A water pump

A water pump and water cut-off technology, which is applied in the direction of pumps, pump components, variable-capacity pump components, etc., can solve the problems of poor water sealing and large vibration at the water sealing port, and achieve the effects of low cost, slow movement, and ensuring tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

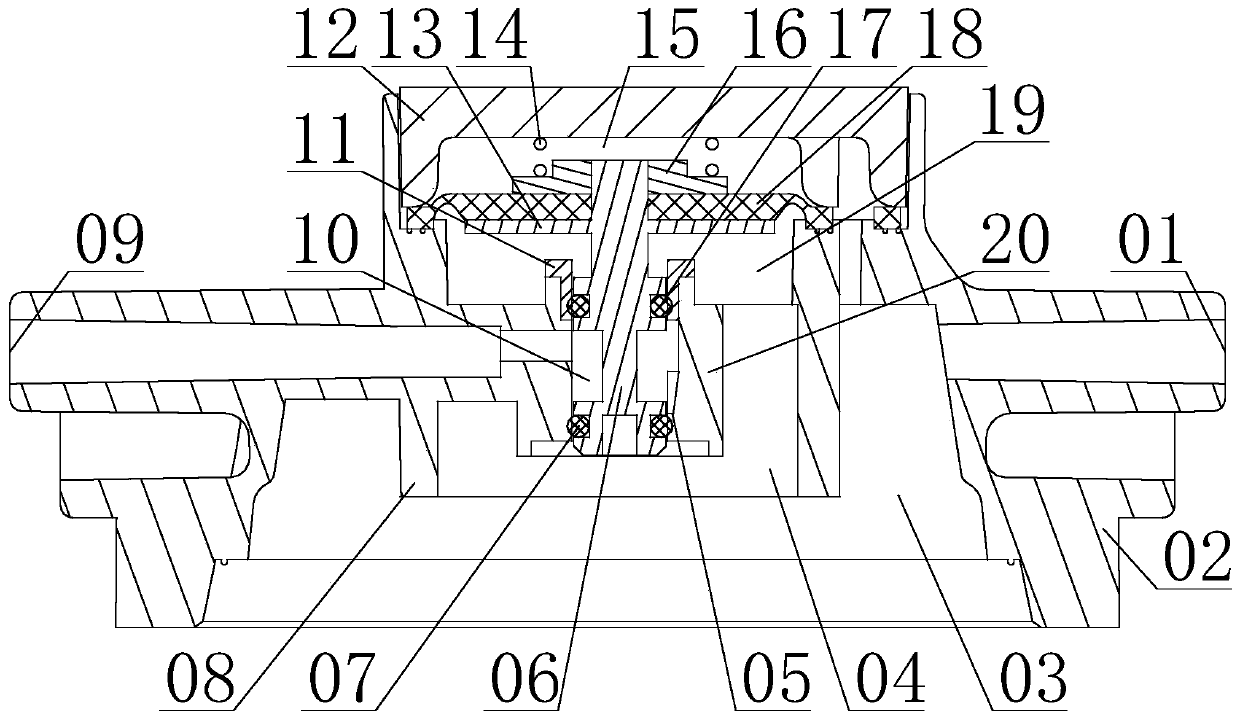

[0025] Such as figure 1 As shown, a water cut-off pump includes a pump body and a water cut-off assembly arranged in the pump body, wherein the pump body includes a pump head body 02 and an upper cover 12, and the pump head body 02 is composed of a water inlet 01, a sealing ring sleeve 08, an outlet Water port 09, water sealing sleeve 1 20, and raw water chamber 1 03 and water outlet chamber 1 04 which are sequentially arranged on the connection channel from water inlet 01 to water outlet 09, raw water chamber 1 03 and water outlet chamber 1 04 are covered by a sealing ring 08 separate composition. In this embodiment, the upper cover 12 is sealingly connected with the top of the pump head body 02 and forms a housing cavity with the pump head body 02. The water cut-off component separates the housing cavity to form two upper and lower cavities, and the lower cavity is The water outlet chamber three 19 connected with the water outlet chamber one 04, and the cavity above is the ...

Embodiment 2

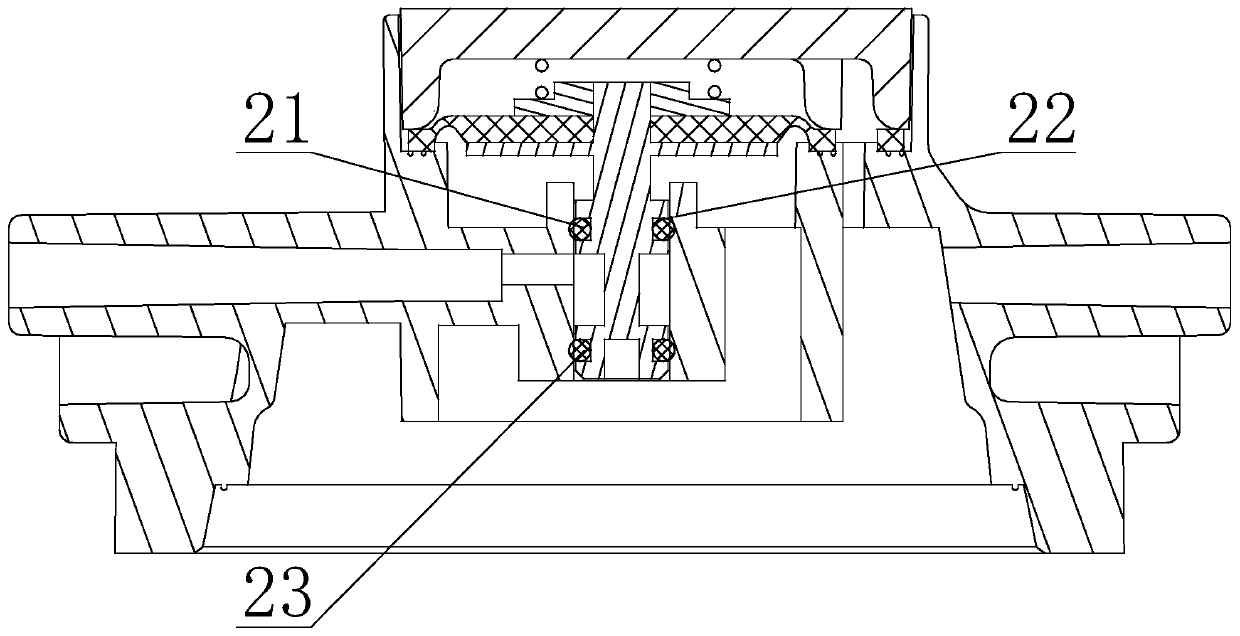

[0031] Such as figure 2 As shown, the difference between this embodiment and Embodiment 1 is that the water sealing port of this embodiment is the water sealing port 2 22 formed by the opening of the upper end of the water sealing sleeve 1 20, and the two sleeves set on the control rod 1 06 of this embodiment The sealing rings are respectively the water sealing ring 2 21 located on the upper side of the water inlet chamber 10 and the sealing ring 2 23 located on the lower side of the water inlet chamber 10 .

[0032] When this embodiment is applied, the water sealing ring 2 21 is embedded in the water outlet cavity 3 19 when the sealing water port 22 is opened, and the water sealing ring 2 21 is sealed with the inner wall of the upper opening of the water sealing sleeve 1 20 when the sealing water port 2 22 is closed. touch.

Embodiment 3

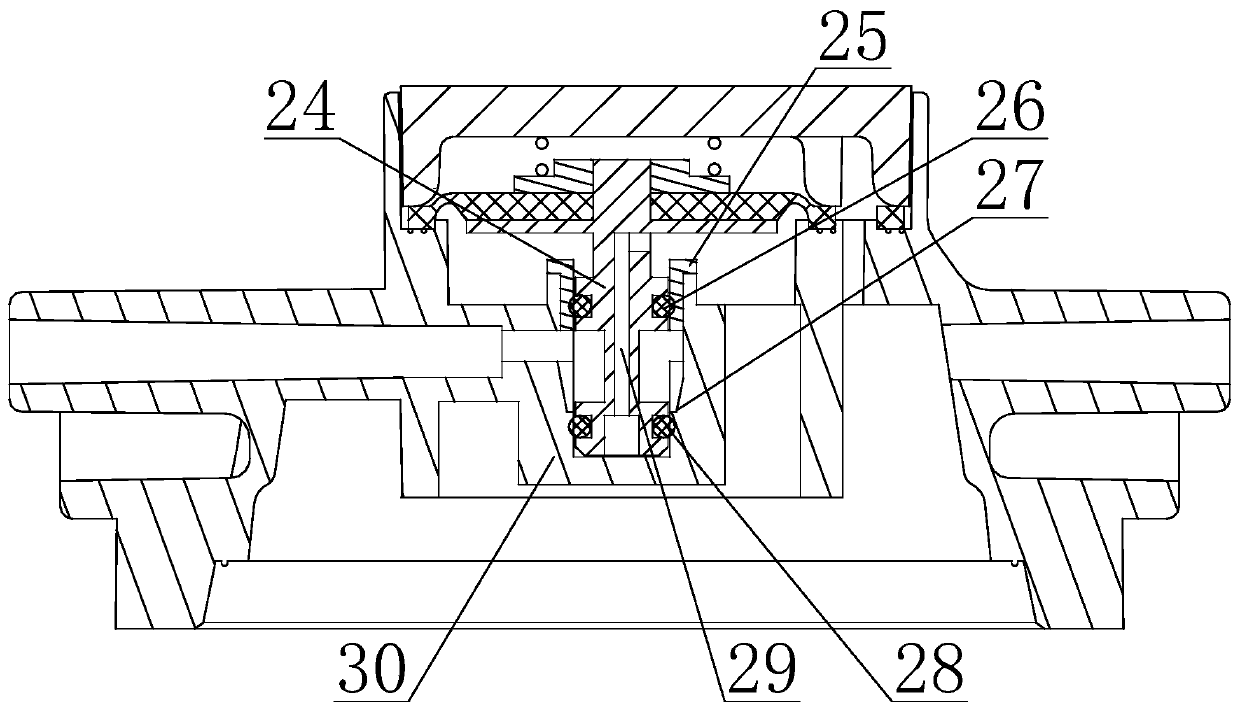

[0034] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that the water sealing sleeve of this embodiment is the water sealing sleeve 2 30 with the lower end sealed, the control rod is the control rod 2 24 forming a water passage 29, and the water sealing The part of sleeve two 30 located above the water inlet chamber two 10 is replaced by the auxiliary sealing ring sleeve one 11 by the auxiliary sealing ring sleeve two 25, and the water sealing port is set on the water sealing sleeve two 30 and located at the water outlet chamber two The water sealing port 3 27 at the bottom of 10, and the two sealing rings set on the control rod 2 24 are the sealing ring 3 26 on the upper side of the water inlet chamber 10 and the water sealing ring located on the lower side of the water inlet chamber 2 10 Three 28.

[0035] In this embodiment, the lower end of the control rod two 24 is embedded in the water sealing sleeve two 30 and a damping chamber is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com