Stress measuring instrument implementation method based on FBG (fiber bragg grating) sensor

A fiber grating technology and a realization method are applied in the measurement of force, measurement device, and force measurement by measuring the change of optical properties of materials when they are stressed. Practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

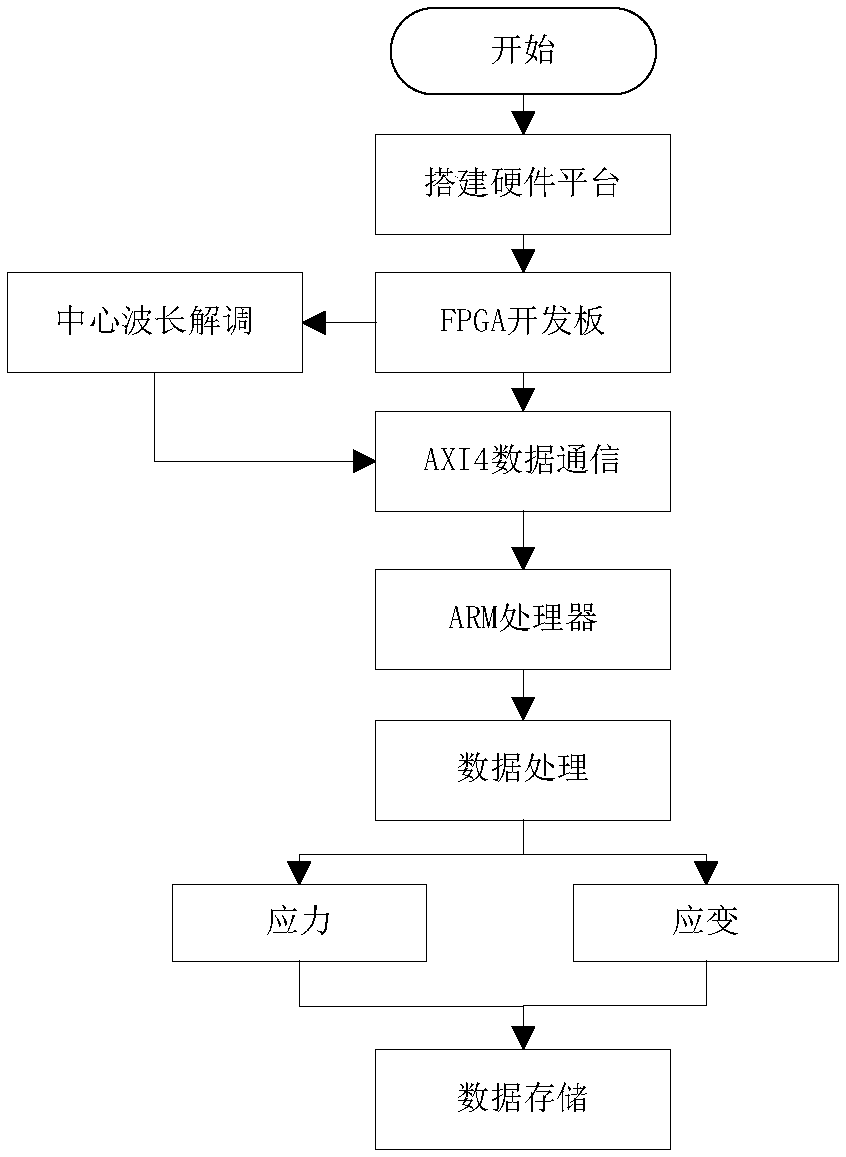

[0027] The present invention is based on a method for implementing a stress measuring instrument based on a fiber grating sensor, see figure 1 As shown, the specific steps are as follows:

[0028] Step 1, build the hardware platform of the structural health monitoring system based on the fiber grating sensor, and determine the development board, programming language and processor used by the hardware platform; the present invention uses the integrated development board Miz702 (Nanjing Millian Electronics) whose model is XC7Z020-1CLG484I , the integrated development board uses a platform combining FPGA and ARM processor, and uses the development software version "Vivado2015.4" for development;

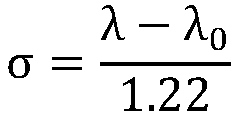

[0029] Step 2, the system of the present invention demodulates the center wavelength of the fiber grating sensor with FPGA, and calculates the offset of the center wavelength of the fiber grating sensor. At the same time, the demodulated data is stored. The light from the broadband li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com