Gas turbine compressor vibration simulation test bed

A technology for simulating test benches and gas turbines, which is applied in gas turbine engine testing, vibration testing, jet engine testing, etc. It can solve problems such as simulation test bench simulation tests, and achieve effects that are not easy to reproduce and have complex vibration components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

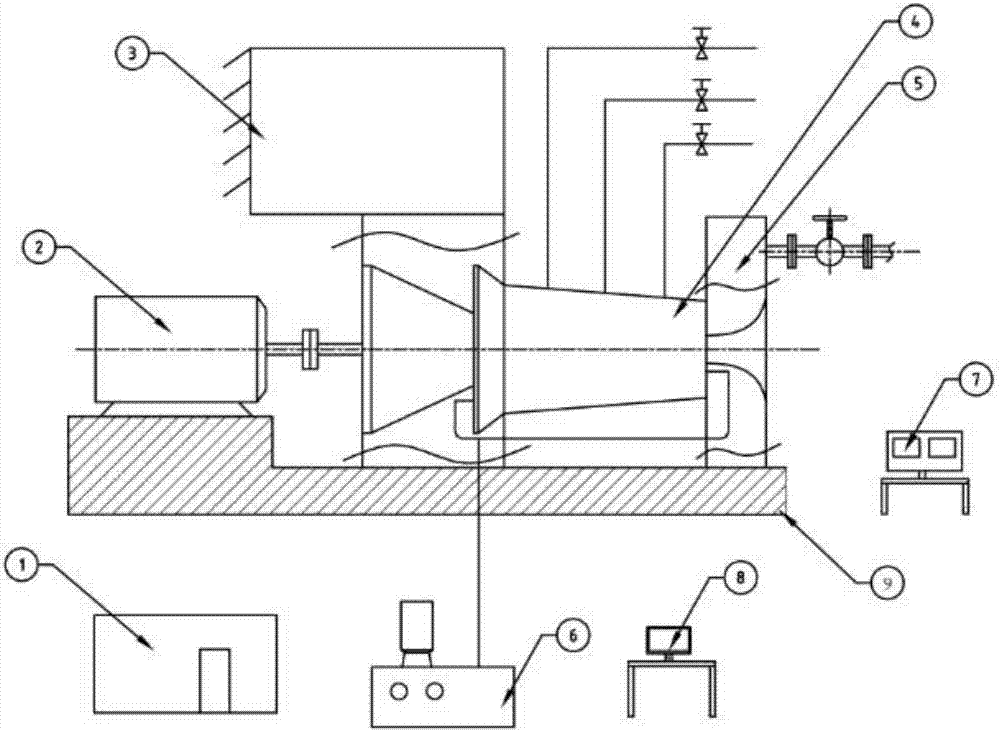

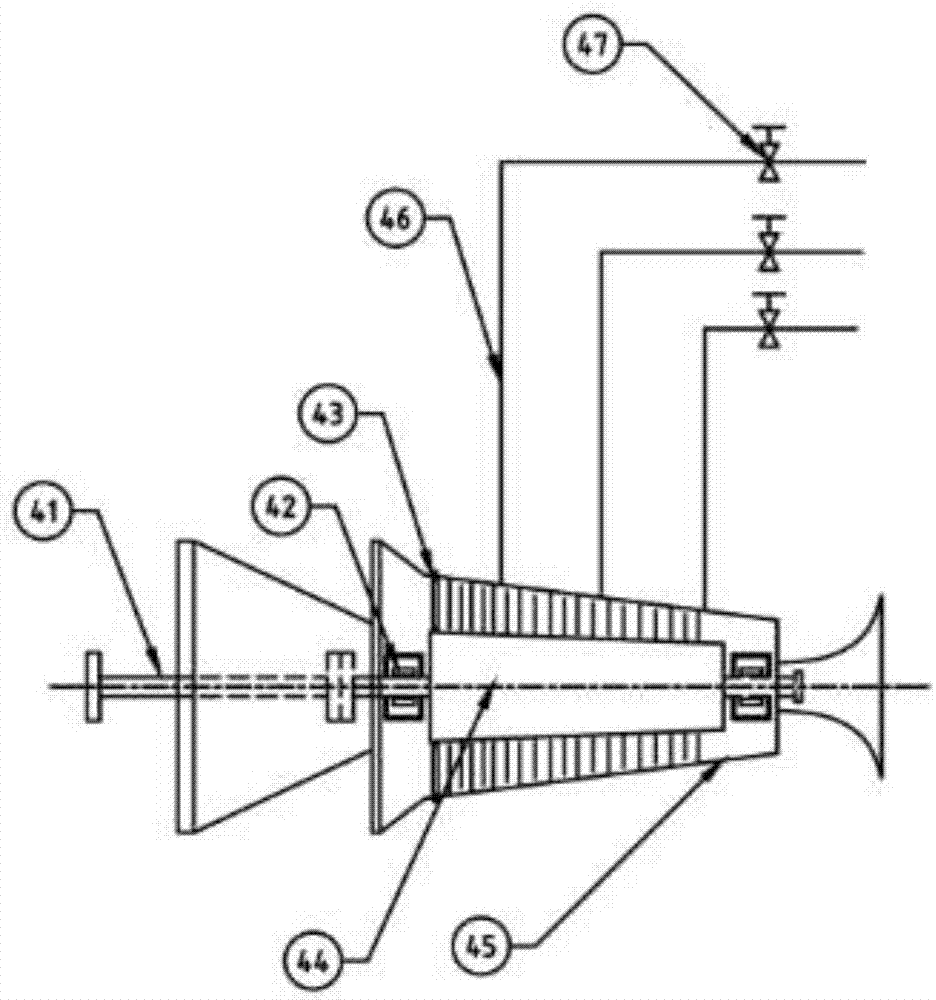

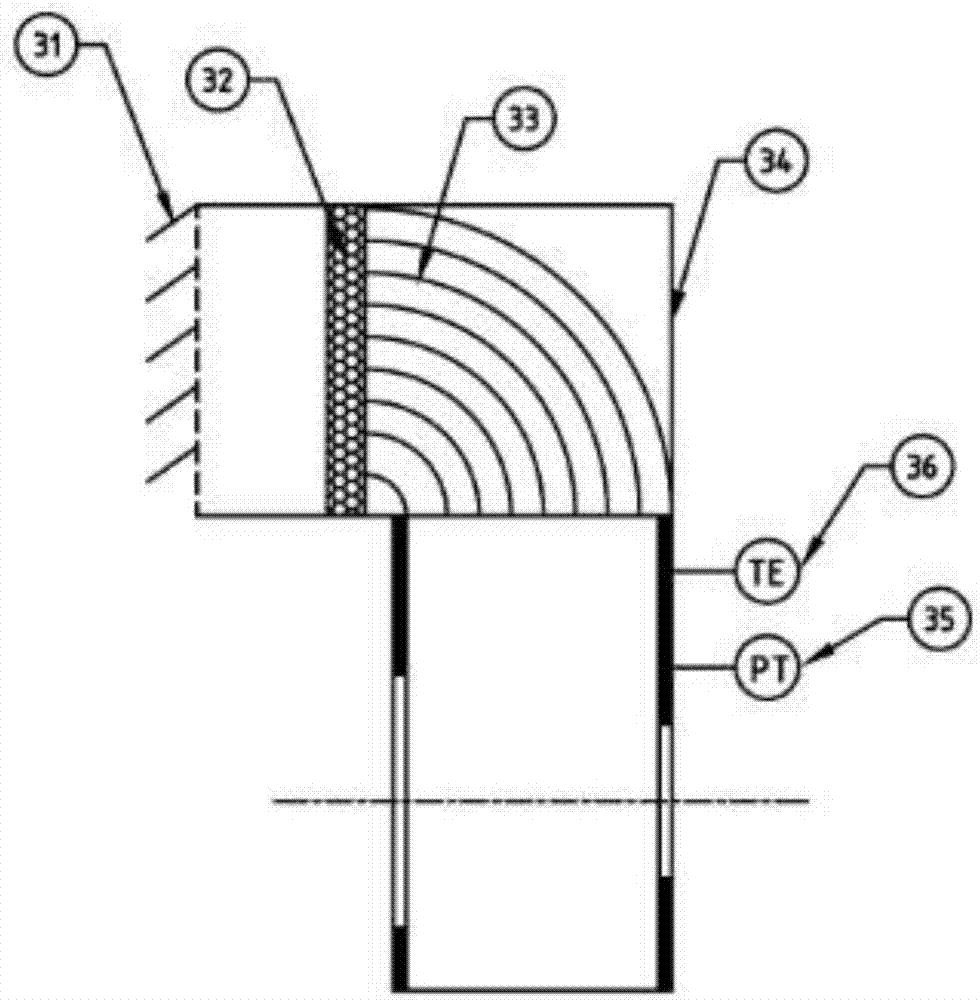

[0032] exist figure 1 Among them, the SFC variable frequency starter 1 outputs variable frequency alternating current to the starter motor 2, and the starter motor 2 and the test compressor 4 are coaxially connected through a coupling 41 and well aligned. At the same time, the test compressor 4 is well dynamically balanced. Plant influences due to rotor unbalance and rotor misalignment are thereby excluded. The exhaust port of the intake component 3 is connected to the inlet of the test compressor 2 . The exhaust port of the test compressor 4 is connected to the inlet of the exhaust component. In the test, the starter motor 2 driven by the SFC variable frequency starter 1 can run stably at any speed between 0 and 10000 rpm. Such as figure 2 As shown, the test compressor 4 has three-stage compressor air extraction pipelines, the three air extraction pipelines are respectively 461, 462, and 463, and each air extraction pipeline is provided with an air extraction valve, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com