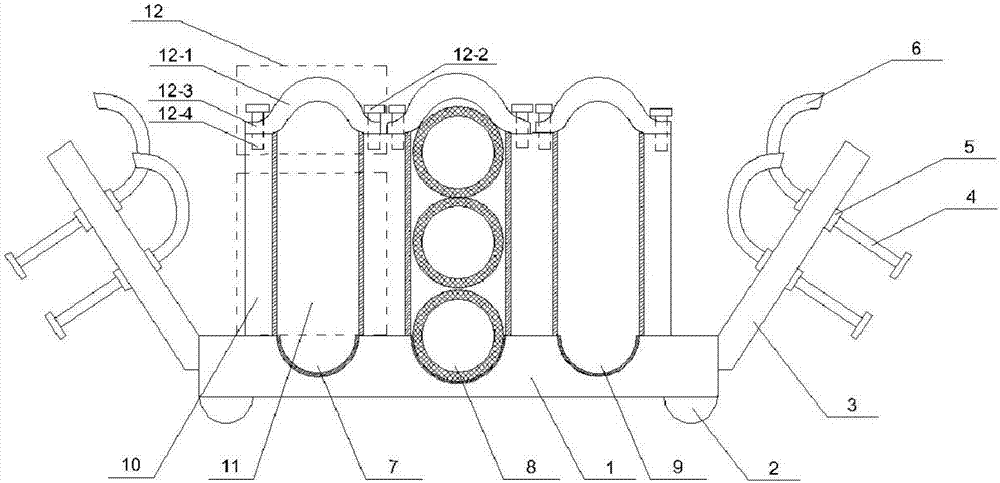

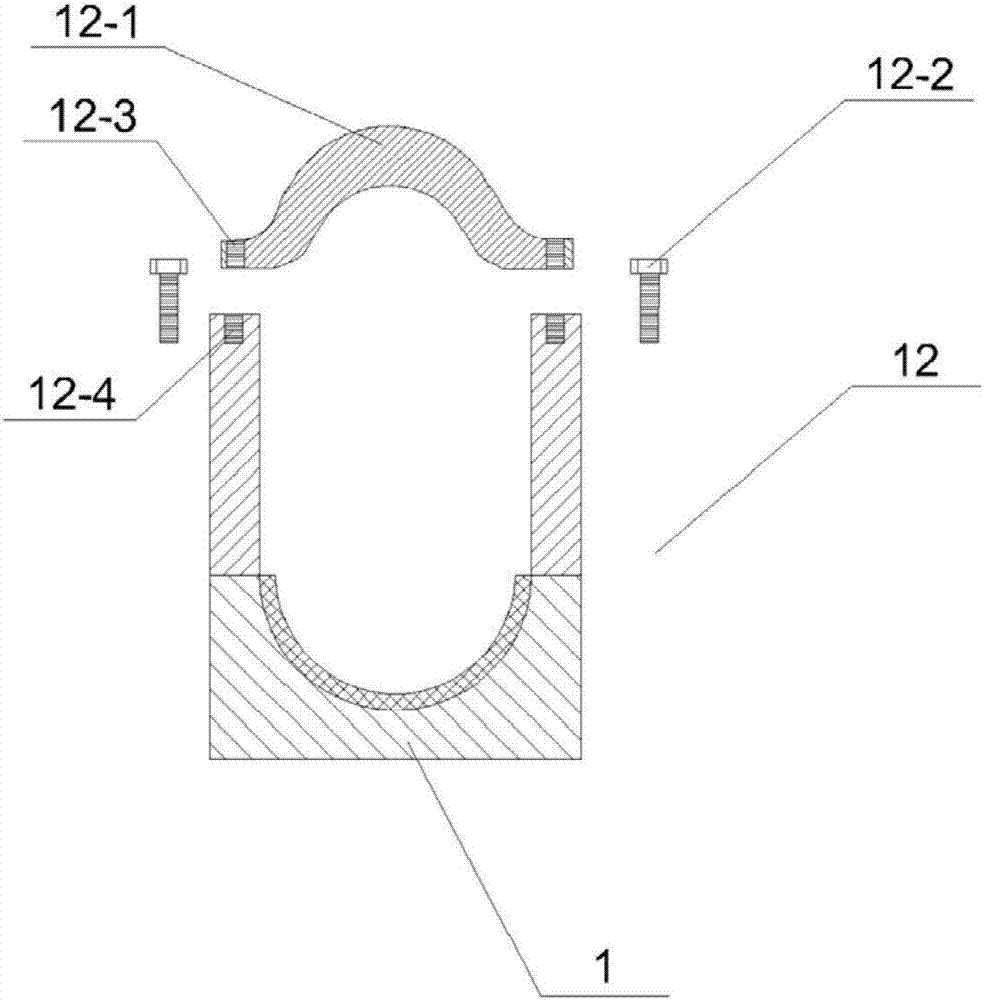

[0031] Such as figure 1 As shown, this embodiment provides a petroleum pipeline clamping transportation device that improves transportation efficiency, including a base 1, a moving roller 2 arranged at the lower end of the base 1, two side plates 3 symmetrically arranged on both sides of the base, vertically arranged on The screw rod 4 on the lower side of the side plate 3, the hoop 5 arranged on the upper and lower sides of the side plate 3 to fix the screw rod 4, and the arc-shaped clamping plate 6 arranged at the end of the screw rod 4 are characterized in that the base 1 is arranged in parallel and spaced apart Four blocking plates 10, the four blocking plates 10 divide the base 1 into three clamping areas 11, and the corresponding base areas in the three clamping areas 11 are respectively provided with semicircular grooves 7 and semicircular grooves. Groove two 8 and semicircular groove three 9, locking mechanisms 12 are provided at the tops of two adjacent blocking plate...

Embodiment 2

[0040] Such as Figure 1-2 As shown, this embodiment provides a petroleum pipeline clamping transportation device that improves transportation efficiency, including a base 1, a moving roller 2 arranged at the lower end of the base 1, two side plates 3 symmetrically arranged on both sides of the base, vertically arranged on The screw rod 4 on the lower side of the side plate 3, the hoop 5 arranged on the upper and lower sides of the side plate 3 to fix the screw rod 4, and the arc-shaped clamping plate 6 arranged at the end of the screw rod 4 are characterized in that the base 1 is arranged in parallel and spaced apart Four blocking plates 10, the four blocking plates 10 divide the base 1 into three clamping areas 11, and the corresponding base areas in the three clamping areas 11 are respectively provided with semicircular grooves 7 and semicircular grooves. Groove two 8 and semicircular groove three 9, locking mechanisms 12 are provided at the tops of two adjacent blocking pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com