Support systems, modularized tents, modularized tent set and draining method of modularized tent set

A bracket system and modular technology, applied in the field of tents, can solve the problems of not being able to realize close side by side, not having a drainage system, and not being able to realize modular splicing, etc., so as to achieve the effect of improving the use performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

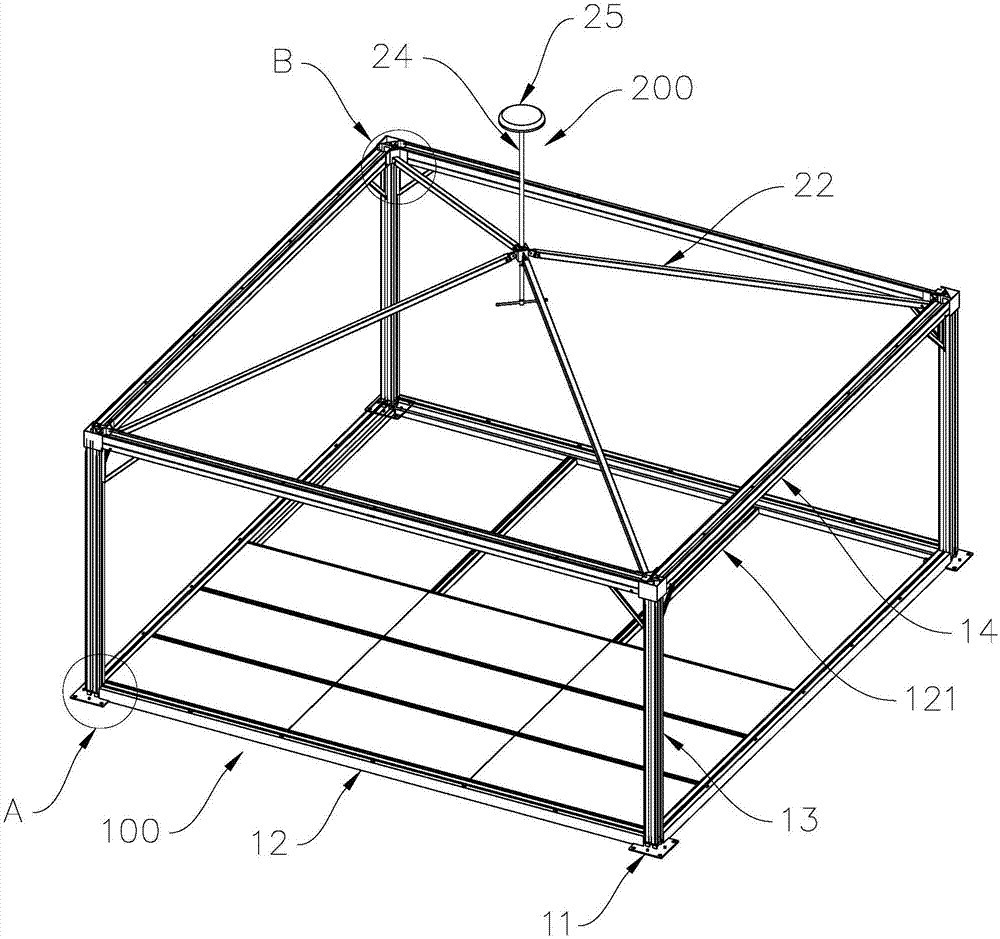

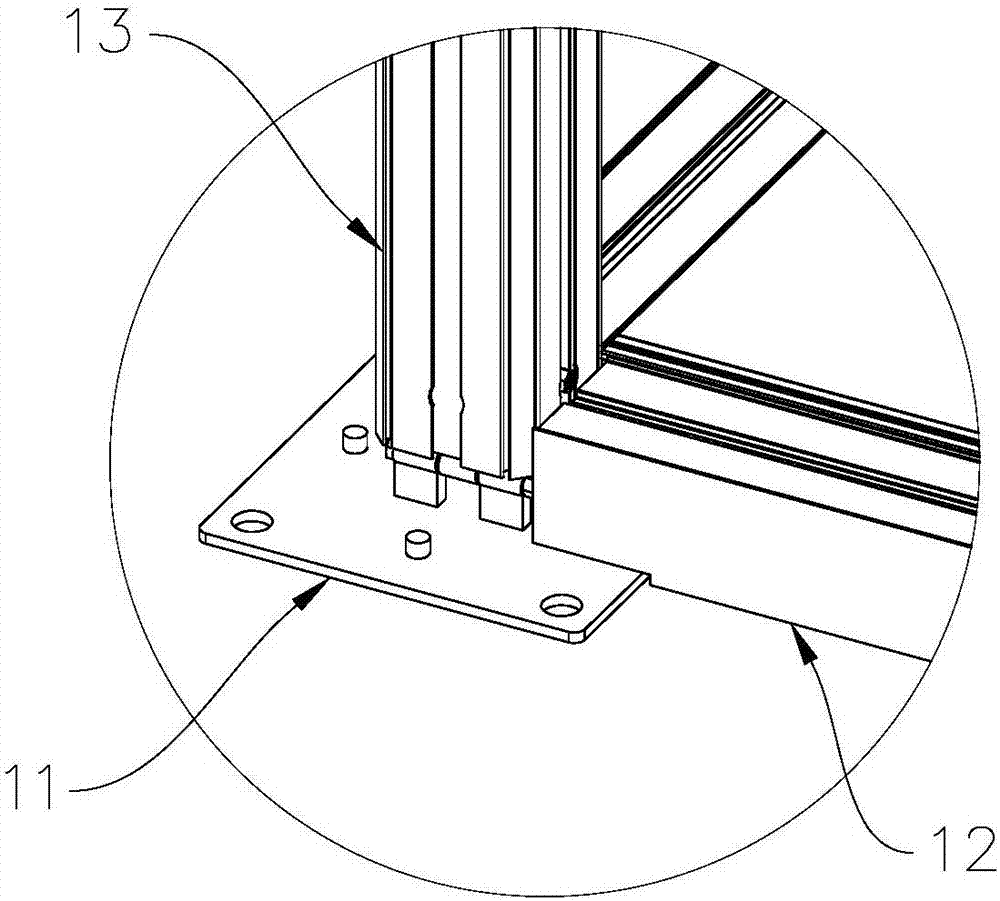

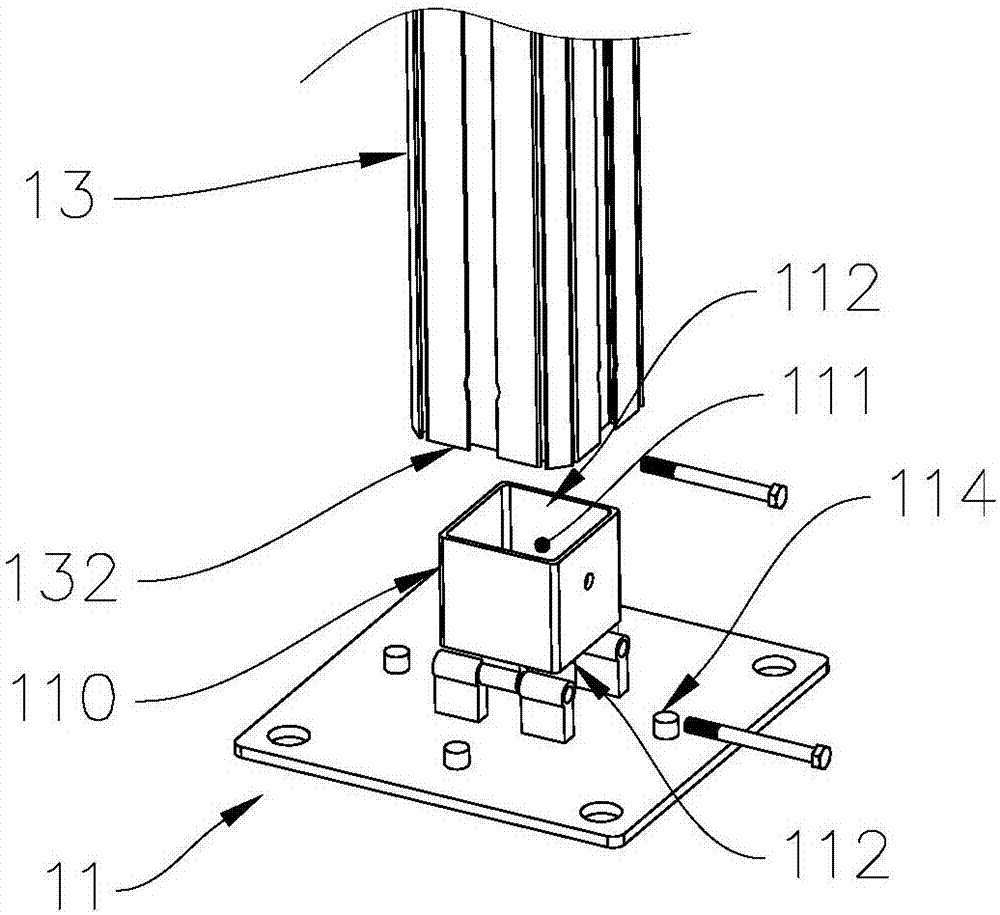

[0044] see figure 1 , figure 1It is a structural diagram of the support system 100 in the first embodiment of the modular tent of the present invention. The modular tent includes a bracket system 100 , a wall unit (not shown in the figure), a floor unit and a tarpaulin (not shown in the figure) arranged on the upper end of the bracket system 100 . The bracket system 100 includes a base 11, a bottom beam 12, a column 13, a beam 14 and a top bracket assembly 200, the base 11 is fixed on the ground, the bottom beam 12 is connected between the two bases 11, the column 13 is installed on the base 11, and the beam 14 is connected between the upper ends of two columns 13 , and the beam 14 is parallel to the bottom beam 12 . The wall unit is arranged between the beam and the bottom beam, the floor unit is supported on the bottom beam 12 and the secondary bottom beam 121 , the edge of the tarpaulin is fixedly connected to the beam 14 , and the tarpaulin is supported by the top bracke...

no. 3 example

[0057] see Figure 13 , Figure 14 and Figure 15 , Figure 13 It is a structural diagram of the bracket system in the third embodiment of the modular tent of the present invention, Figure 14 for Figure 13 The magnified view at E in the middle, Figure 15 It is the working principle diagram of the third embodiment of the modular tent of the present invention. Since the bracket system 5 in this embodiment is completely the same as that in the first embodiment, it will not be described in detail. The top bracket assembly 6 includes a connecting plate 61 and a steel cable 62 . The connecting plate 61 is connected between two adjacent beams 54, and the connecting plate 61 is close to the column 53; the modular tent includes four columns 53 arranged in a rectangular array, and each column 53 is provided with a back against it A connecting plate 61 , a steel cable 62 is connected between the two connecting plates 61 corresponding to the two columns 53 arranged diagonally, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com