Judging method and judging system for size of electromagnetic oven cooker as well as electromagnetic oven

A technology of pot size and induction cooker, applied in the field of induction cooker, can solve the problems of easy to cause misjudgment, low resolution, low accuracy of judgment results, etc., and achieve the effect of prolonging service life and increasing safety performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

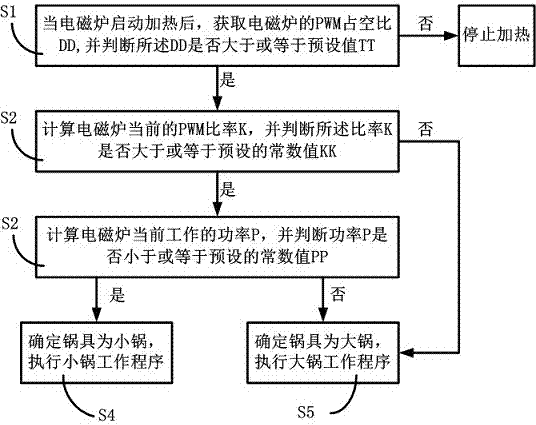

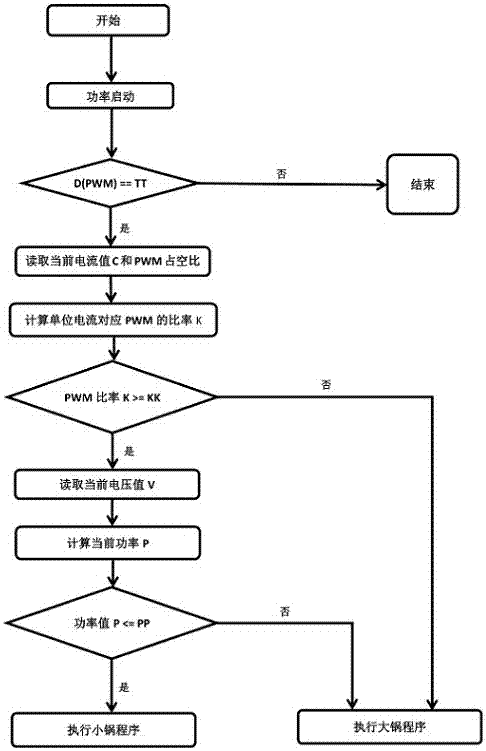

[0034] A method for judging the size of an electromagnetic cooker pan, as attached figure 1 As shown, the steps of the judging method include:

[0035] S1. After the induction cooker starts heating, obtain the PWM duty cycle DD of the induction cooker, and judge whether the DD is greater than or equal to the preset value TT, and if so, enter step S2;

[0036] S2. Calculate the current PWM ratio K of the induction cooker, and judge whether the ratio K is greater than or equal to the preset constant value KK, if so, enter step S3, otherwise go to step S5;

[0037] S3. Calculate the current working power P of the induction cooker, and judge whether the power P is less than or equal to the preset constant value PP, if so, go to step S4, otherwise go to step S5;

[0038] S4. Determine that the pot is a small pot, and execute the small pot working procedure;

[0039] S5. Determine that the pot is a large pot, and execute a large pot working procedure.

[0040] As a preferred embo...

Embodiment 2

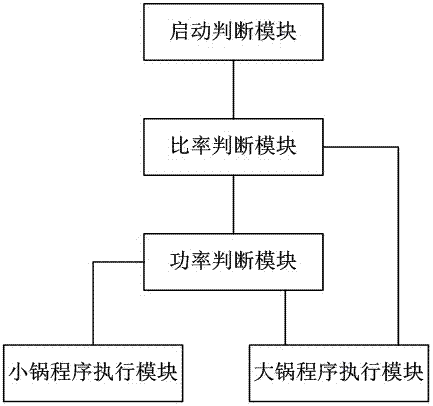

[0057] Based on the inventive concept of the above-mentioned embodiment 1, this embodiment provides a judging system for the size of an induction cooker pan, as shown in the attached image 3 As shown, the judgment system includes:

[0058] The start judgment module is used to obtain the PWM duty cycle DD of the induction cooker after the induction cooker starts heating, and judge whether the DD is greater than or equal to the preset value TT, and if the judgment result is yes, then open the ratio judgment module; as a preference, When it is determined that the DD is less than the preset value TT, the induction cooker stops heating;

[0059] The ratio judging module is used to calculate the current PWM ratio K of the induction cooker, and judge whether the ratio K is greater than or equal to the preset constant value KK, if so, turn on the second calculation and power judging module, otherwise turn on the cauldron program execution module ;

[0060] The power judging module ...

Embodiment 3

[0067] Based on the inventive concepts of Embodiment 1 and Embodiment 2 above, this embodiment provides an induction cooker, which includes the judging system as described in Embodiment 2.

[0068] In one of the preferred embodiments, the induction cooker includes an AC input module 1, an EMC filter module 4, a first rectification module 5, an LC oscillation module 6, a synchronous sampling module 10 and a main control module 11 connected in sequence. The AC input module 1 is connected to the main control module 11 through the second rectification module 2 and the switching current module 3 in turn, the first rectification module 5 is connected to the main control module 11 through the current sampling module 7, and the second rectification module 2 is connected to the main control module 11 through the voltage sampling module 8, the main control module 11 is connected to the LC oscillation module 6 through the IGBT drive module 9, and the EMC filter module 4 is also connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com