High-efficiency range hood with flue gas buffering and trapping functions

A range hood, high-efficiency technology, applied in the field of oil fume treatment devices, can solve the problems of high concentration of oil pollution, large amount of oil fume gas generation, blockage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions of the present invention will be further described in detail below in conjunction with specific embodiments.

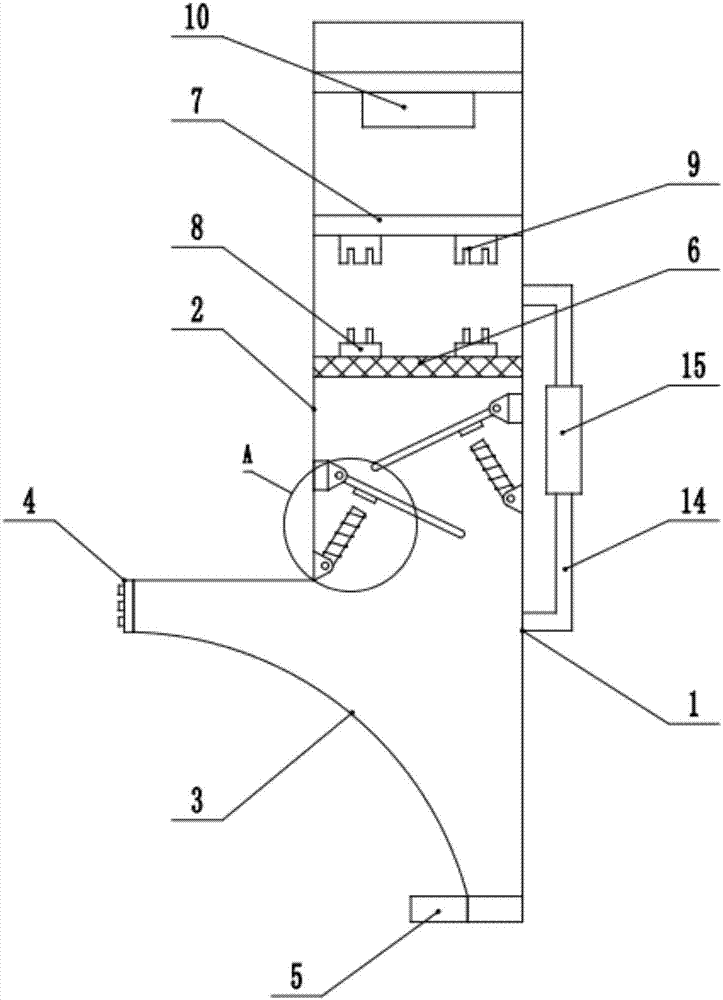

[0018] see Figure 1-2 , a high-efficiency range hood for flue gas buffering and interception, comprising a range hood body 1; the range hood body 1 is mainly composed of an exhaust pipe 2 and a range hood 3; The pipeline 2 is connected, and the surface of the oil suction hood 3 is fixedly connected with a control panel 4, and the control panel 4 is provided with a plurality of operation keys, and the bottom of the oil suction hood 3 is fixedly connected with an oil storage tank 5, and the oil storage tank 5 is used to store the oil fume gas passing through Oil stains that are intercepted during the oil suction hood 3.

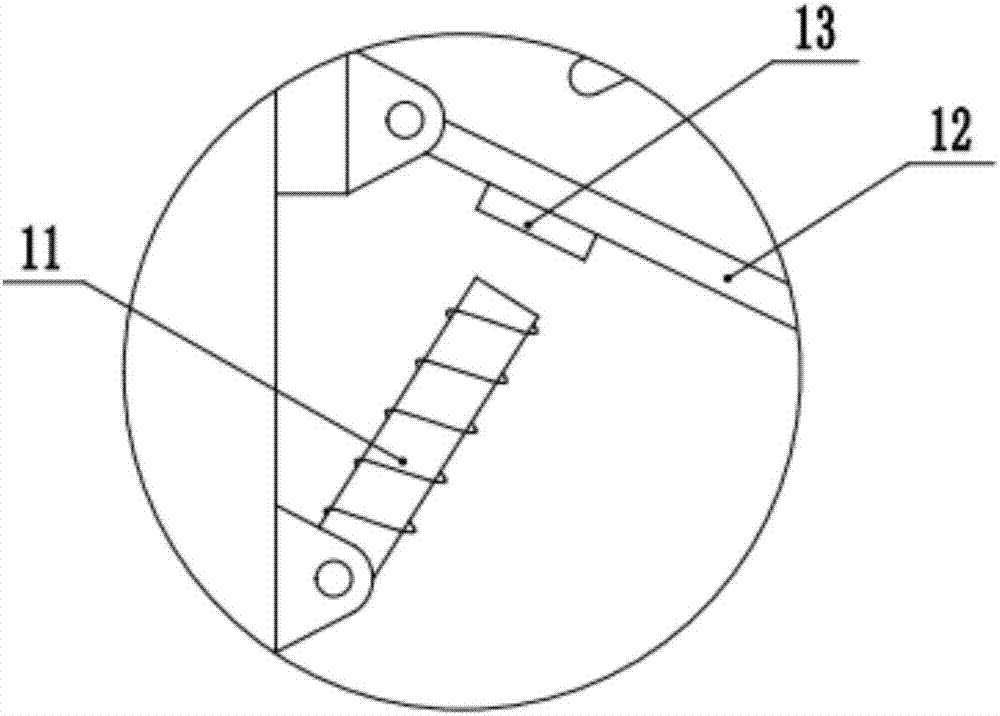

[0019] A buffer plate 12 is hinged on the inner wall of the exhaust pipe 2, and an electromagnet 11 is fixedly connected to the inner wall of the exhaust pipe 2. The electromagnet 11 is electrically connected to the pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com