Undercarriage test load loading device

A technology of loading device and landing gear, which is applied in the direction of aircraft component testing, etc., can solve the problems of unfavorable loading equipment installation, inability to apply load, etc., and achieve the effect of avoiding loading difficulties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

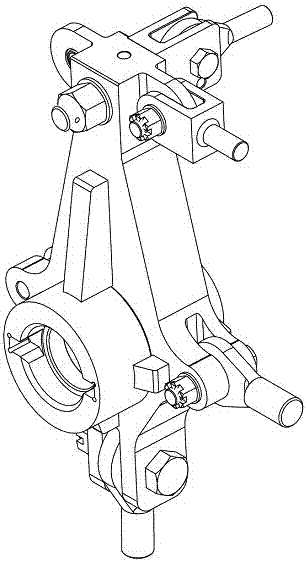

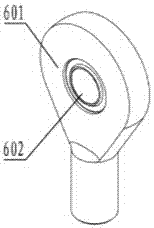

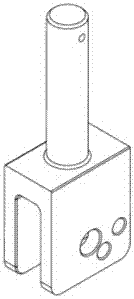

[0034] see Figure 1-14 A landing gear test load loading device, comprising a loading dummy wheel 1, a loading plate 101, a stiffener 102, a bushing 103, a FZ loading joint 2, an FZ loading lug 3, a first loading lug 301, a first joint bearing 302, FX loading joint 4, PX loading lug 5, second loading lug 501, second joint bearing 502, PY loading lug 6, third loading lug 601, third joint bearing 602, fastener 7, Force sensor 8, hydraulic servo actuator 9, column 10, landing gear 11, landing gear fixing fixture 12, chain 13, side load FZ of tire contact point, vertical load PY of wheel center, course load PX of wheel center, tire connection Point and heading load FX, when the aircraft landing gear fatigue test needs to apply load, apply the wheel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com