Automatic tracking emitter

An automatic tracking and projectile technology, applied in the direction of projectiles, offensive equipment, weapon types, etc., can solve the problems of projectiles not being able to track targets and low strike accuracy, and achieve optimal spatial layout, improve strike accuracy, and improve tracking capabilities Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

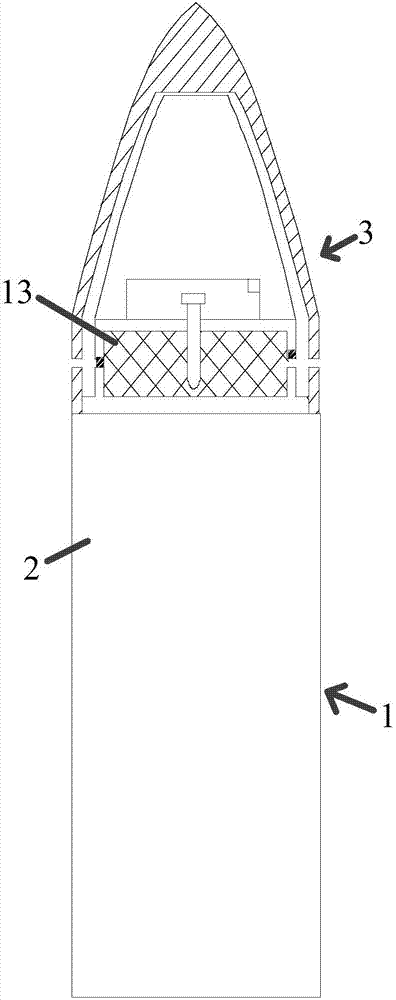

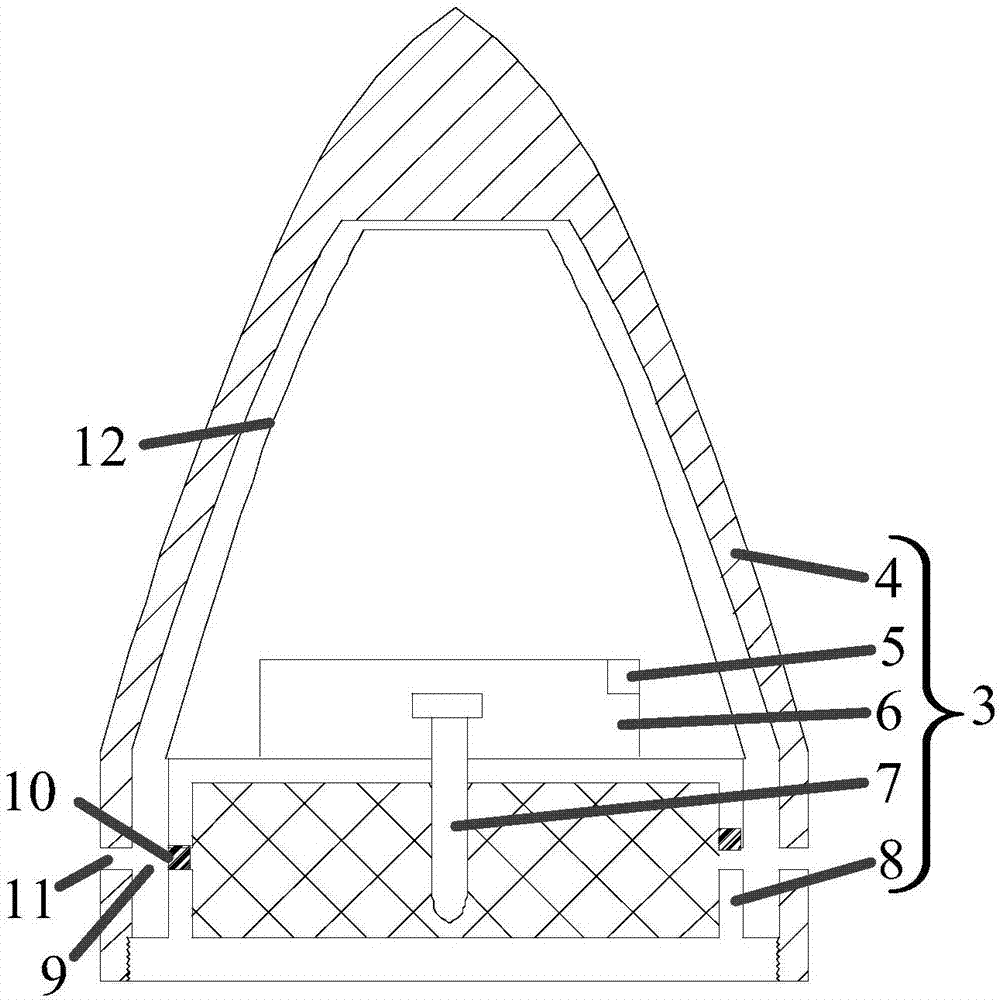

[0042] Such as figure 1 with figure 2 The auto-tracking projectile shown is a bullet, which consists of:

[0043] The signal transmitter is pre-set on the tracked target and is used to transmit position signals;

[0044] The projectile body 1 is provided with a primary motive medium 2 in the inner cavity of the projectile body 1;

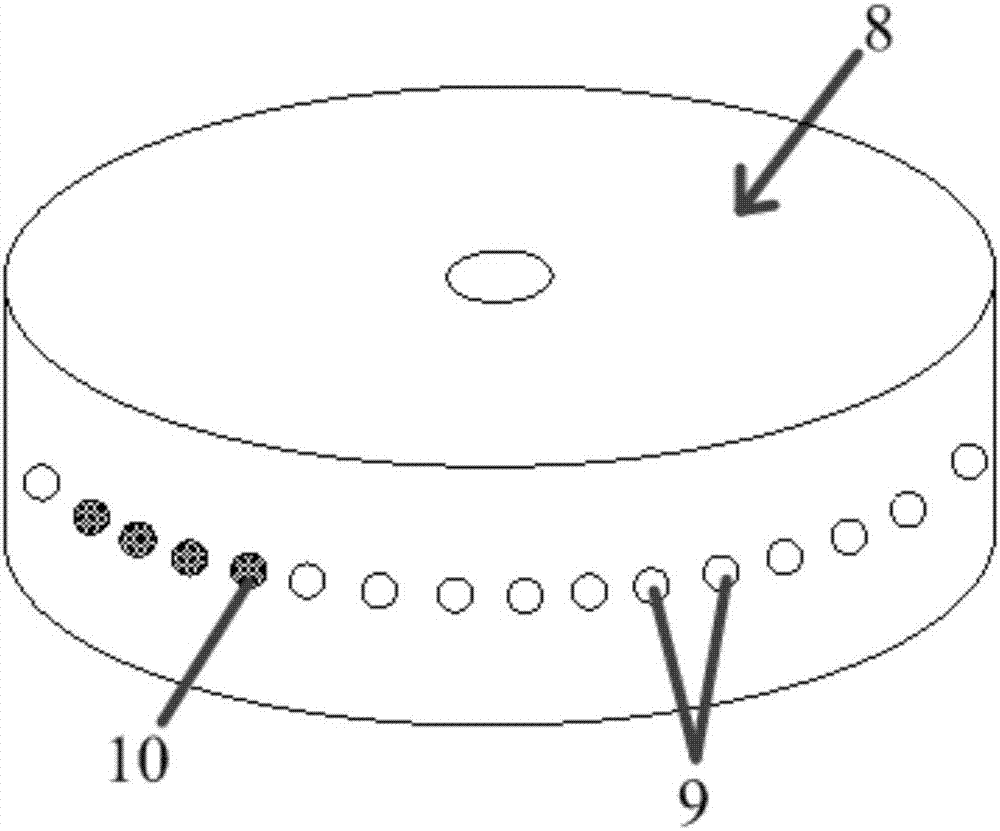

[0045]The launch head 3 is arranged on the front end of the projectile body 1, and it includes a signal receiver 5, a controller 6, an excitation structure 7 arranged in the cavity of the bullet shell 4 made of metal material, and a secondary power is accommodated. The disk-shaped power chamber 8 made of the thermal insulation material of the medium 13, the excitation structure is used to receive the excitation control command and excite the secondary power medium 5 in the power chamber 6, and the secondary power medium 5 is propellant; image 3 As shown, the disk-shaped power chamber 8 is provided with at least one injection channel 9 extendin...

Embodiment 2

[0052] Automatically track projectiles as bullets, which include:

[0053] The signal transmitter is pre-set on the tracked target and is used to transmit position signals;

[0054] The projectile body 1 is provided with a primary motive medium 2 in the inner cavity of the projectile body 1;

[0055] The launch head 3 is arranged on the front end of the projectile body 1, and it includes a signal receiver 5, a controller 6, an excitation structure 7 arranged in the cavity of the bullet shell 4 made of metal material, and a secondary power is accommodated. The disk-shaped power chamber 8 made of the thermal insulation material of the medium 13, the excitation structure is used to receive the excitation control command and excite the secondary power medium 5 in the power chamber 6, and the secondary power medium 5 is propellant; image 3 As shown, the disk-shaped power chamber 8 is provided with at least one injection channel 9 extending to the outside of the side of the launch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com