External elastomer plastic cement spring pressing pump

An external and flexible technology, applied in the direction of spraying device, closing, packaging, etc., can solve the problems of pre-pressing, liquid leakage, rust-prone assembly, etc., to achieve the effect of convenient assembly and prevention of liquid leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings.

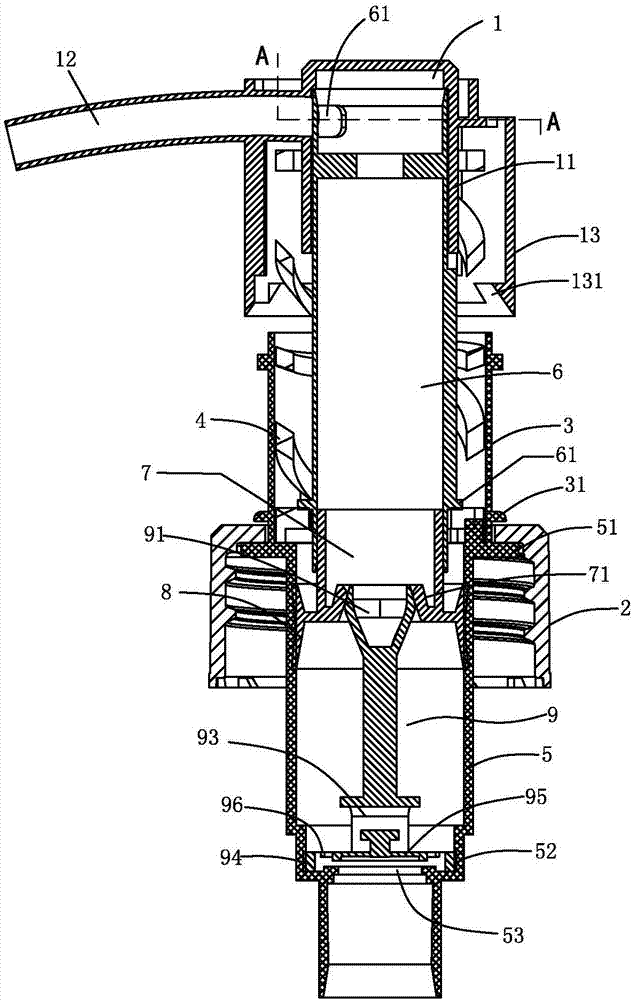

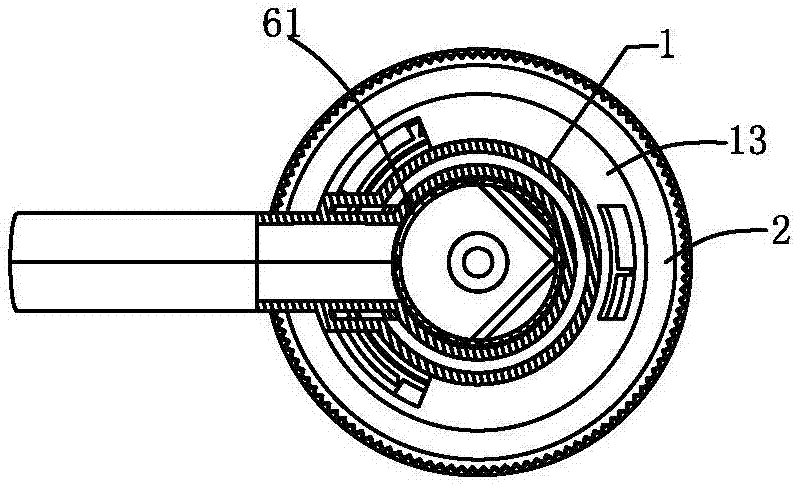

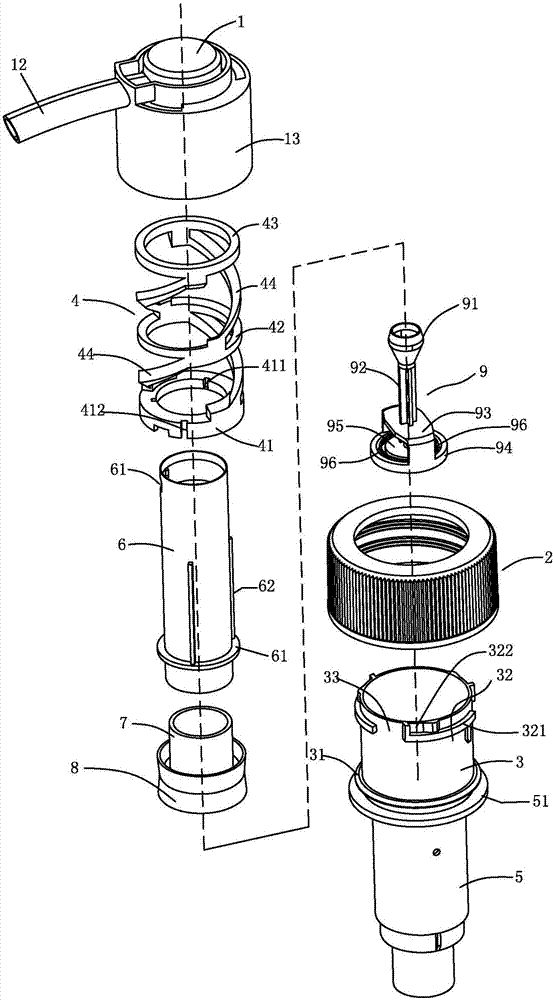

[0041] Such as figure 1 As shown, an external elastic body plastic spring press pump includes a press head 1, a thread 2, a lock cover 3, a spring 4, a body 5, a main post 6, an auxiliary post 7 and a piston 8, and the press head 1 includes a lower opening The body 11 and the liquid outlet pipe 12 communicating with the body; the press head 1 also includes a locking sleeve 13, and the lower end of the locking sleeve 13 is provided with a locking buckle 131;

[0042] The spring 4 is made of plastic material;

[0043] The upper end of the body 5 is provided with a flange 51, and the lower end of the body 5 is provided with a spool cavity 52 and a lower spool seat 53 located at the bottom of the spool cavity; the lock cover 3 is cylindrical, and the upper part is provided with a locking position 31 , The lower part is provided with a baffle 32, and the gap between two a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com