Loading box body device for diesel engine crankshafts

A diesel engine and box technology, applied in the field of mechanical devices, can solve problems such as accelerated wear of other parts, large vibration, and decreased precision of the crankshaft, and achieve the effect of avoiding collision and extrusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

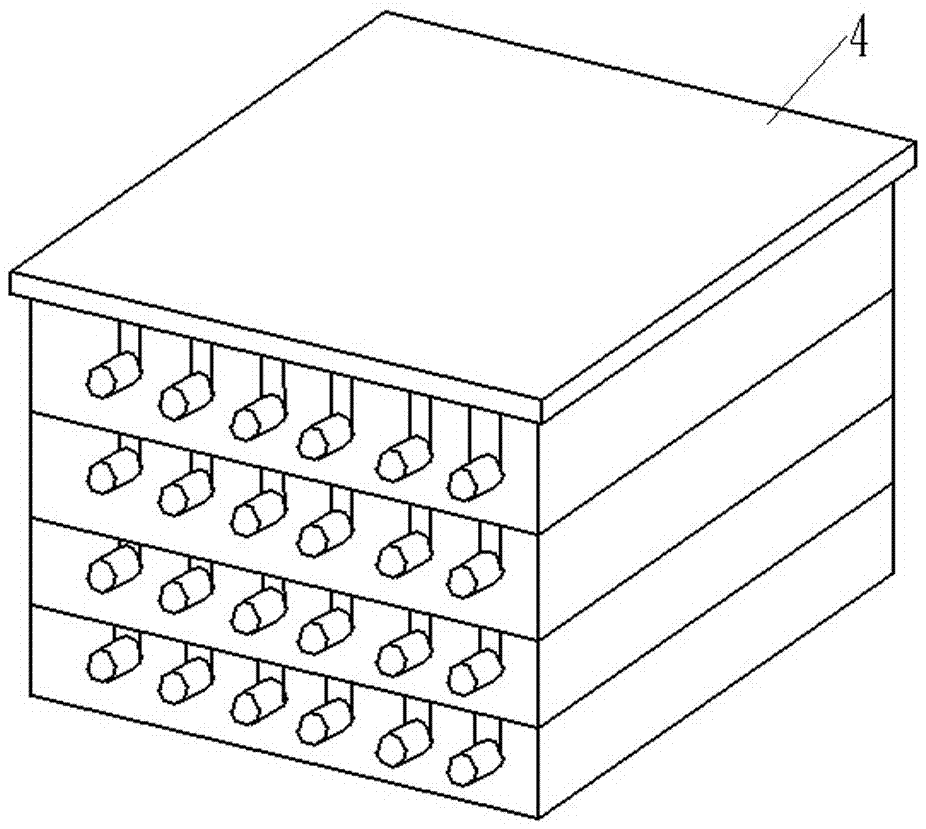

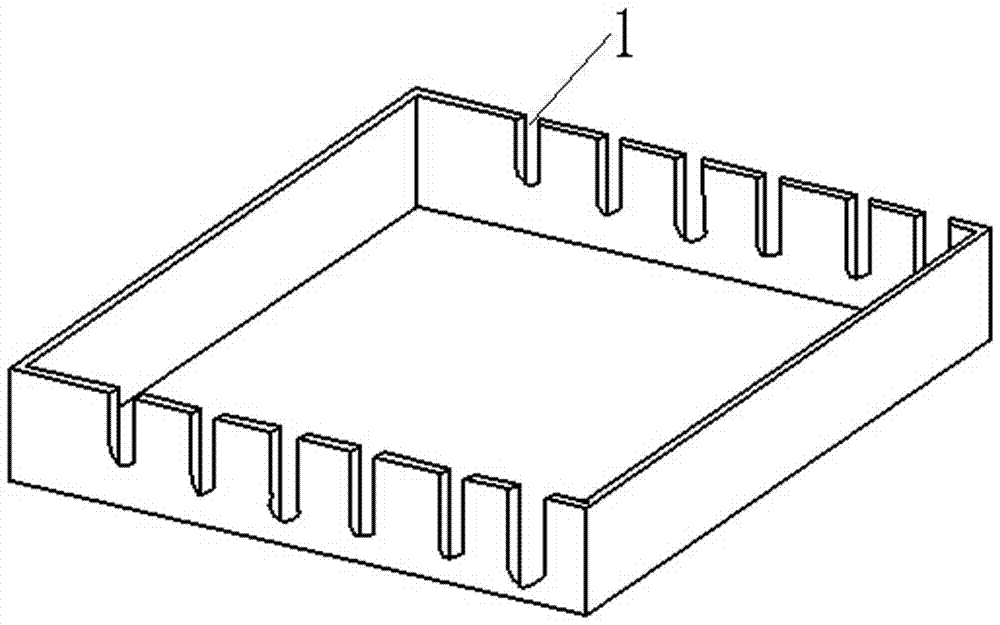

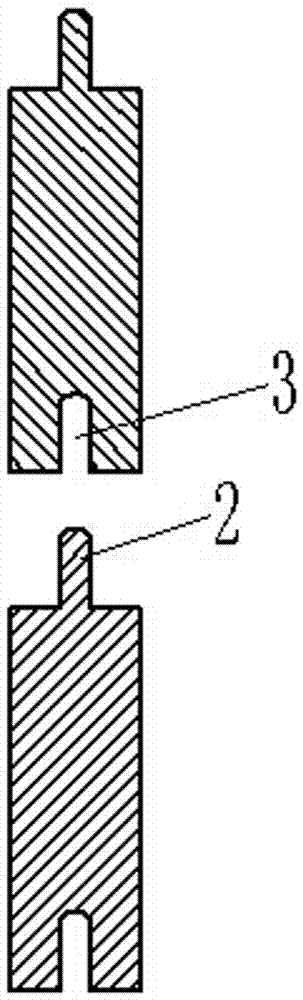

[0011] figure 1 , 2 , 3 middle: card slot 1, convex body 2, groove 3, upper cover 4.

[0012] A diesel engine crankshaft loading box device, the diesel engine crankshaft loading box device includes at least two box blocks, the box block is a rectangular frame stretching body, such as figure 2 shown. The box body block is provided with a card slot 1, the card slot 1 is opened upward, and the two card slots 1 correspond to each other, which is convenient for the clamping installation of the crankshaft. In the process of installing the crankshaft, only two positions at both ends need to be clamped. The corresponding card slots are filled in sequence, and the box blocks are accumulated and filled again to complete the boxing of all crankshafts. Finally, as shown in figure 1 shown.

[0013] The two ends of the central axis of the crankshaft are clamped in the card slot 1, and the upper edge of each of the box blocks is provided with a convex body 2, and the lower edge of each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com