Convenient glass bottle with threaded opening and machining method

A glass bottle and screw mouth technology, applied in glass production, glass forming, glass manufacturing equipment, etc., can solve the problems of single screw mouth design, low strength of the screw mouth, inconvenient production and use, etc., to achieve beautiful structure, production and use. Convenience and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

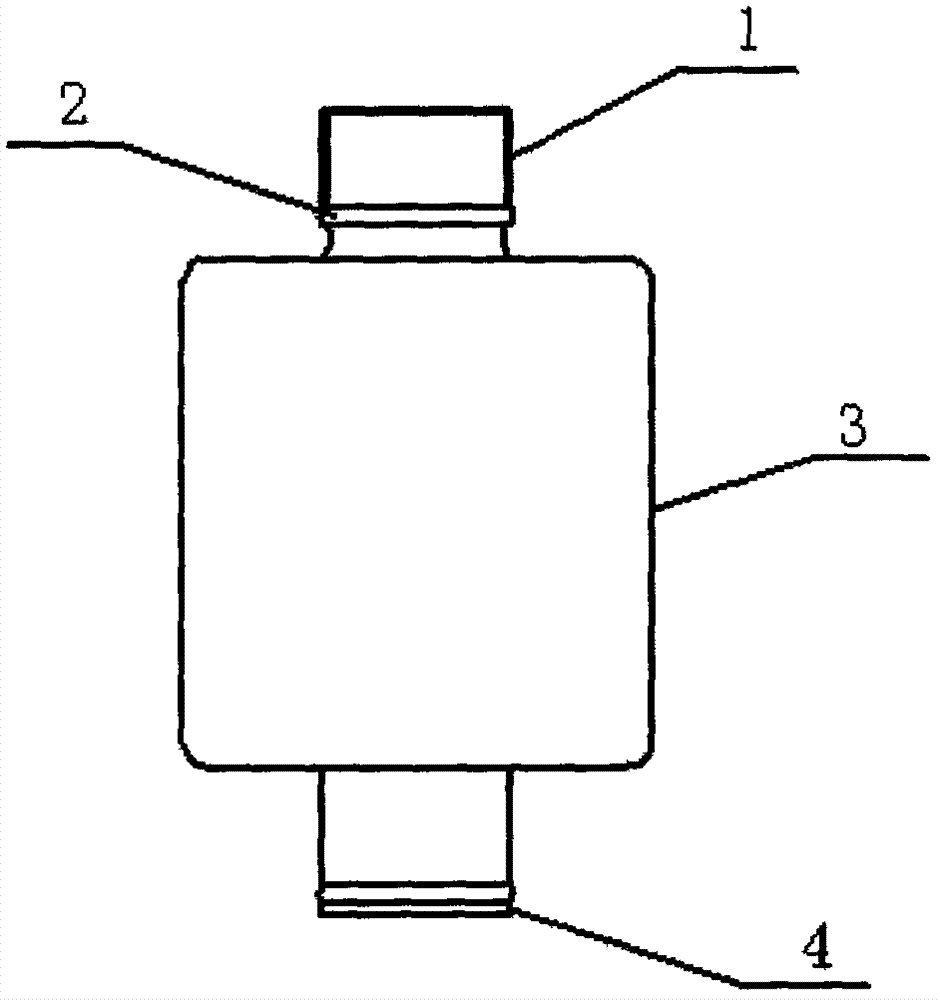

[0037] refer to figure 1 , is a glass bottle in the prior art, which is molded by one-time blowing of glass. The middle position is provided with a cylindrical hollow bottle body 3. On the same center line at both ends of the bottle body b3, two shapes are respectively set as bottle bodies 3 half of the diameter of the cylinder, the ends of the two cylinders are two bottlenecks, one end of the bottleneck is provided with a threaded end a1, a sealing ring 2 is set between the threaded end a1 and the bottle, and the other end of the cylinder is Bottle mouth end is provided with sealing seat 4.

Embodiment 2

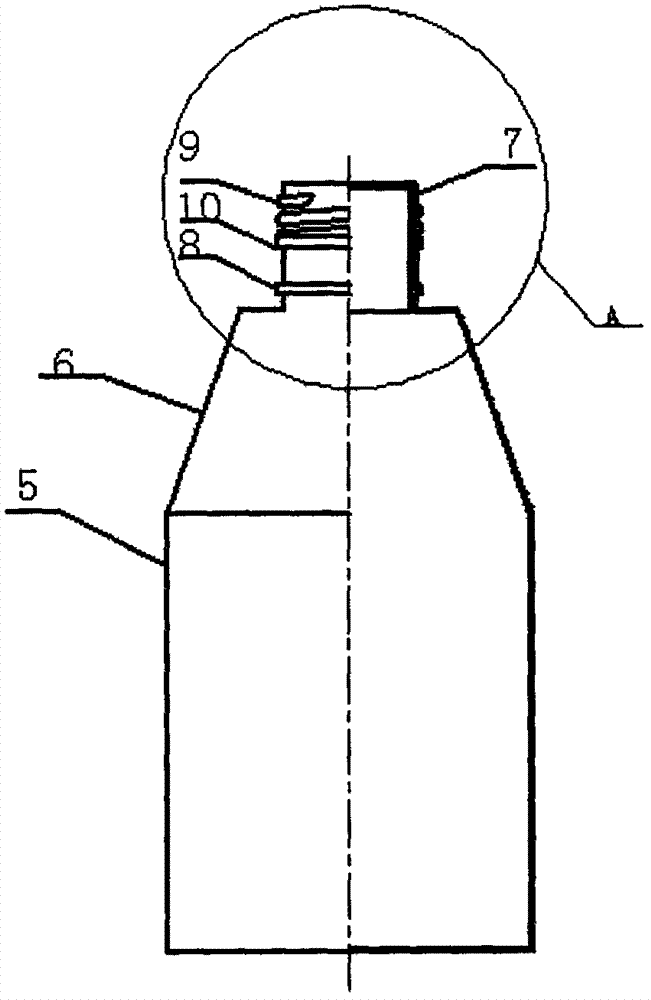

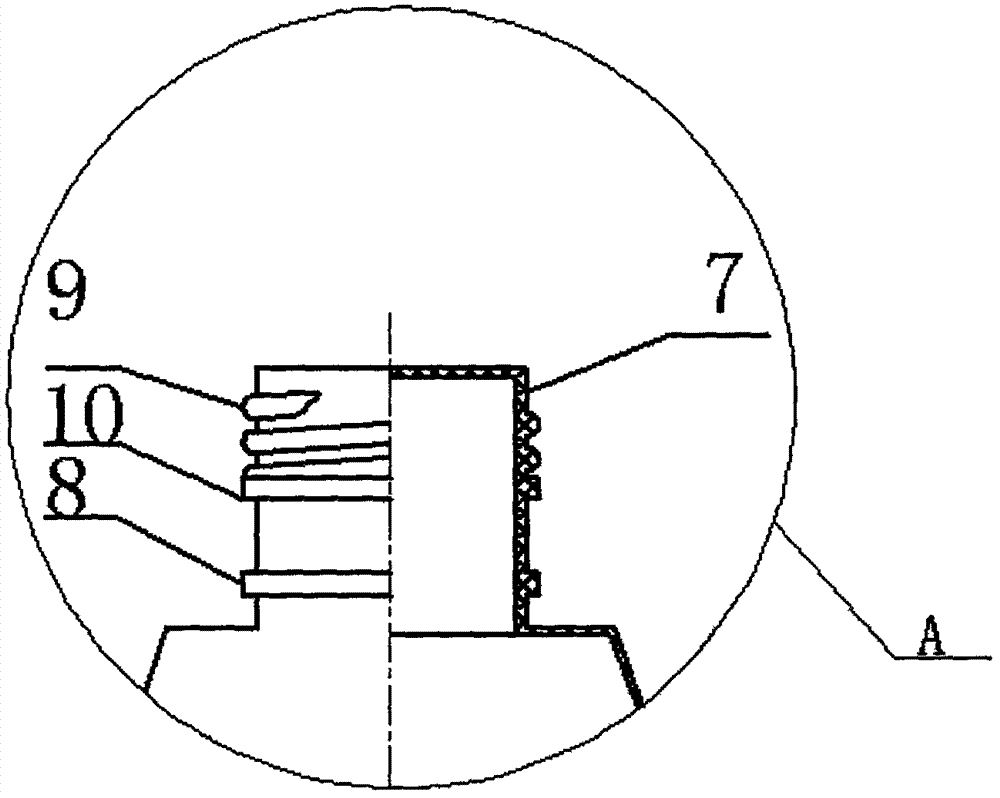

[0039] refer to figure 2 and image 3 , is the glass bottle with threaded mouth of the present invention, comprises bottle body 5, bottleneck 6 and bottleneck 7, and the cross-section of bottleneck 6 is truncated cone shape, and is that the lower end is big and the upper end is small, and the bottle mouth 7 is provided with near the bottle neck 6 side Bottleneck ring 8, bottle mouth 7 is positioned at the top of bottleneck ring 8 and is provided with threaded end 9, and threaded end 9 is external thread, and the length of threaded end 9 is set as two pitches, and the end of threaded end 9 is provided with sealing ring 10, bottle The outer diameter of the mouth 7 is smaller than the outer diameter of the smallest shrinkage mouth of the bottleneck 6, and the wall thickness of the bottleneck 7 is greater than the wall thickness of the bottle body 5. By being provided with a bottleneck ring 8, the bottleneck 7 is thickened, which increases the strength of the threaded mouth, and ...

Embodiment 3

[0041] A processing method for a glass bottle with a threaded mouth, which mainly includes the following steps: cutting: cutting a glass blank tube whose length is twice as long as the finished tube; Stretch slowly during the heating process until it breaks; then fix it on the mold and heat and form the bottom; threaded mouth forming: fix the glass blank tube prepared above on the threaded mouth forming equipment, and process and shape it; finished product packaging: put The processed glass bottle 11 with a threaded mouth is cleaned, air-dried, and finally packaged for storage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com