Method for separating minor faults in industrial processes

A technology of industrial process and separation method, which is applied in the field of separation of micro-faults in industrial process, can solve problems such as wrong separation results, and achieve the effect of being convenient for practical application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

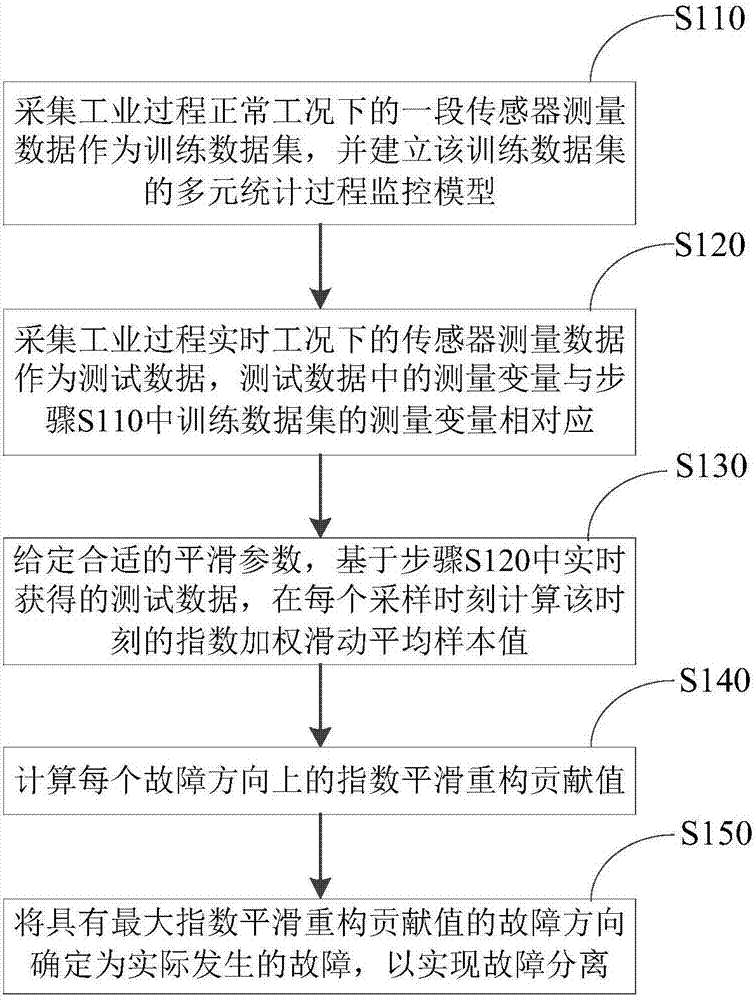

[0034] Such as figure 1 As shown, a separation method for micro-faults in industrial processes, including:

[0035] Step 1: collect a section of sensor measurement data under normal working conditions of the industrial process as a training data set, and establish a multivariate statistical process monitoring model for the training data set;

[0036] The sensor measurement data under normal working conditions of the industrial process is collected as a training data set, stored as a two-dimensional data matrix, and the data matrix is standardized. Specifically, the collected training data is stored as a two-dimensional data matrix X 0 ∈ R N×m , where each row represents a sample, each column represents a sensor variable, and the data matrix contains N samples and m variables. to x 0 Standardize, that is, X 0 Each co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com