A method for realizing desulfurization of sodium sulfide-containing wastewater by using multi-acid ionic liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

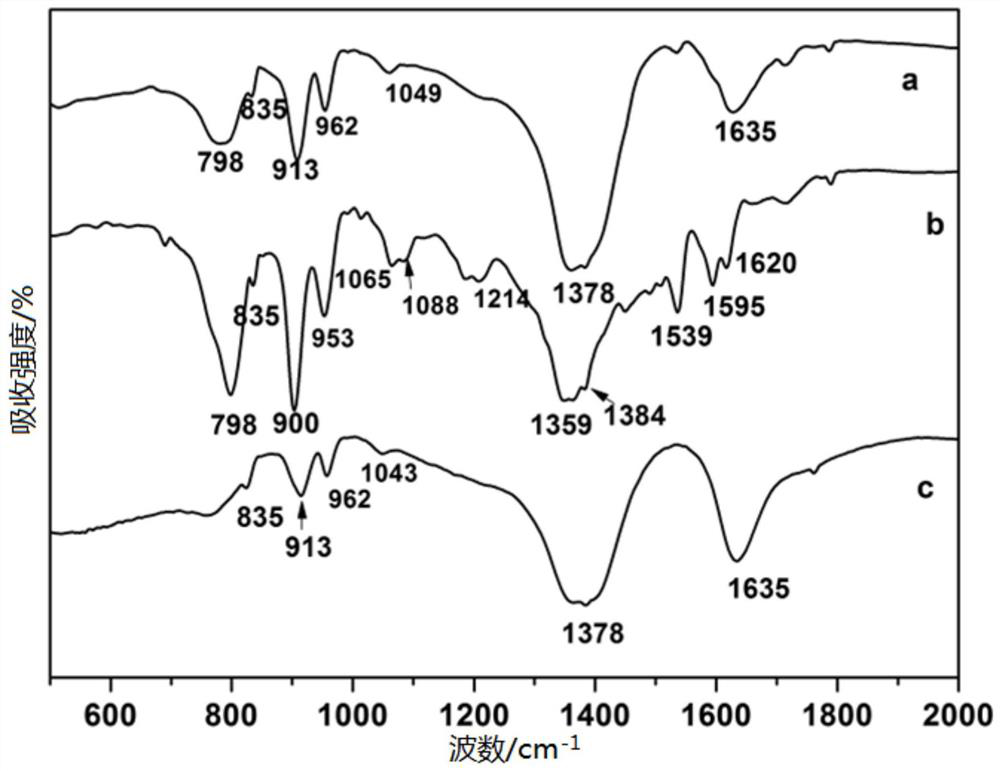

[0016] Specific embodiment one: This embodiment is a method for utilizing polyacid ionic liquids to realize the desulfurization of sodium sulfide-containing wastewater, specifically as follows:

[0017] Dissolving the polyacid ionic liquid in the medium solvent to obtain the polyacid ionic liquid medium solution, then adding the polyacid ionic liquid medium solution into the sodium sulfide-containing wastewater, stirring and reacting for 0.5h to 3h under light conditions, and filtering to obtain solid sulfur, That is to complete the desulfurization of sodium sulfide-containing wastewater; the mass of the polyacid ionic liquid and the volume ratio of the medium solvent is 4mg: (2 ~ 3) mL; sodium sulfide and polyacid ionic liquid medium solution The molar ratio of the polyacid ionic liquid is (8-10):1.

[0018] This embodiment uses the desulfurization method of multi-acid ionic liquid, which belongs to a new green and efficient desulfurization process of sodium sulfide-containin...

specific Embodiment approach 2

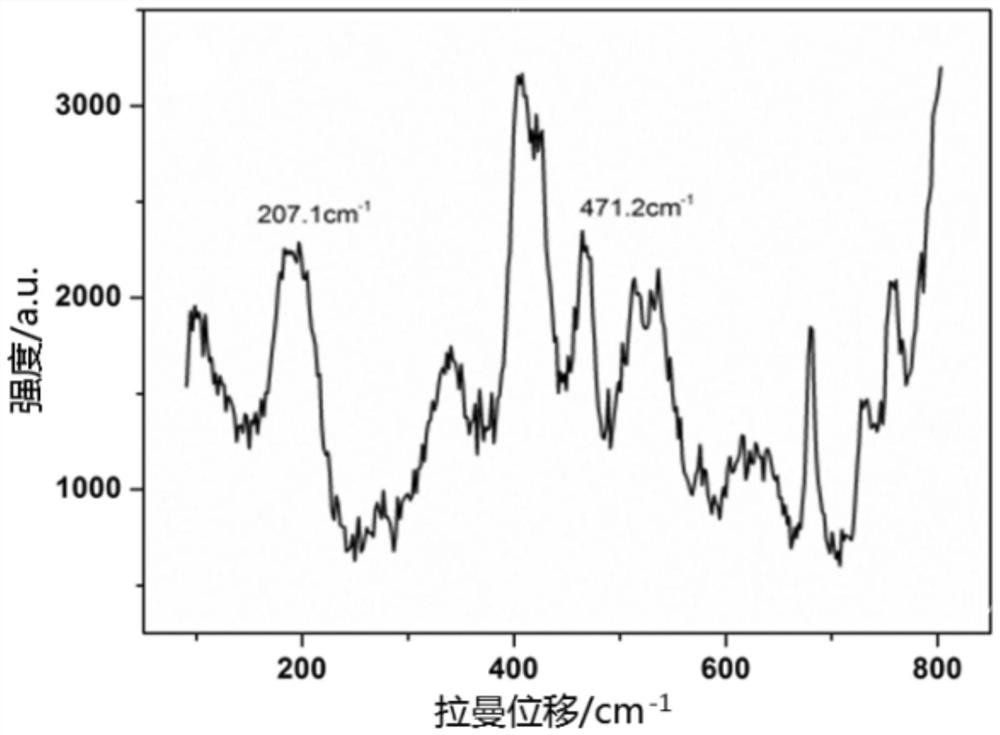

[0022] Specific embodiment two: the difference between this embodiment and specific embodiment one is: described polyacid ionic liquid is (C 33 h 32 N 3 ) 4 α-SiMo 12 o 40 , (C 33 h 32 N 3 ) 4 α-S 2 W 18 o 62 , (C 32 h 68 N) 4 α-S 2 W 18 o 62 or (C 32 h 68 N) 4 α-S 2 Mo 18 o 62 . Others are the same as the first embodiment.

[0023] when (C 33 h 32 N 3 ) 4 α-SiMo 12 o 40 When used as a multi-acid ionic liquid, the reaction mechanism is as follows:

[0024] SiMo 12 VI o 40 4- +S 2- →SiMo 10 VI Mo 2 V o 40 6- +S↓

[0025] SiMo 10 VI Mo 2 V o 40 6- +S 2- →SiMo 8 VI Mo 4 V o 40 8- +S↓

[0026] SiMo 8 VI Mo 4 V o 40 8- +S 2- →SiMo 6 VI Mo 6 V o 40 10- +S↓

[0027] SiMo 6 VI Mo 6 V o 40 10- +S 2- →SiMo 4 VI Mo 8 V o 40 12- +S↓

[0028] SiMo 4 VI Mo 8 V o 40 12- +S 2- →SiMo 2 VI Mo 10 V o 40 14- +S↓

[0029] SiMo 2 VI Mo 10 V o 4014- +S 2- →SiMo 12 V o 40 16- +S↓

[0030] SiMo...

specific Embodiment approach 3

[0102] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the medium solvent is water, ethanol medium solvent or acetonitrile medium solvent, and the ethanol medium solvent is ethanol / water solution, and ethanol / water solution It is formed by mixing ethanol and water at a volume ratio of 1:1; the acetonitrile medium solvent is acetonitrile / water solution, and the acetonitrile / water solution is formed by mixing acetonitrile and water at a volume ratio of 1:1. Others are the same as those in Embodiment 1 or 2.

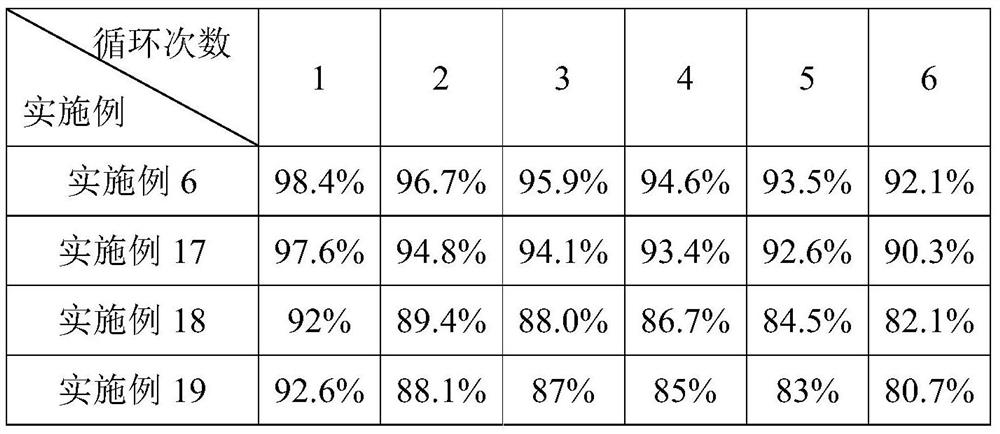

[0103] When the medium solvent is water: regeneration method Ⅰ

[0104] To the filtrate obtained by filtering in this embodiment, add 30% hydrogen peroxide by mass fraction or directly feed air for 20min to 50min, the volume ratio of 30% hydrogen peroxide to medium solvent (water) by mass fraction is 1:1, complete The recovery of the ionic liquid-aqueous medium solvent is completed.

[0105] When the medium solvent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com